Rotation angle detection device and electric motor with rotation angle detection device equipped with same

A rotation angle detection, electric motor technology, applied in the direction of measuring devices, electromechanical devices, electric components, etc., can solve the problem of large outer diameter, and achieve the effect of reducing outer diameter, reducing thickness, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

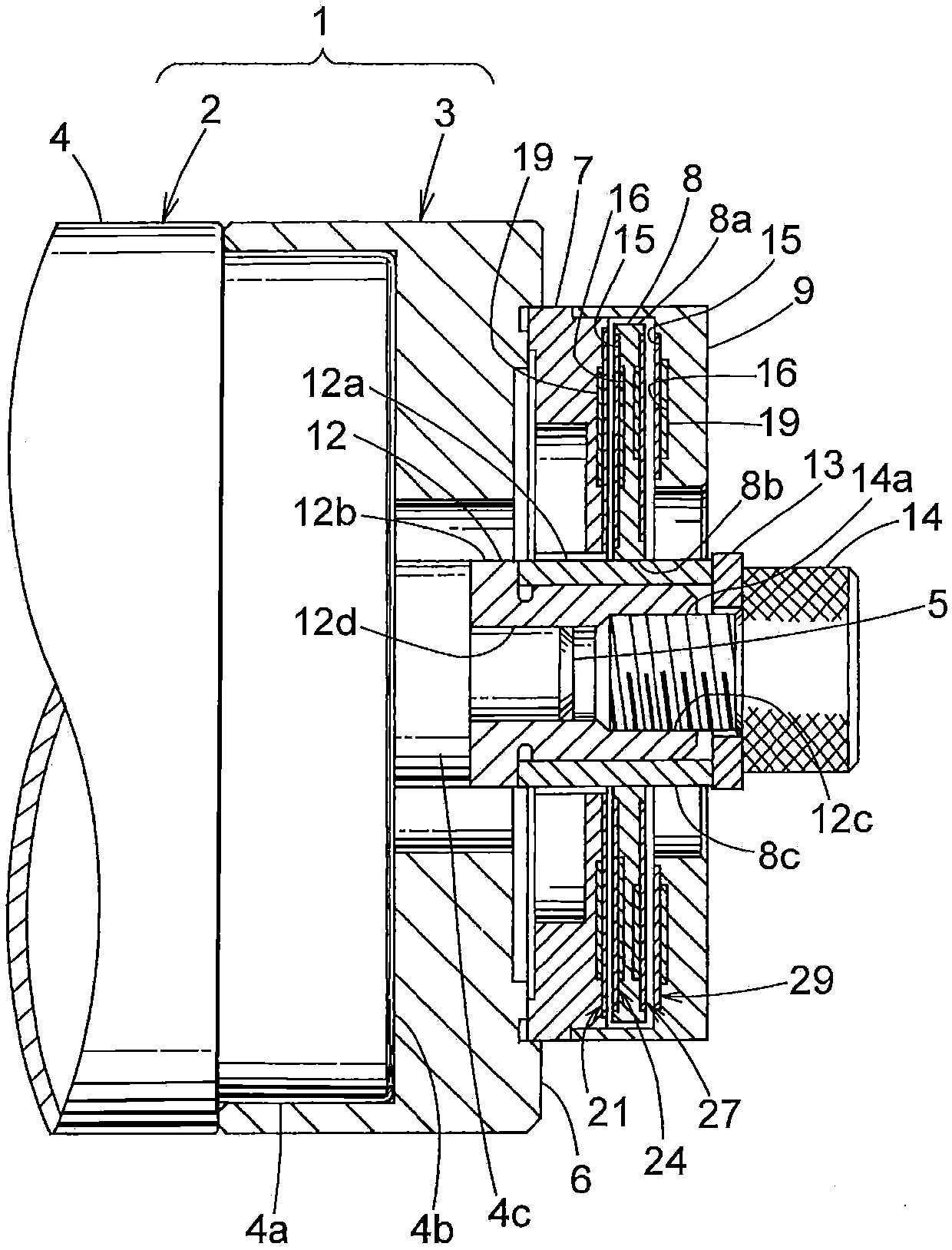

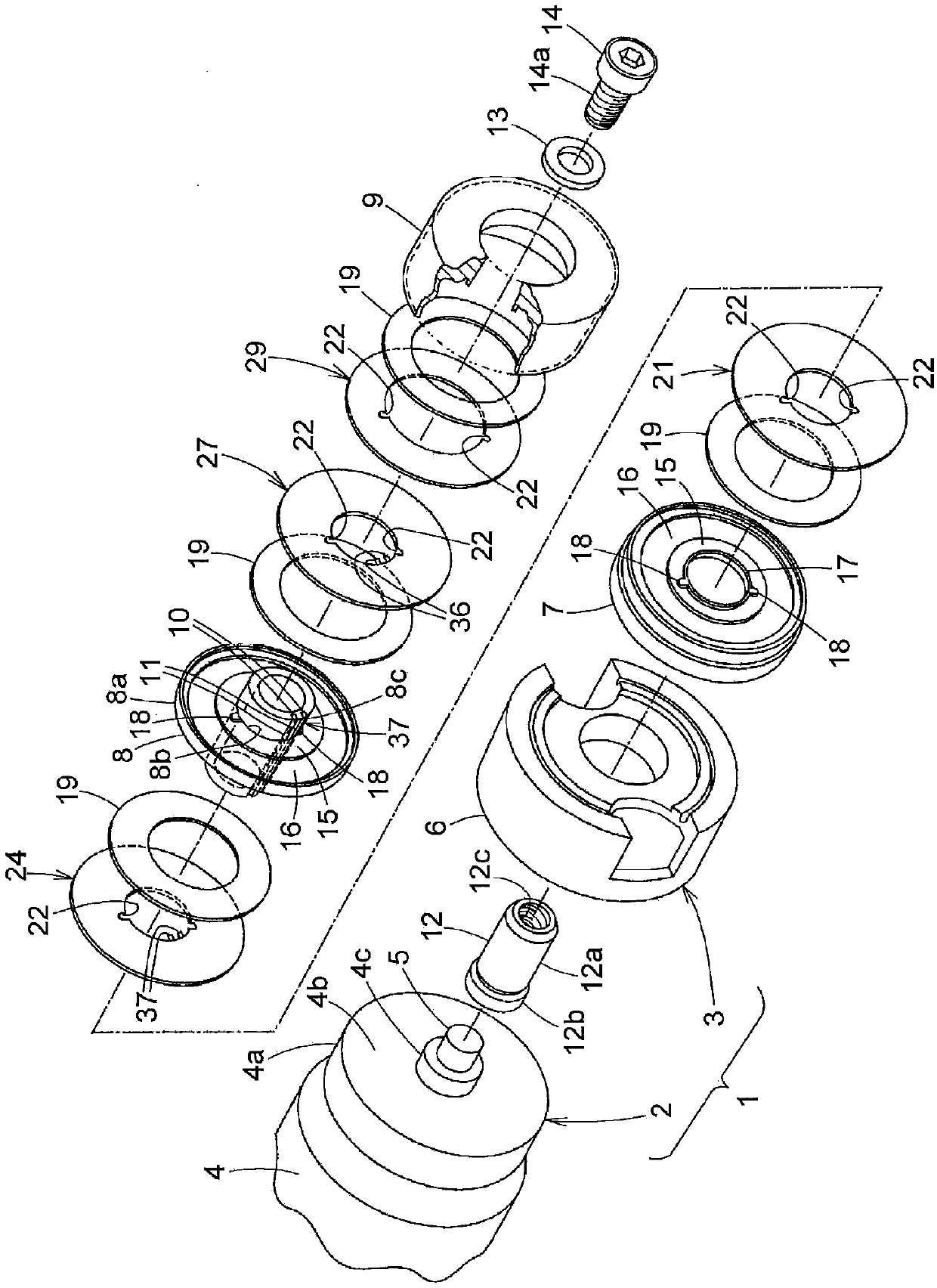

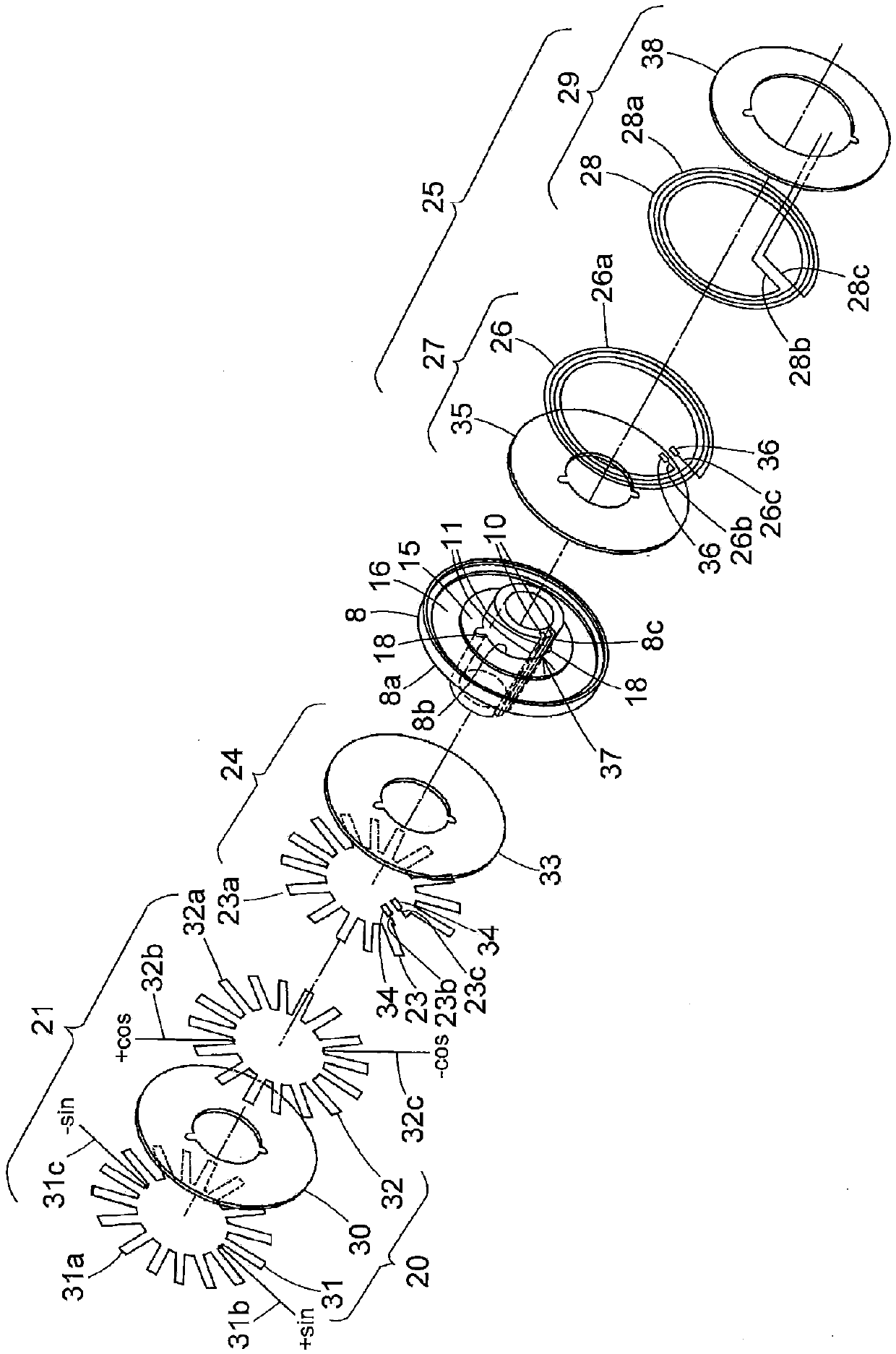

[0070] combine Figure 1 to Figure 5 A first embodiment of a rotation angle detection device and an electric motor having the rotation angle detection device according to the present invention will be described.

[0071] Such as figure 1 and figure 2 As shown in , an electric motor 1 with a rotation angle detection device includes an electric motor 2 shown as a small DC motor and a rotation angle detection device 3 mounted on an end portion of the electric motor 2 .

[0072] The electric motor 2 has a horizontal cylindrical motor case 4 . The case 4 includes a reduced-diameter portion 4a formed on an end portion thereof, an end plate 4b closing an end opening of the reduced-diameter portion 4a, and a boss portion 4c formed at a central portion of the end plate 4b. The boss portion 4 c rotatably supports the rotary shaft 5 such that an end portion of the rotary shaft 5 protrudes outward from the motor case 4 .

[0073] Since other components of the electric motor 2 are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com