Rotation angle detection sensor, torque detection sensor, and power transmission device

A technology of rotation angle detection and power transmission device, which is applied in the direction of measurement device, force/torque/work measurement instrument, torque measurement, etc., which can solve the problem that the strain gauge cannot detect the rotation angle input to the flexible external gear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

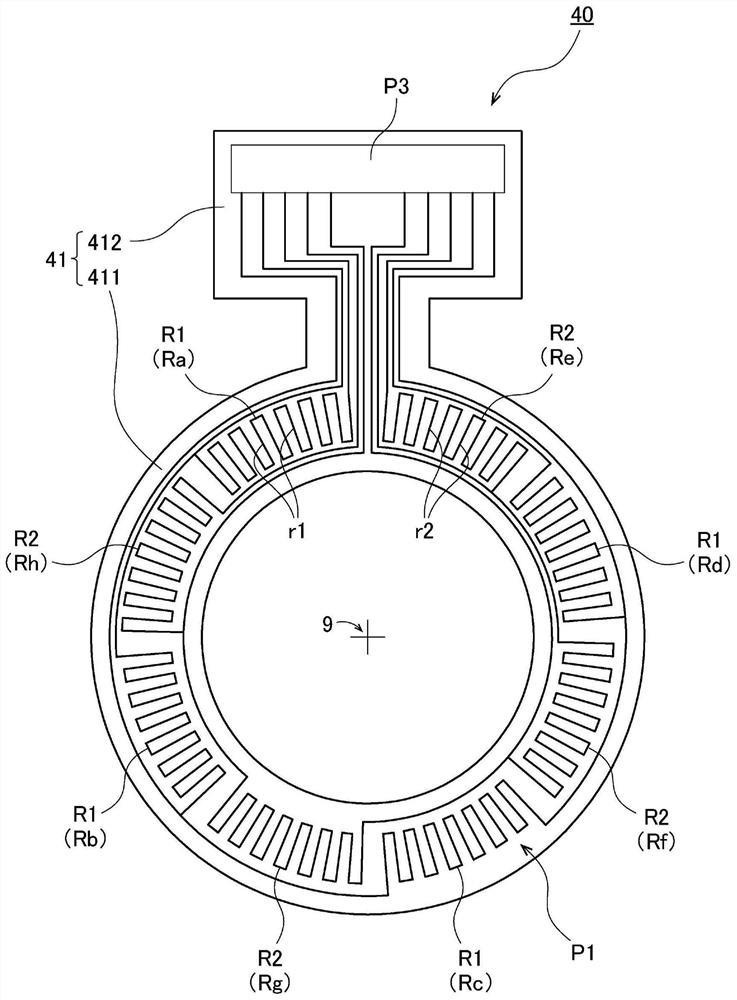

[0022] Hereinafter, illustrated embodiments of the present application will be described with reference to the accompanying drawings. In addition, in this application, the direction parallel to the central axis of the power transmission device is called "axial direction", the direction perpendicular to the central axis of the power transmission device is called "radial direction", and the direction along the power transmission The direction of the arc centered on the central axis of the device is referred to as the "circumferential direction". However, the above-mentioned "parallel direction" also includes substantially parallel directions. In addition, the above-mentioned "vertical direction" also includes a substantially vertical direction.

[0023]

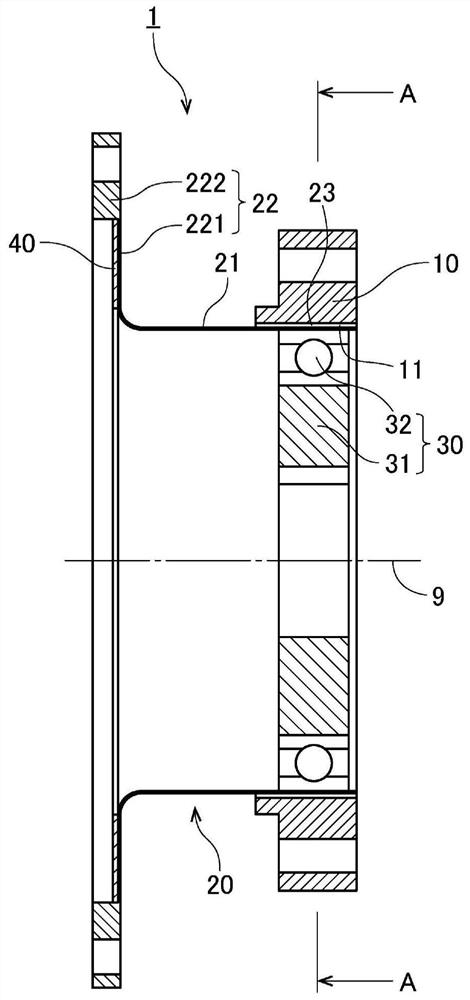

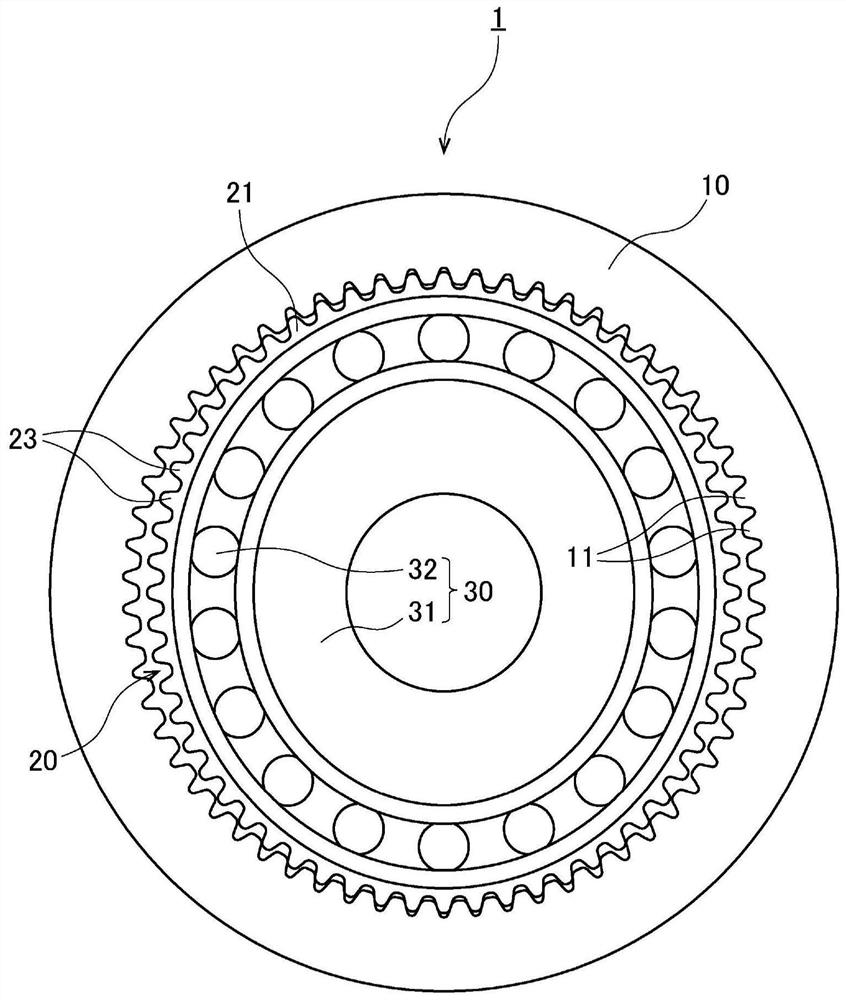

[0024] figure 1 It is a longitudinal sectional view of the power transmission device 1 of the first embodiment. figure 2 From figure 1 A cross-sectional view of the power transmission device 1 viewed from position A-A of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com