pump device

A pump device and pump chamber technology, applied in pump devices, electromechanical devices, pumps, etc., can solve the problems of low magnetic flux density and inability to detect the rotation angle of the rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

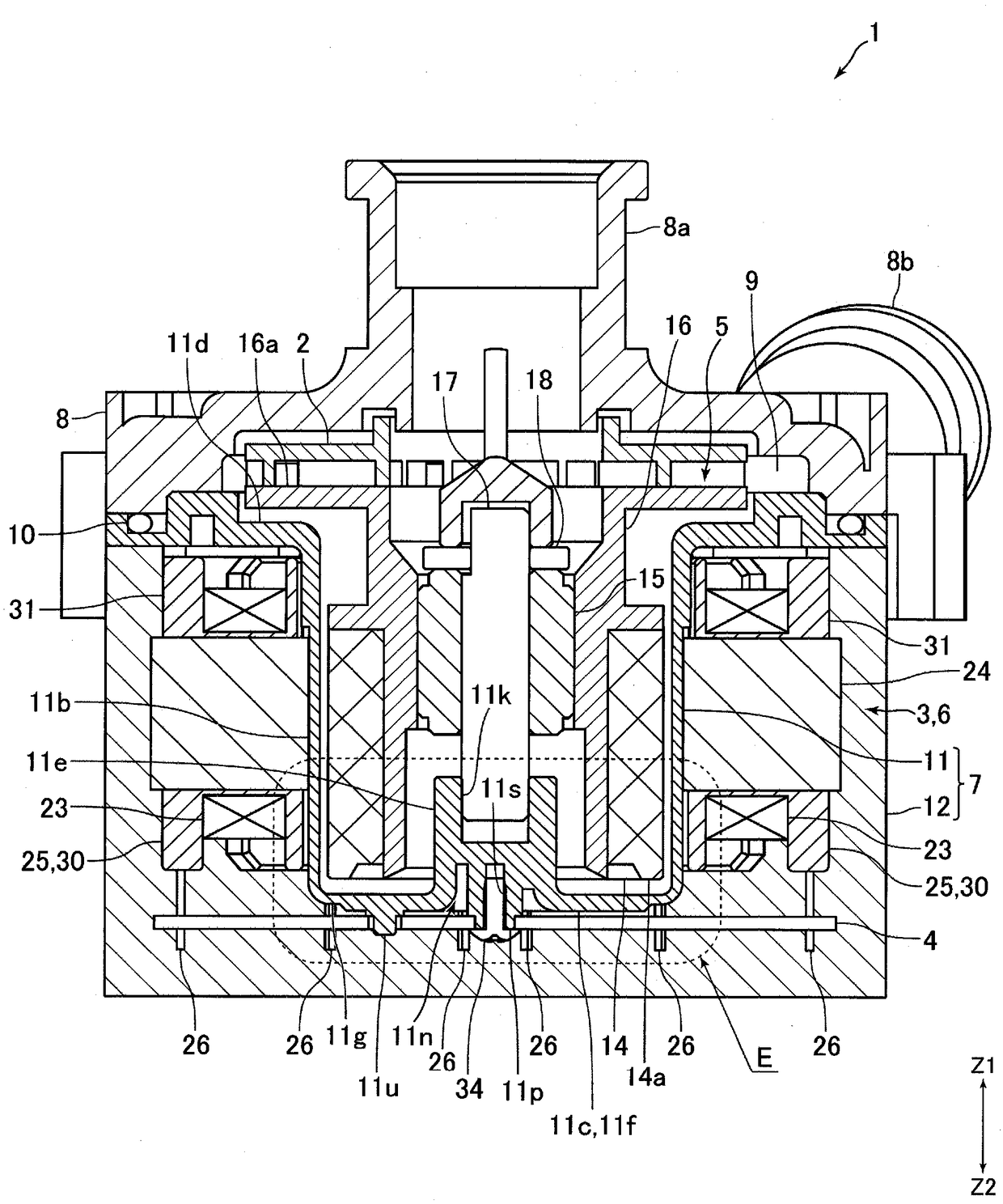

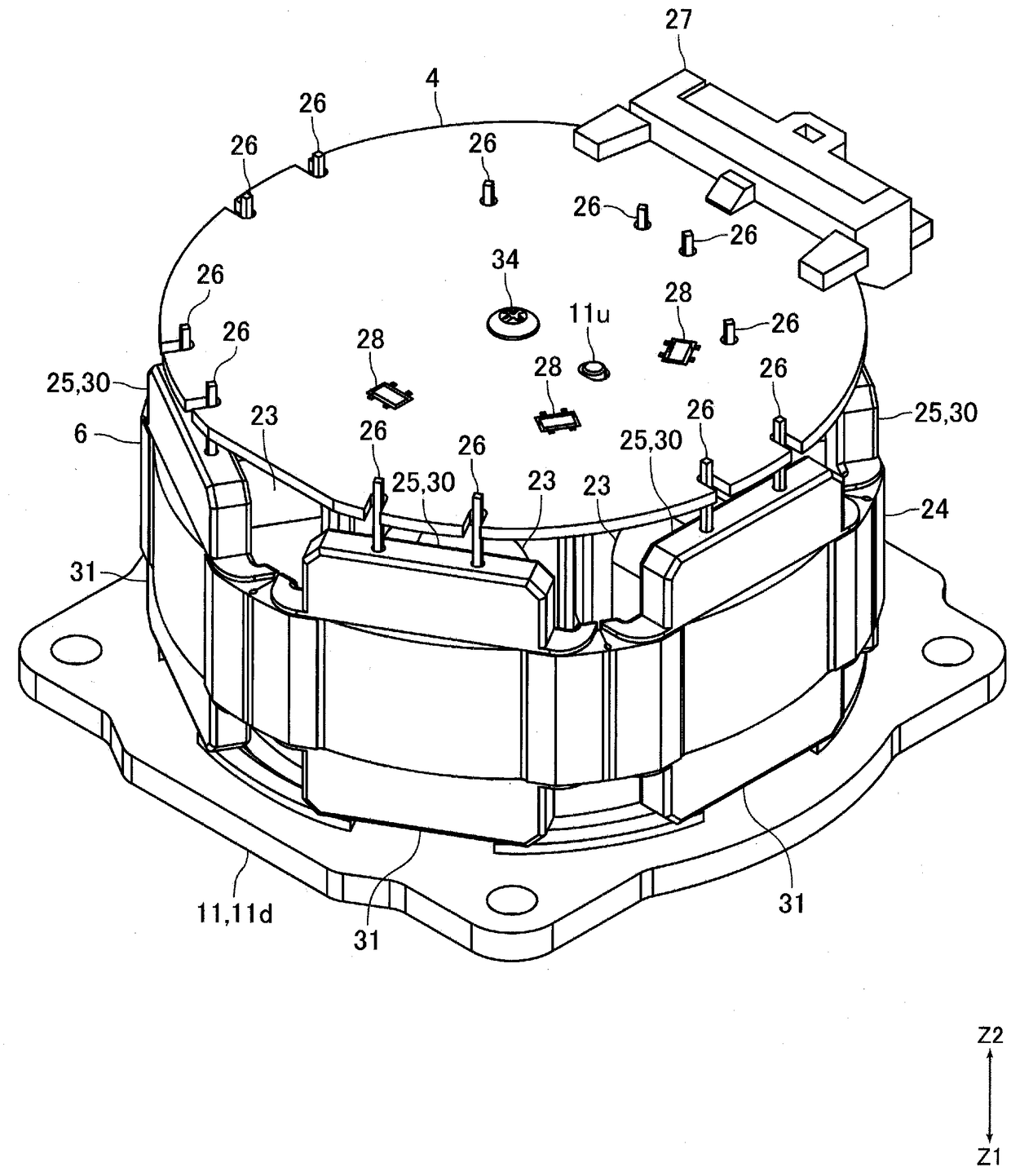

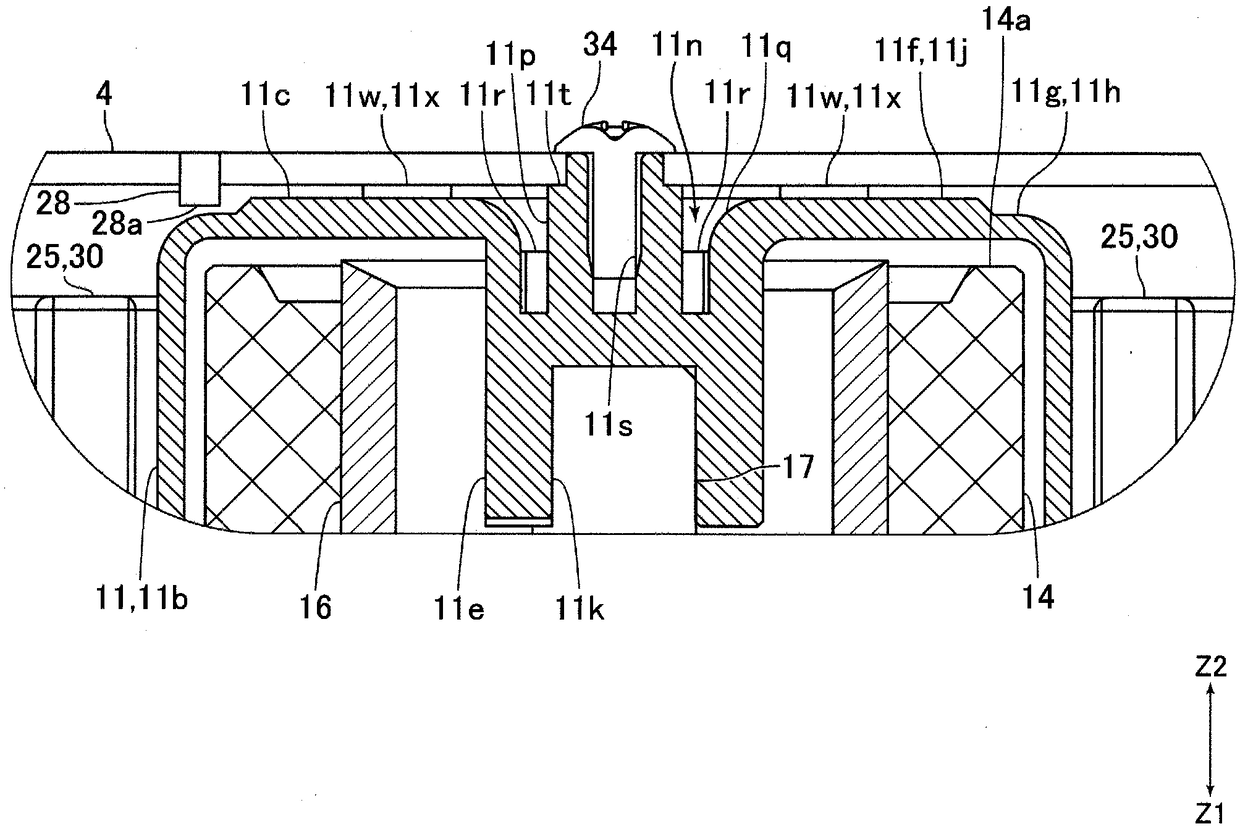

[0054] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described.

[0055] (The overall structure of the pump unit)

[0056] figure 1 It is a cross-sectional view of the pump device 1 according to the embodiment of the present invention. figure 2 yes figure 1 The perspective view of the circuit board 4, the stator 6, and the partition member 11 shown. image 3 is shown from the other direction figure 1 An enlarged cross-sectional view of part E. Also, in the following description, the figure 1 The upper side (Z1 direction side) as the "upper" side, the figure 1 The lower side (Z2 direction side) as the "lower" side.

[0057] The pump device 1 of the present embodiment is a type of pump called a sealed pump (sealed motor pump), and has: an impeller 2 ; a motor 3 for rotating the impeller 2 ; and a circuit board 4 for controlling the motor 3 . The motor 3 is composed of a rotor 5 and a stator 6 . The impeller 2 , the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com