A prefabricated steel structure building system and its construction method

A steel structure and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems that affect the overall building life and complicated construction, and achieve the effect of easy control of construction quality, fast construction speed and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

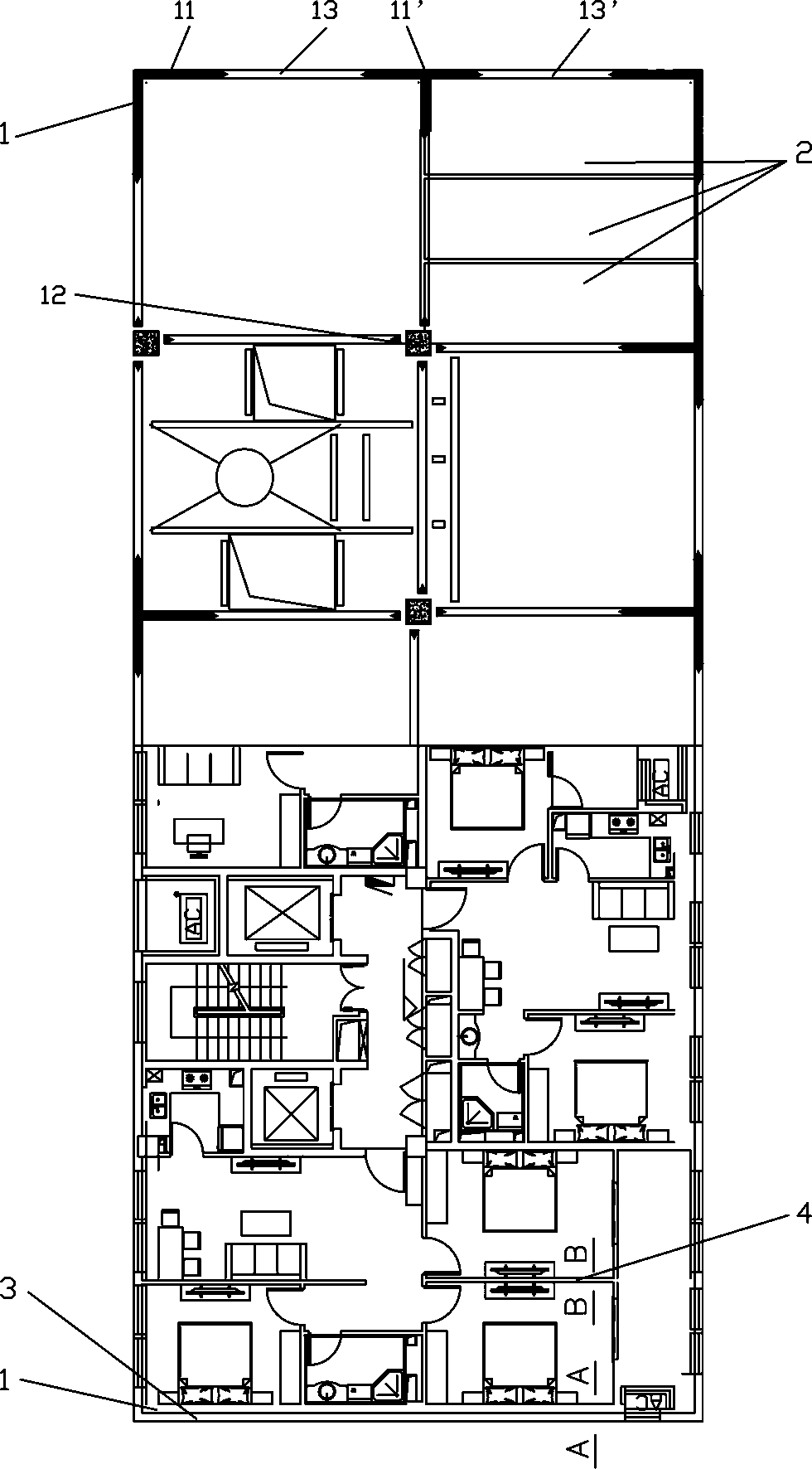

[0045] See Figure 1 ~ Figure 5 , A prefabricated steel structure building system of the present invention includes:

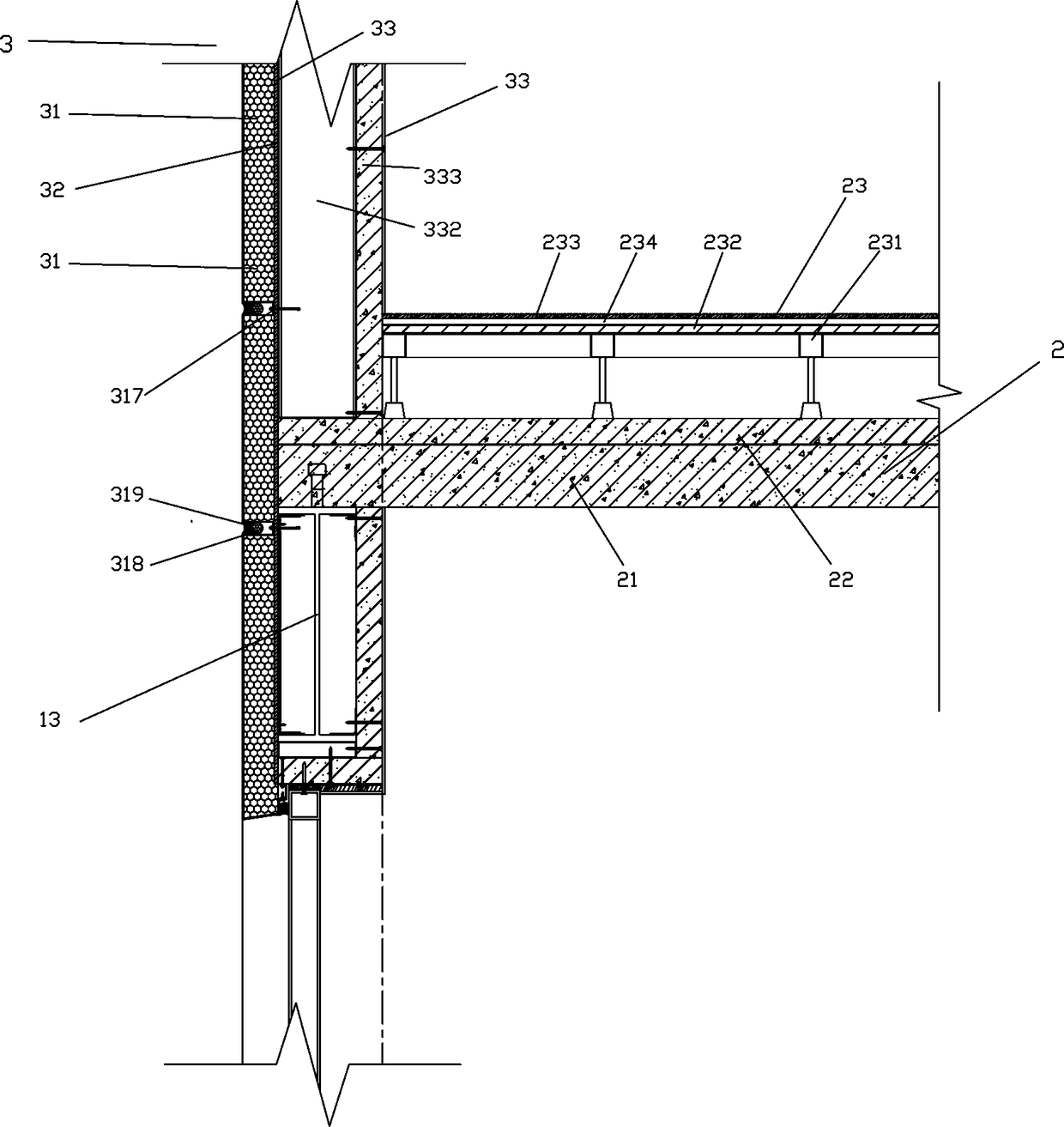

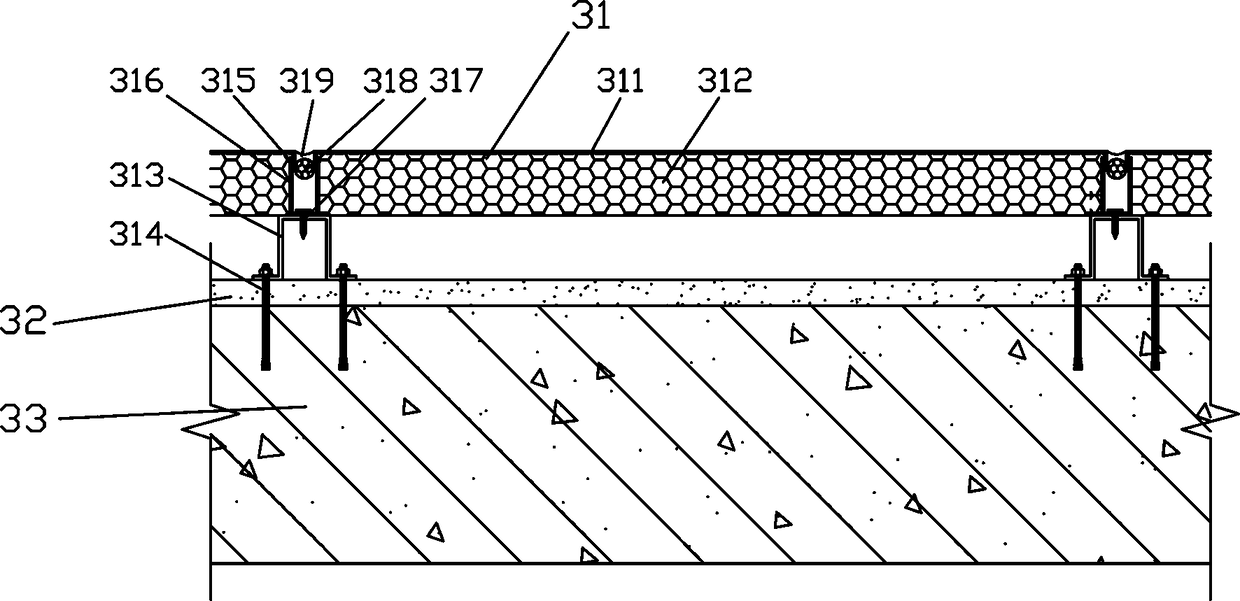

[0046] The steel frame system 1 includes several double-layer steel plate concrete composite shear walls 11, 11', several steel tube concrete columns 12, 12’, and several I-shaped steel beams 13, 13’; the double-layer steel plate concrete composite shear Between the walls 11 and 11' and between the double-layer steel plate concrete composite shear wall 11 and the concrete-filled steel tube column 12 are connected by I-shaped steel beams 13, 13';

[0047] Assemble the monolithic floor system 2, using the I-shaped steel beam 13 in the steel structure skeleton system 1 as a support, erected on the steel structure skeleton system 1, which in turn includes a precast concrete floor 21, Cast-in-place concrete laminated layer 22 and raised floor layer 23;

[0048] The prefabricated exterior wall system 3 is arranged on the outer side of the steel structure framework system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com