Carbon fiber prepreg fabric for repairing and reinforcing structure

A carbon fiber prepreg and structure technology, which is applied in fabrics, building structures, textiles, etc., can solve problems such as non-insulation and irreparable problems, and achieve the effects of increased strength, convenient construction, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

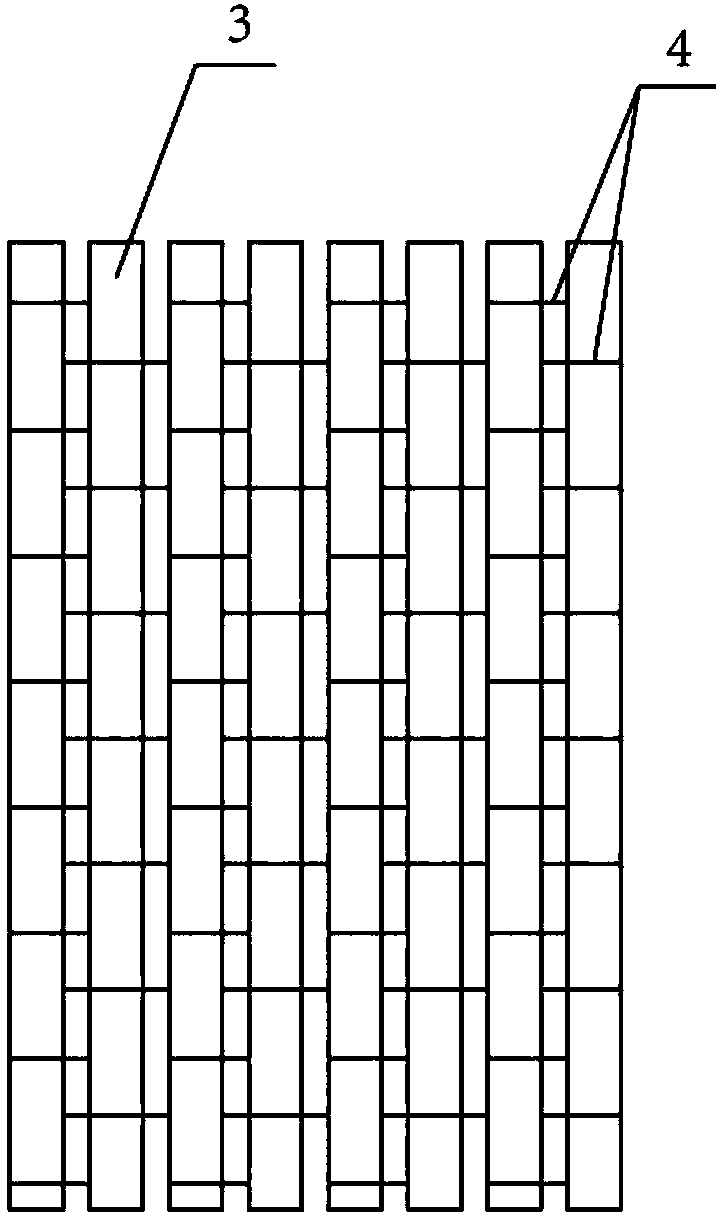

[0012] 1. Surface treatment: remove the laitance, oil, and impurities on the concrete surface of the pasting part. If there are honeycombs and cracks on the surface, they should be repaired to expose the structure body, blow it off, and wipe it with acetone. Wipe off the floating ash on the surface with carbon fiber material. 2. Brushing the primer: apply the primer that has been fully mixed in proportion to the concrete surface evenly. 3. Repair and leveling: After the above process, if there is any unevenness on the concrete surface, use repair glue to level it. 4. Glue preparation: Prepare the adhesive glue according to the weighing ratio, stir the groups A and B separately before mixing, and then fully stir after mixing. 5. Paste carbon fiber: cut the present invention according to the size required by the design, and apply the prepared adhesive evenly on the concrete surface of the pasted part. On the basis of coating the adhesive glue, the cut-out invention is rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com