Exterior wall thermal insulation board with high performance and preparation process thereof

An external wall thermal insulation board and a preparation process technology, applied in the field of external wall thermal insulation boards, can solve the problems of high density, unsatisfactory and poor strength of thermal insulation boards, and achieve the effects of low density, strong plasticity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A high-performance external wall insulation board is composed of the following raw materials in parts by weight: 100-200 parts by weight of perlite, 50-100 parts of adhesive, 50-100 parts of hydrogen peroxide, 10-20 parts of calcium stearate, 5-10 parts of calcium formate, fluorine Sodium silicate 10-20, tensile fiber 0.5-1, blast furnace slag 10-20, waterproofing agent 5-10, wherein the binder in the raw materials is water glass, the waterproofing agent is NanothixB1490, and the tensile fiber is polypropylene .

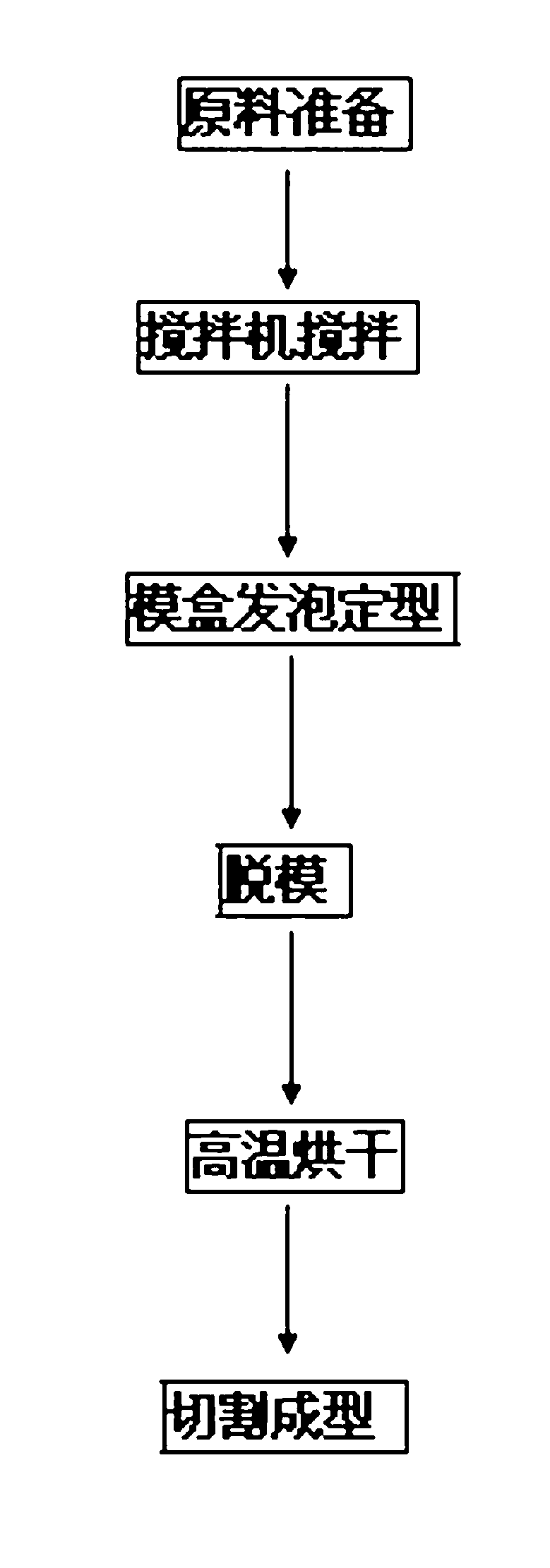

[0019] The preparation process of the above-mentioned high-performance external wall insulation board comprises the following steps:

[0020] (1) Preparation of raw materials: Mix the above raw materials in proportion, stir for 3 to 5 minutes, and the stirring speed is 300 rpm;

[0021] (2) Foaming and shaping of the mold box: After the raw materials prepared in step (1) are foamed and shaped for 2 to 3 hours, the mold box is demoulded, and then enters a dryi...

Embodiment 2

[0025] A high-performance external wall insulation board, composed of the following raw materials in parts by weight: perlite 200, adhesive 100, hydrogen peroxide 100, calcium stearate 20, calcium formate 10, sodium fluorosilicate 20, tensile fiber 1, Blast furnace slag 20, waterproofing agent 10.

[0026] Preparation method is the same as embodiment 1

[0027] Produced product parameters: Density: 160kg / m 3 Hydrophobic rate: 98%

[0028] Compressive strength: 0.4MPa Flexural strength: 0.2 + Thermal conductivity 0.055W / (m . k)

Embodiment 3

[0030] A high-performance external wall insulation board, which is composed of the following raw materials in parts by weight: perlite 150, adhesive 50-100, hydrogen peroxide 80, calcium stearate 15, calcium formate 8, sodium fluorosilicate 15, tensile fiber 0.8, blast furnace slag 15, waterproofing agent 8.

[0031] Preparation method is the same as embodiment 1

[0032] Produced product parameters: Density: 120kg / m 3 Hydrophobic rate: 98%

[0033] Compressive strength: 0.35MPa Flexural strength: 0.2 + Thermal conductivity 0.051W / (m . k)

[0034] The insulation board is directly connected with the base surface of the outer wall by using polymer adhesive mortar and engineering plastic connectors in the on-site construction, which realizes factory production, assembly construction, standardized quality assurance, and at the same time achieves high efficiency, energy saving, safety and reliability, and performance quality Long-term stable engineering effect (according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com