Construction method and support system of assembleable and recoverable deep foundation pit support system

A deep foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of unresolved, non-recyclable materials, etc., achieve low cost, be conducive to environmental protection, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

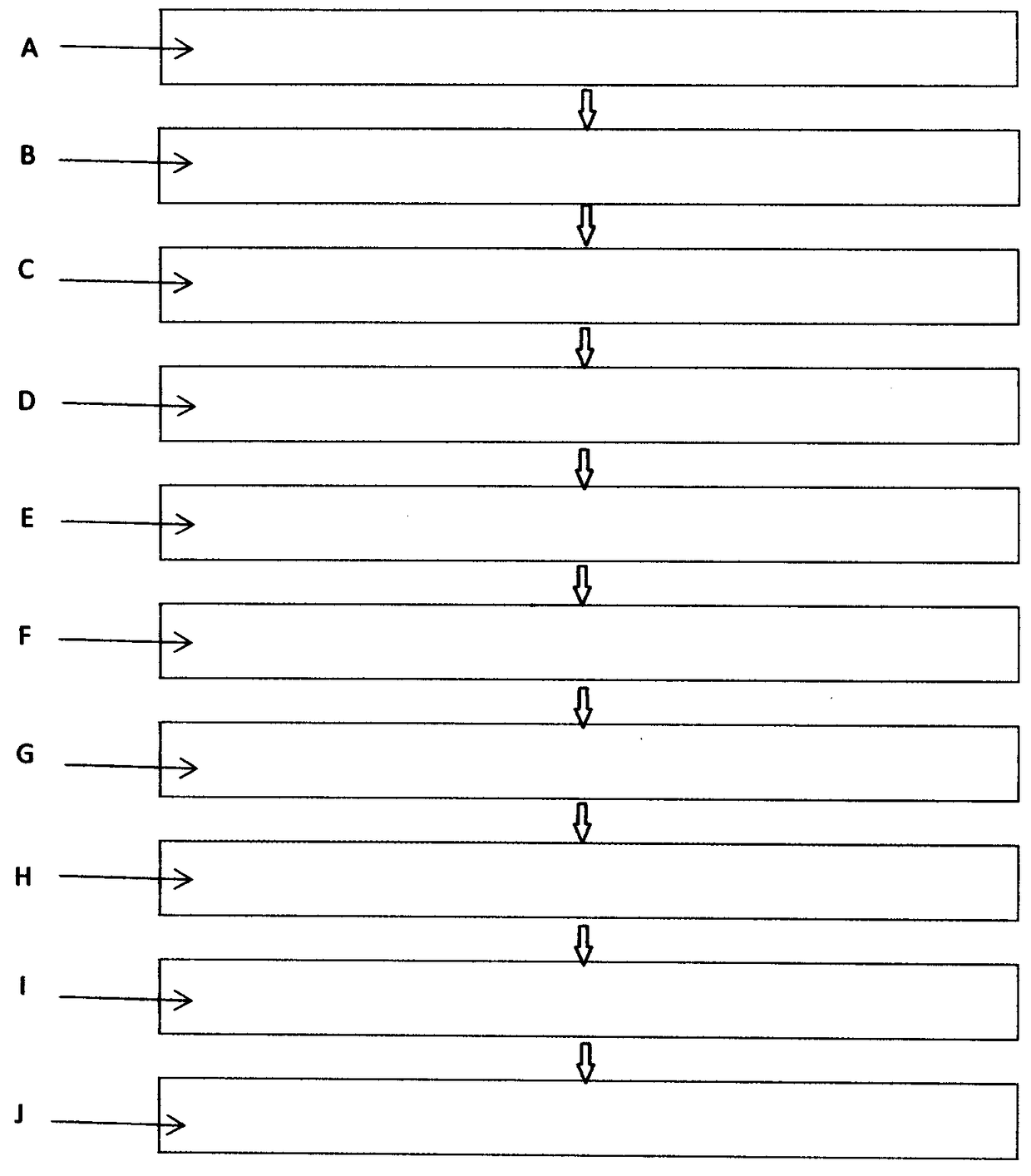

[0027] Embodiment 1: as figure 1 as shown, figure 1 Mark A represents step ①, which is to form a row of vertical holes, and place a vertical support in each vertical hole; mark B represents step ②, which is to excavate the first earthwork to form the first anchor hole or Anchor cable hole, that is, the first anchor (cable) hole; mark C represents step ③, that is, the second anchor (cable) hole is formed, and the recyclable anchor (cable) is lowered (put in) and grouted ; Mark D represents step ④, that is, the first transverse support beam is installed at the anchor rod (cable) position of step 2, and prestress is applied, and the second transverse support beam is installed at the anchor rod (cable) position of step ③, and prestress is applied. Stress; mark E represents step ⑤, that is, install the first layer of vertical baffle between the first horizontal support beam and the second horizontal support beam formed in step ④, for the first anchor rod or anchor cable, for the s...

Embodiment 2

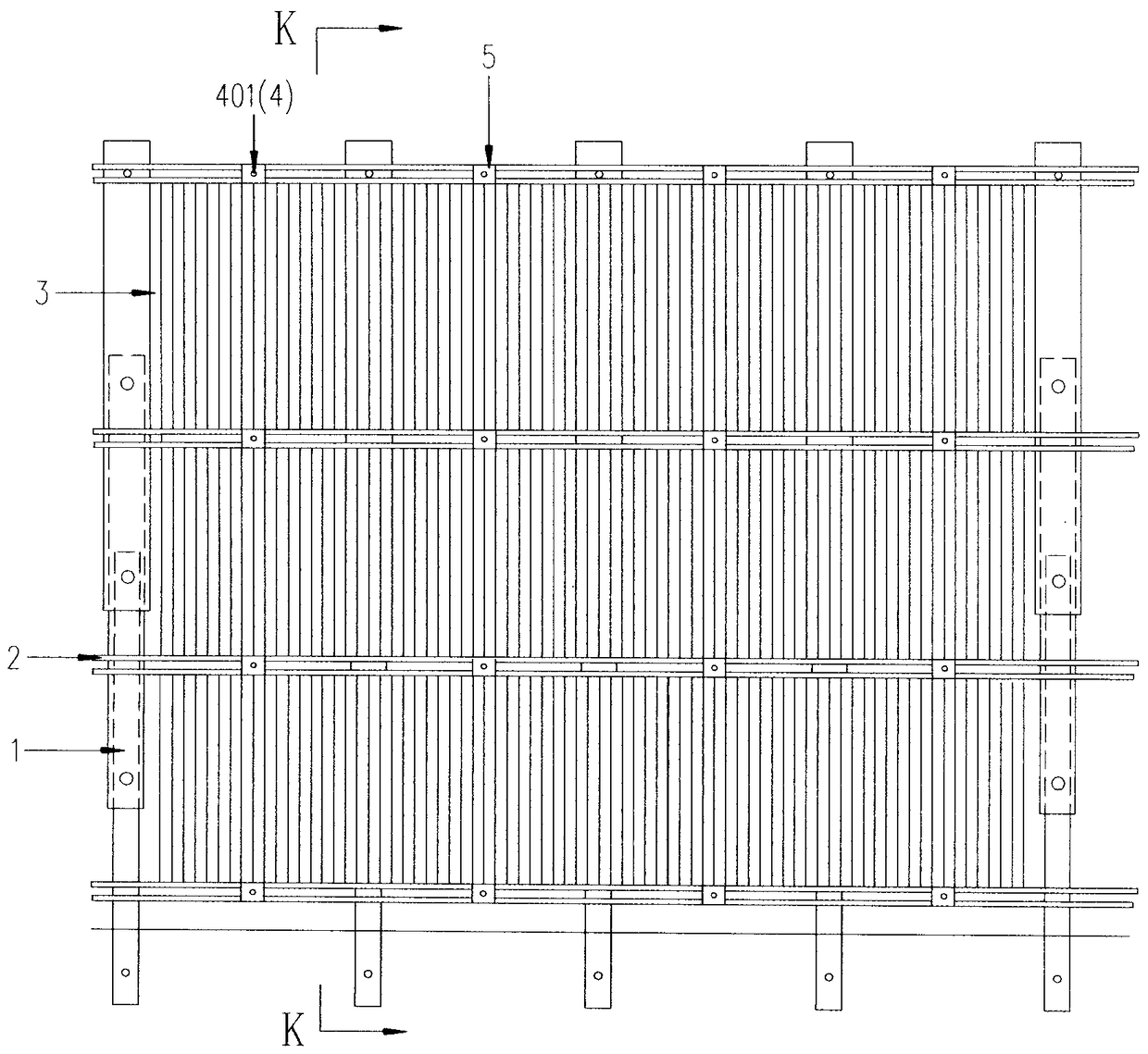

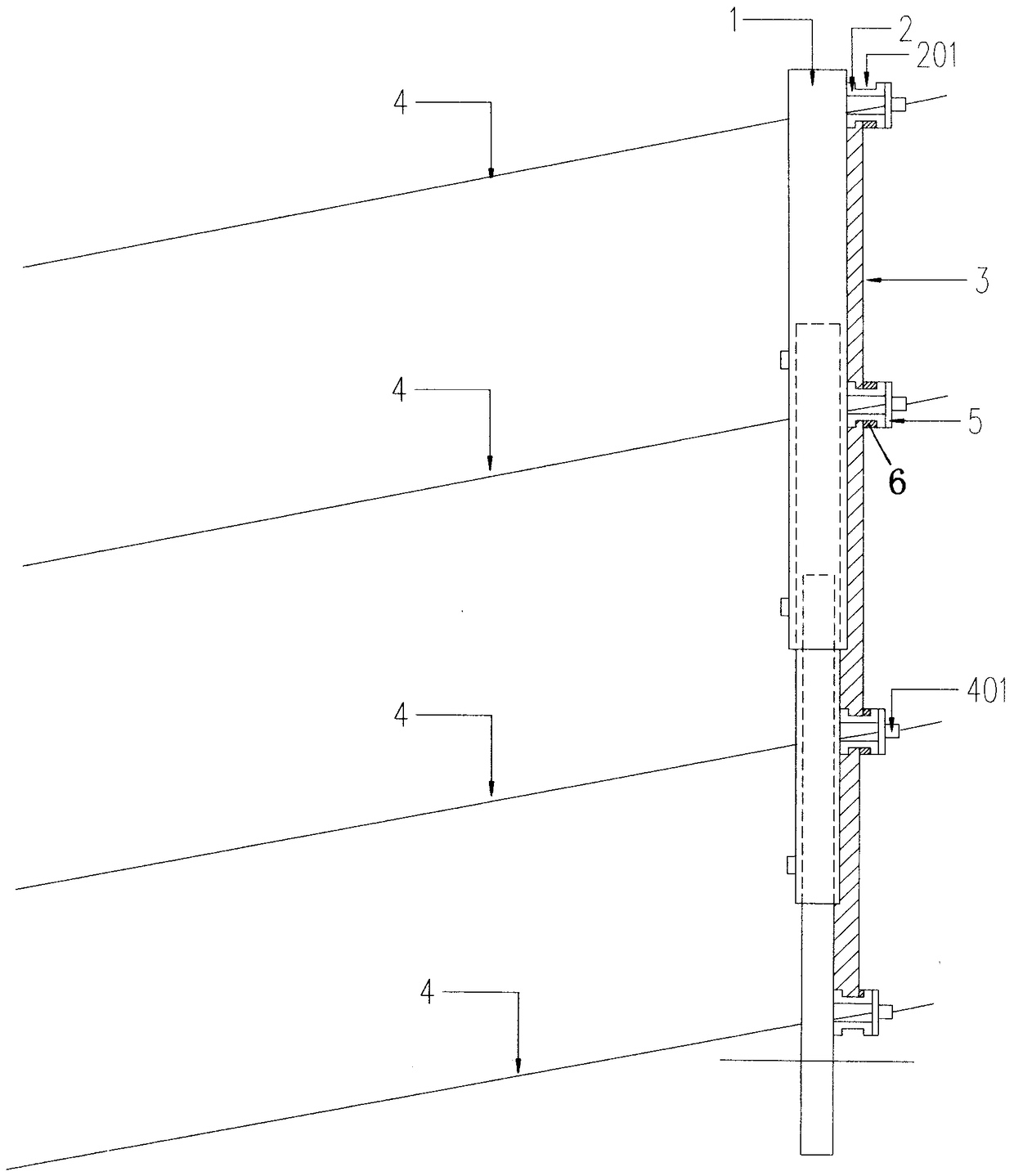

[0041] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the assembleable and recyclable deep foundation pit support system of the present invention has multiple vertical supports 1 located in the soil body of the side wall of the foundation pit and whose outer wall is aligned with the side wall of the foundation pit, and located in the multi-channel vertical One of the multiple horizontal support beams 2 on the outside of the support body and limiting the multiple vertical support bodies, multiple vertical baffles (or multi-layer vertical baffles) 3, anchor rods and anchor cables 4 , the number of the anchor rods and the anchor cables is multiple (that is, one of the two support members of the plurality of anchor rods and the plurality of anchor cables is used). Multiple transverse support beams lean against the side walls of the foundation pit. Every transverse support beam 2 is all made of a plurality of channel steel sections, the length of each ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com