Assembled indoor exposed frame wall brick system and construction method thereof

A construction method and prefabricated technology, applied in covering/lining, construction, building structure, etc., can solve the problems of inability to meet the needs of prefabricated building decoration, and achieve the effect of simple manufacturing process, small workload and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

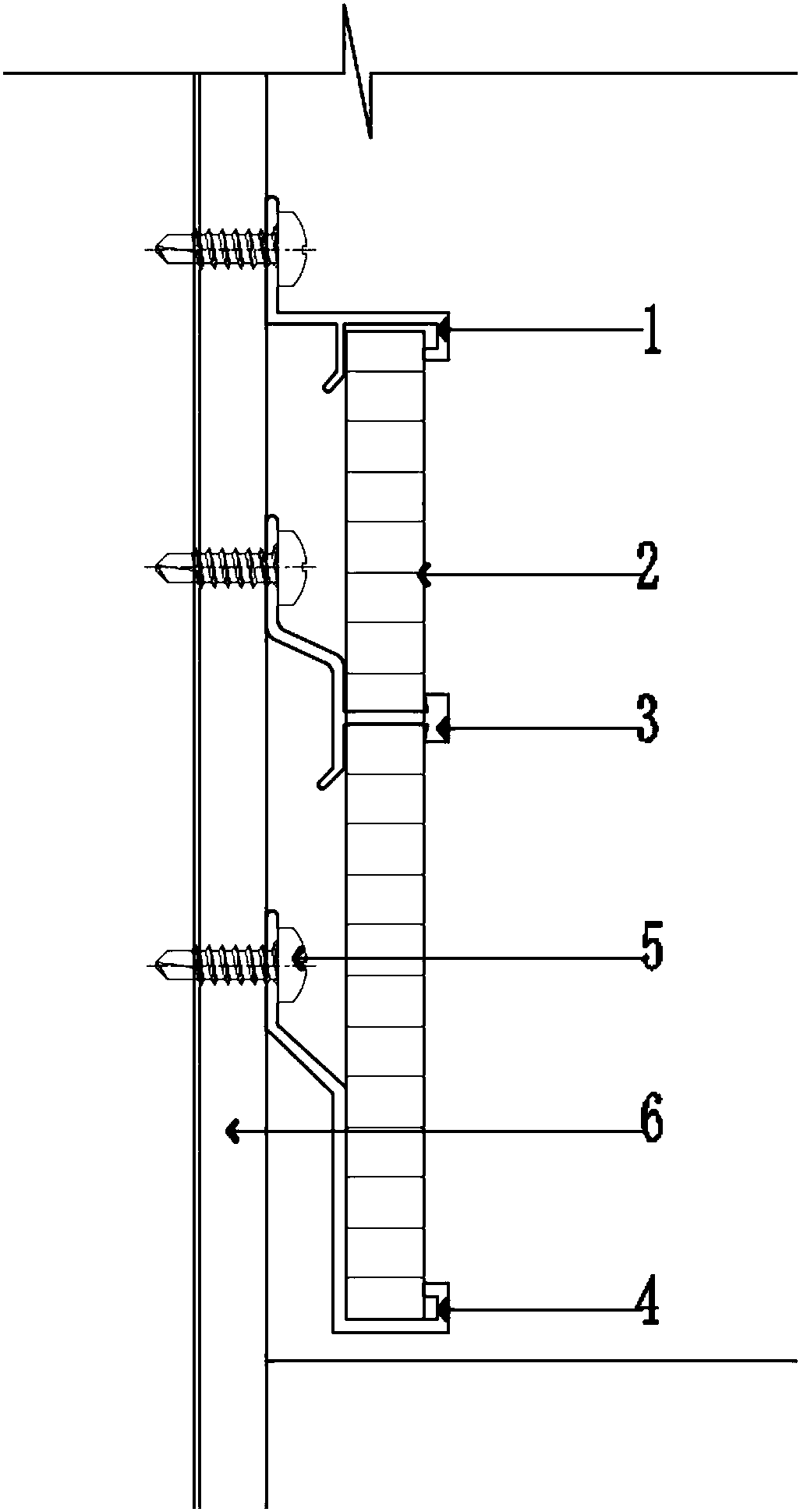

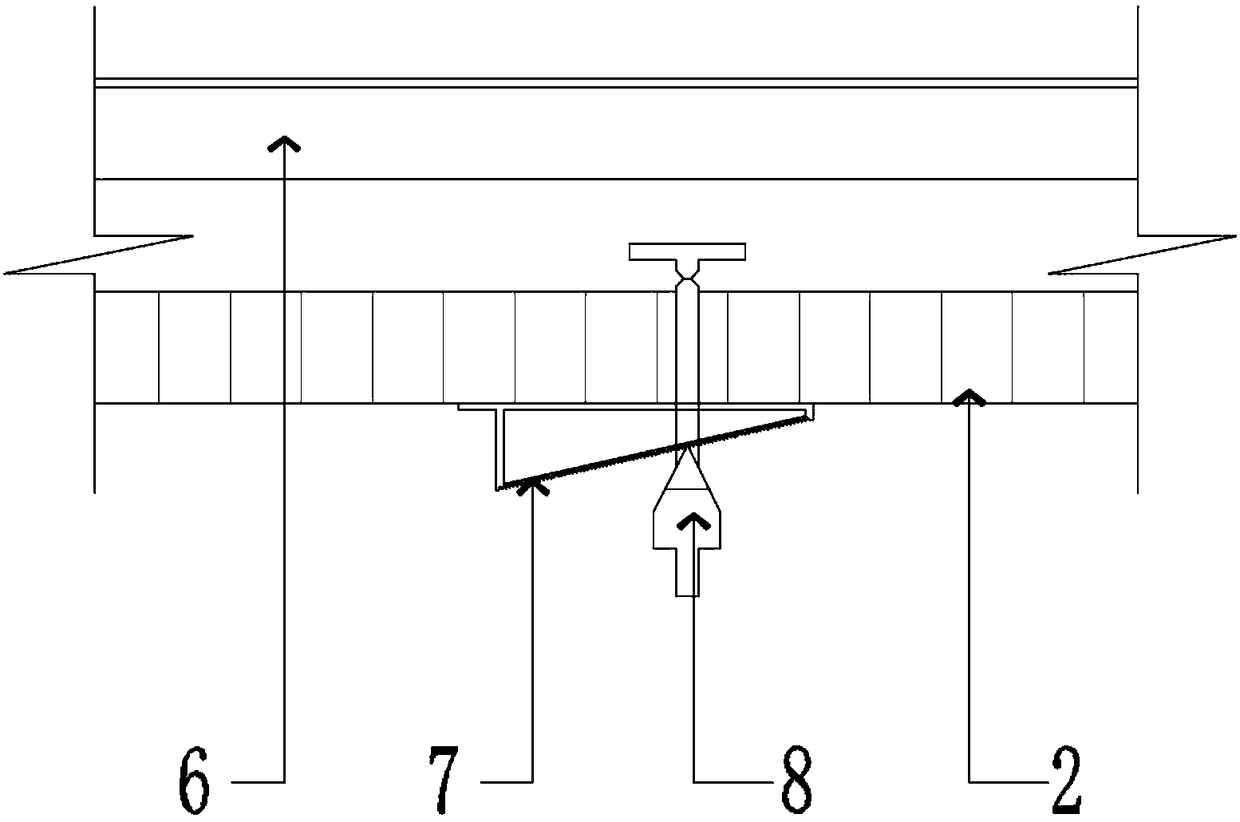

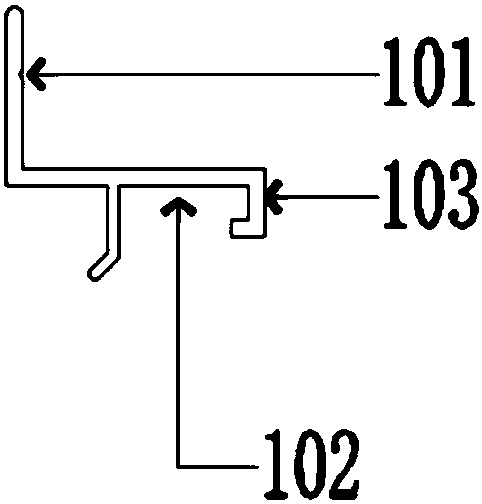

[0052] Such as figure 1 with figure 2 As shown, a prefabricated indoor exposed frame wall brick system includes: top support 1, wall brick 2, middle support 3, bottom support 4, self-tapping screw 5, leveling keel 6, leveler cap 7, pull bar 8 ; The leveling keel 6 is fixed on the solid wall.

[0053] The bottom bracket 4 is detachably connected to the leveling keel 6, and the wall brick 2 is put into the bottom bracket and injected with structural glue; the middle bracket 3 is detachably connected to the leveling joist 6, and the wall brick 2 is snapped into the middle bracket and injected with structural glue ;The pull bar 8 is put into the two vertical wall bricks; the jacking 1 is detachably connected with the leveling keel 6, and the top of the wall brick is snapped into the jacking bracket and injected with structural glue. The wall brick transmits the dead weight of the wall brick to the leveling keel 6 .

[0054] The leveler cap 7 is arranged as a wedge-shaped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com