Self-balancing steel underpinning device

A self-balancing, underpinning column technology, applied in building maintenance, construction, building construction, etc., can solve problems such as construction waste, increased cost of lower shifted tracks, unusable four-sided wrapped underpinning nodes, etc., to achieve The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

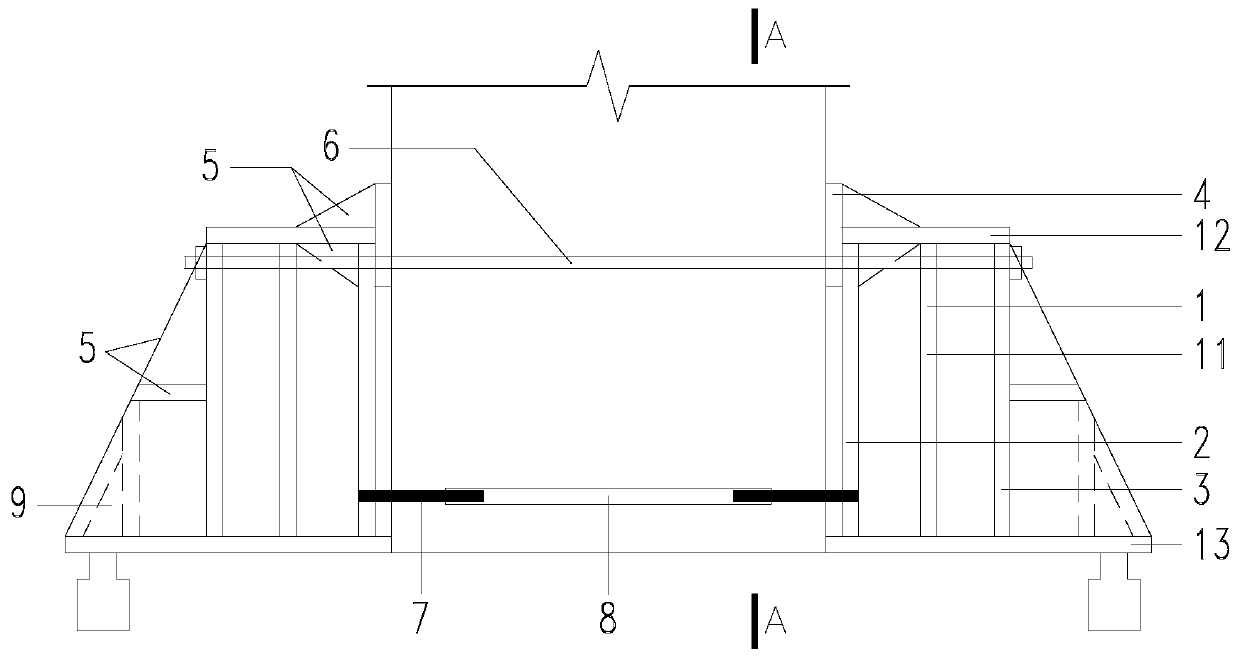

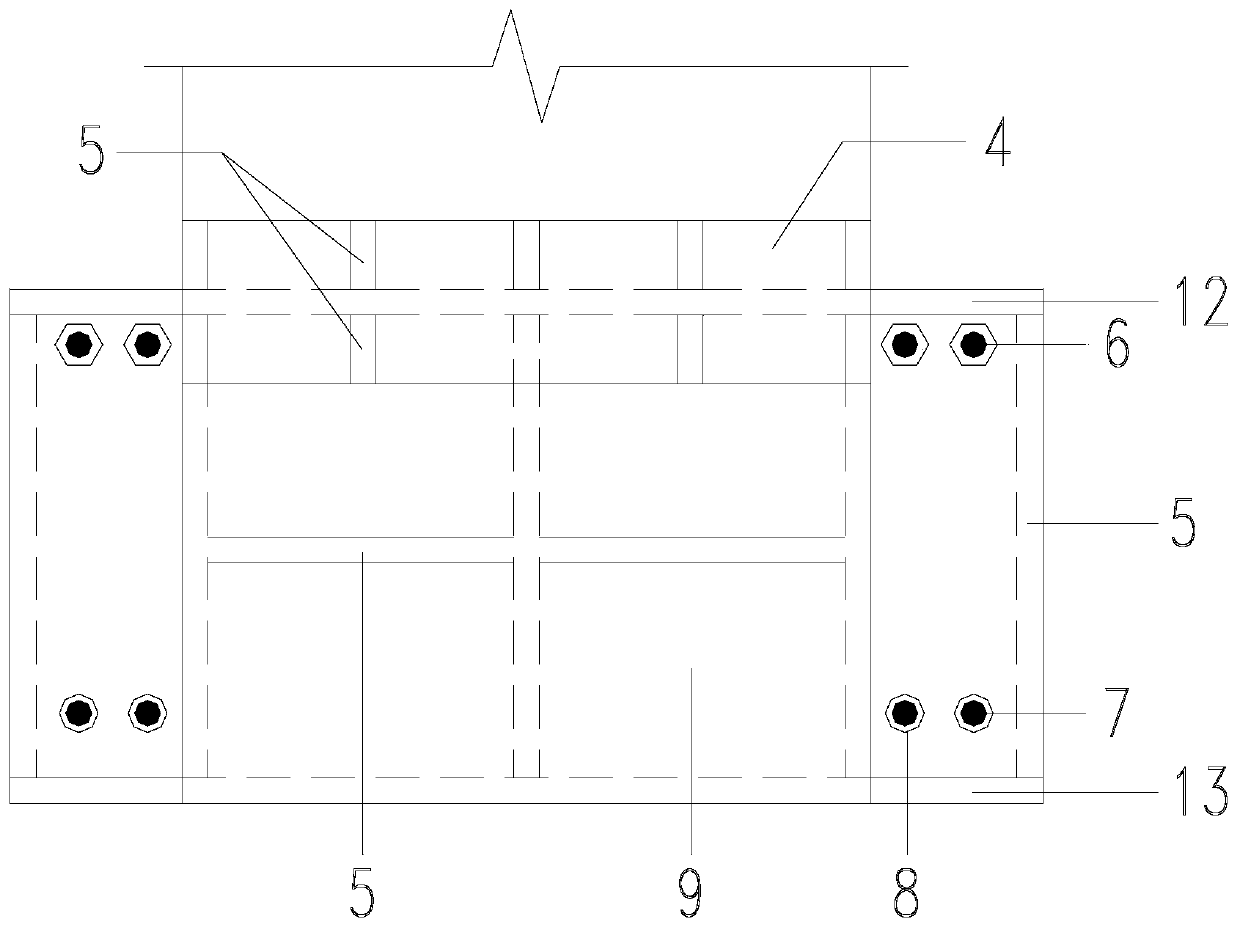

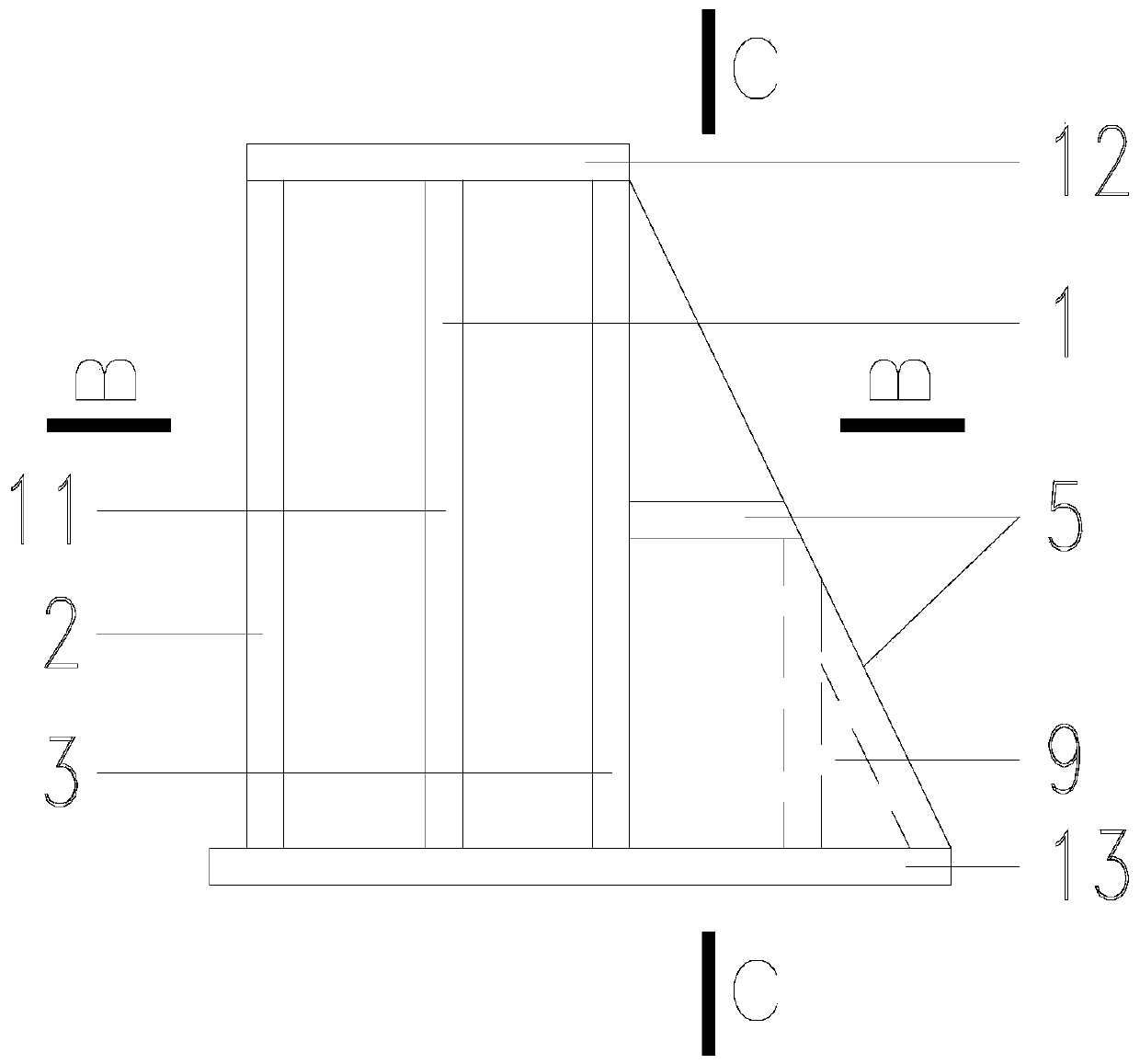

[0052] Such as Figure 1~2 As shown in , a self-balancing steel underpinning device includes two sets of underpinning members arranged symmetrically on both sides of the underpinning column, and a jack arranged under the underpinning members, such as Figure 3-5 As shown, each group of underpinning members includes unequal flange I-shaped steel 1, the first connecting steel plate 2 arranged inside the unequal flange I-shaped steel 1, and the first connecting steel plate 2 arranged outside the unequal flange I-shaped steel 1 The second connecting steel plate 3, the pressure steel plate 4 welded to the upper flange 12 of the unequal flange I-shaped steel, and the stiffener 5 welded to the above-mentioned components. A connecting screw 7 is arranged on one side of the first connecting steel plate 2 , and a pull screw 6 is arranged between the second connecting steel plates 3 .

[0053] The principle of the present invention is: under the action of the underpinning load on the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com