A prefabricated prefabricated column splicing rigid connection node and construction method

A rigid connection and prefabricated column technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of difficult construction and positioning of hoisting components, cumbersome construction operations, poor seismic performance, etc., and achieve the effect of shortening the construction period, reliable connection and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A prefabricated prefabricated column splicing rigid connection node and construction method proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will become apparent from the following description and claims.

[0039] Also, expressions such as "first," "second," etc. are only used for the purpose of distinguishing between multiple configurations, rather than limiting the order among the configurations or other features.

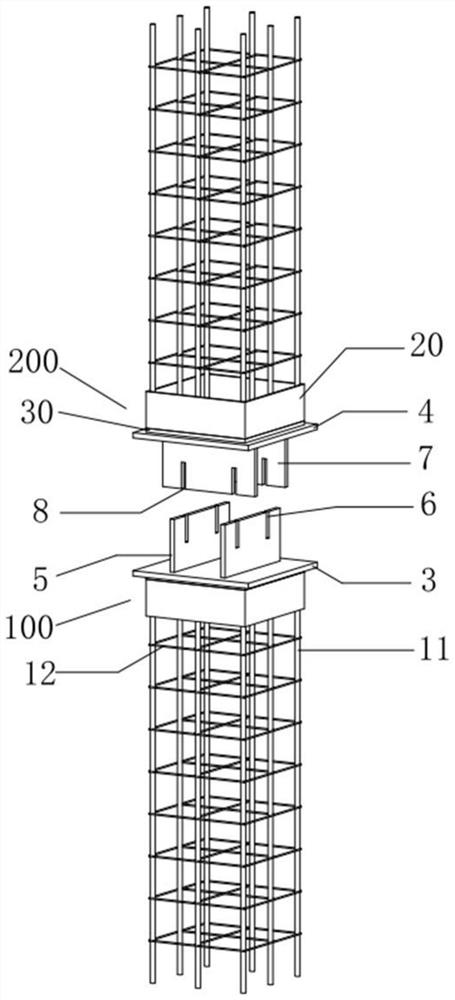

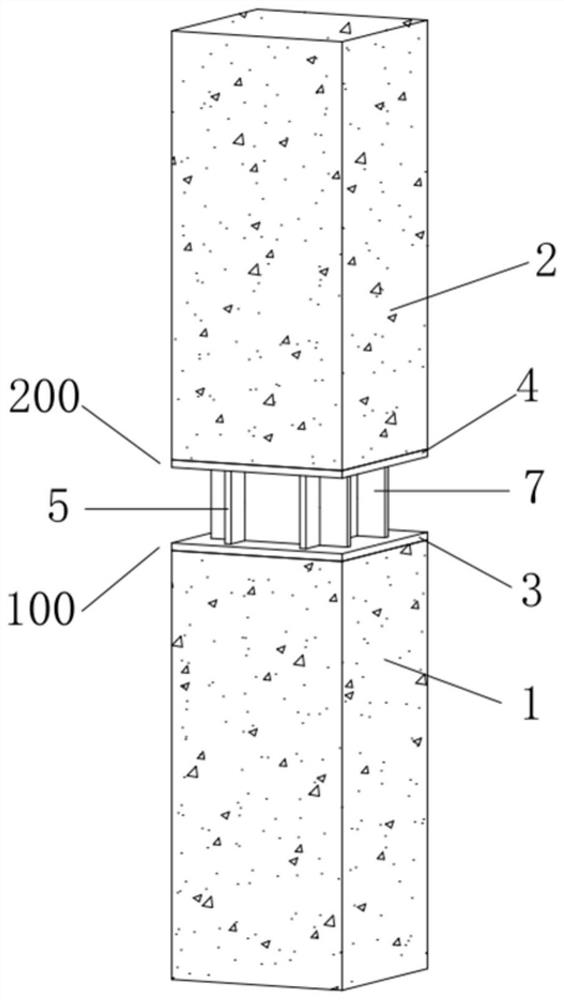

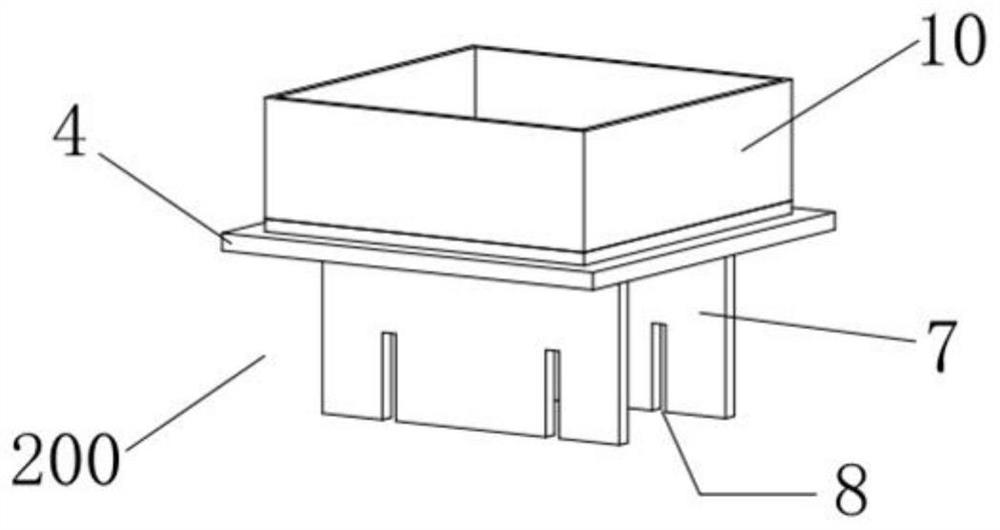

[0040] see Figure 1-Figure 5 , a prefabricated prefabricated column splicing rigid connection node, comprising: an upper prefabricated column 2 and a lower prefabricated column 1, the upper prefabricated column 2 and the lower prefabricated column 1 both contain longitudinal stress steel bars 11 and stirrups 12, and the upper prefabricated column 1 The first connecting device 200 is pre-embedded in the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com