Novel wall bushing and through-wall hole blocking method adopting same

A technology of wall-piercing sleeves and construction methods, which is applied to vertical pipes, building components, building insulation materials, etc., can solve problems that affect project progress and construction costs, cumbersome and complicated processes, and leakage plugging costs, etc., and achieve simple structure, The operation is simple and easy to solve the effect of stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

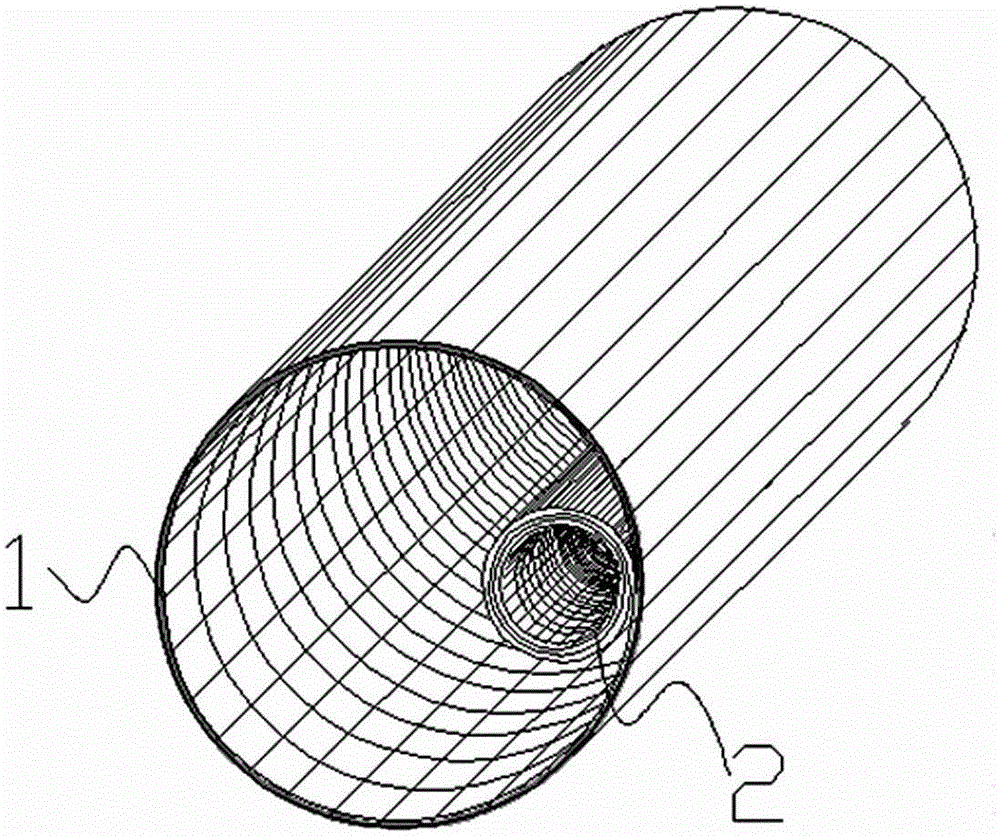

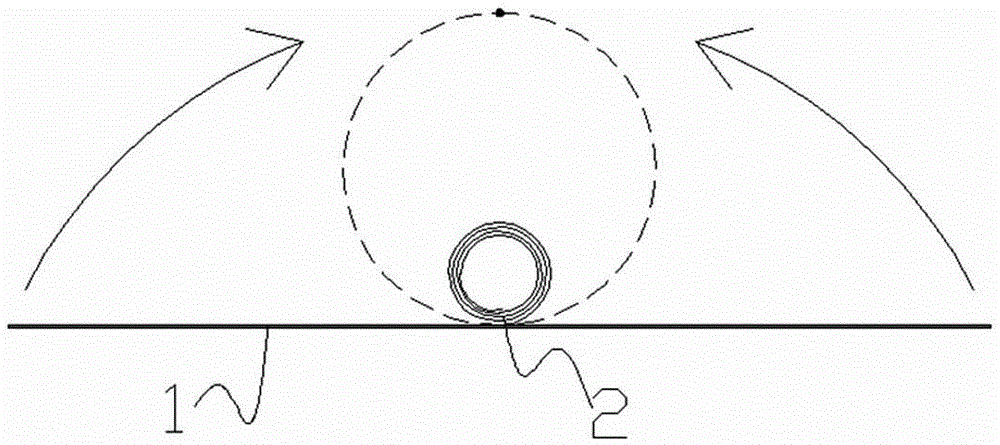

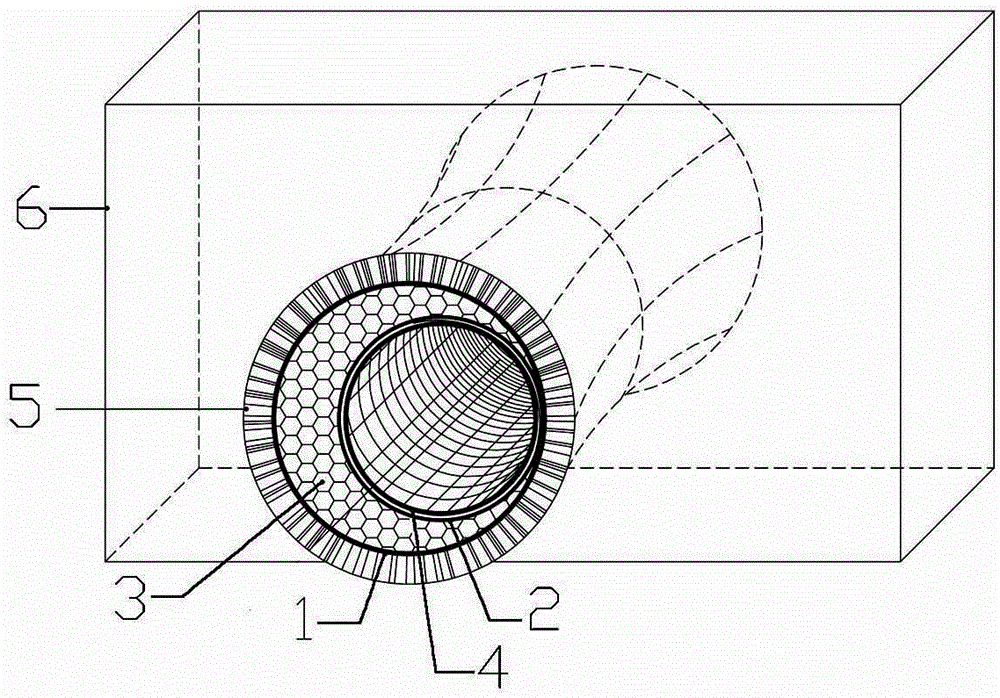

[0032] figure 1 It is a schematic diagram of the production of the new wall-piercing sleeve involved in the present invention, which includes an outer sleeve 1, and a stress metal reel 2 is set inside the sleeve 1; the stress metal reel 2 is a single sheet metal coil The multi-layer reel structure with inward rolling stress is made, the curling outside the multi-layer reel structure is welded on the inner wall of the sleeve 1 for fixing, the central axis of the stress metal reel 2 and the central axis of the sleeve 2 parallel. The sleeve 1 is a single-layer cylindrical structure formed by rolling a rectangular metal plate and welding the ends of both ends. , and the three are welded and fixed together. The diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com