Prefabricated indoor hidden frame type wall brick system and construction method thereof

A construction method and prefabricated technology, applied in covering/lining, architecture, building structure, etc., can solve problems such as the inability to meet the needs of prefabricated building decoration, and achieve solutions such as emptying and falling off of paving, excellent stress performance, etc. The effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

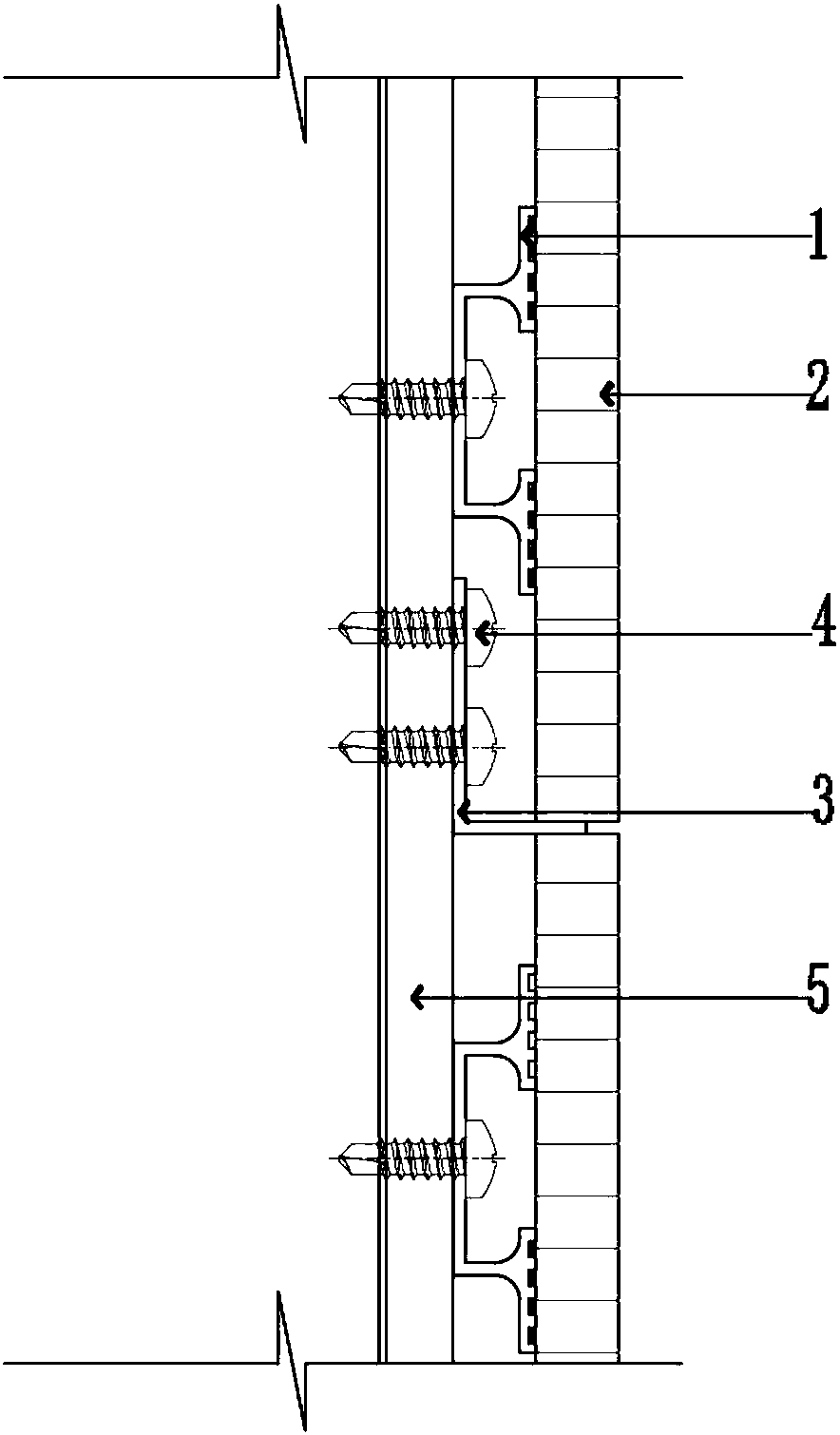

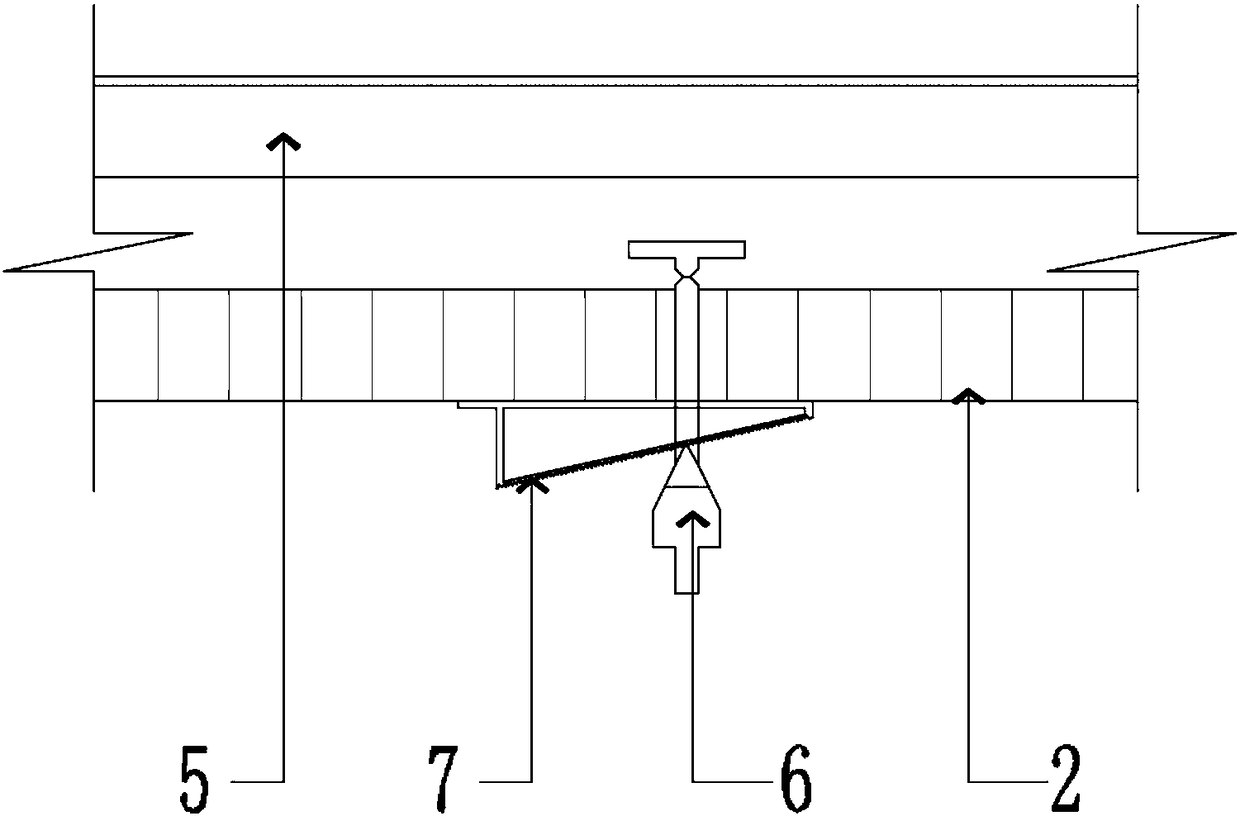

[0047] Such as figure 1 with figure 2 As shown, an assembled indoor hidden frame wall brick system includes: rubber rib 1, wall brick 2, L-shaped corner code 3, self-tapping screw 4, leveling keel 5, brace 6, and leveler cap 7.

[0048] Level the keel and fix it on the solid wall;

[0049] The L-shaped corner code can be detachably connected to the leveling keel and applied with structural glue; the rubber tendon keel can be detachably connected with the leveling keel and applied with structural glue, and the wall tiles are dragged with the L-shaped corner code and then bonded to the rubber tendon keel ; The brace is installed in the two wall tiles of the vertical joint; the leveler cap is set in a wedge-shaped structure, wedged between the vertical seams of the pre-embedded wall brick of the brace, and the brace is tightened.

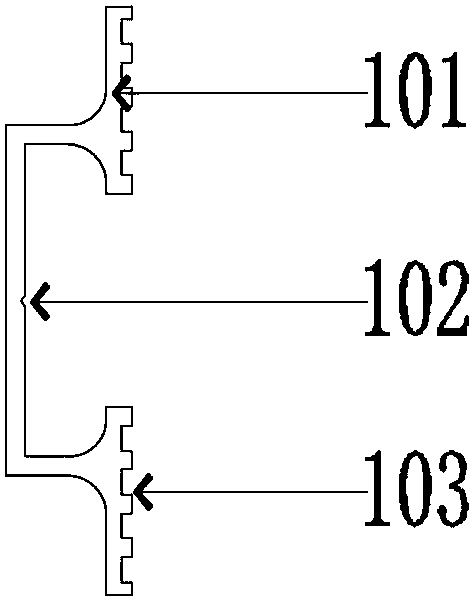

[0050] The shape of the rubber band keel and the L-shaped corner code and the functional design of the notch, see image 3 with Figure 4 .

[0051] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com