Wall body, hanging plate bolting assembly and construction method thereof

A component and hanging board technology, which is applied in the direction of formwork/template/work frame, wall, building components, etc., can solve the problem of lack of a strong connection structure between the wall and the internal and external hanging boards, so as to reduce the construction process and improve the construction. Efficiency, the effect of increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1 Bolted assembly of wall body and hanging board

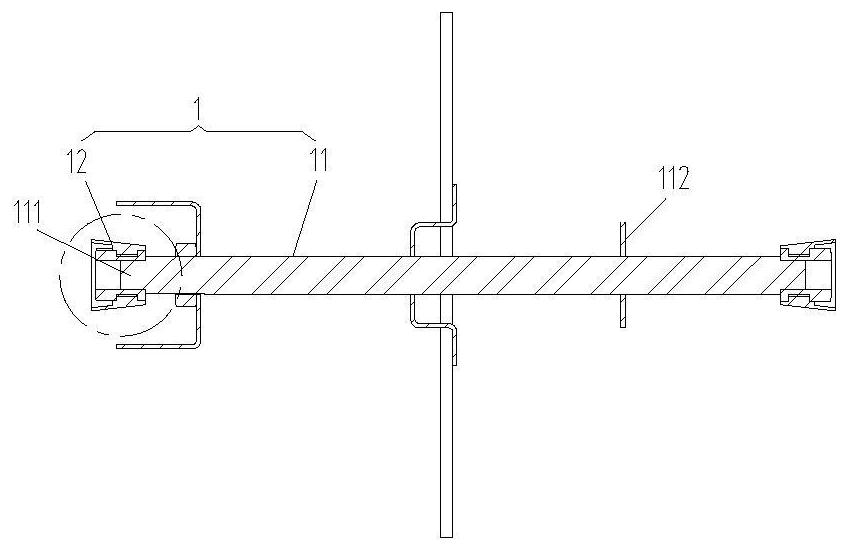

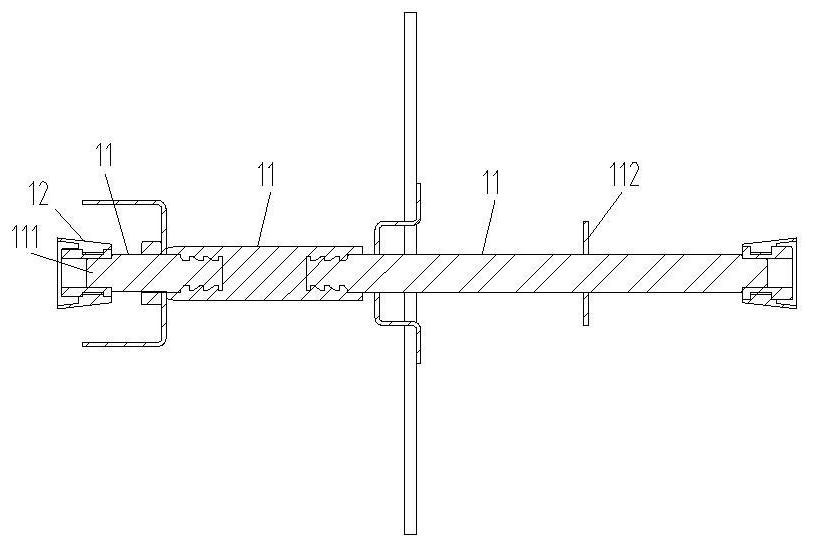

[0097] Such as Figure 1-7 As shown, the bolted assembly of the wall body and the hanging board includes a supporting positioning member 1 , a tie rod 13 , a fixed connecting member 2 and a hooking assembly 3 .

[0098] (1) Support positioning part 1

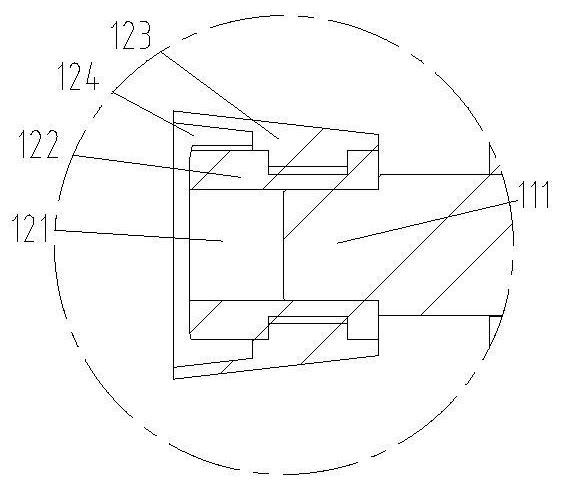

[0099] Such as Figure 1-3 As shown, the support positioning member 1 includes a support member 11 and a positioning cap 12 . The support member 11 is rod-shaped, at least one end of the support member 11 forms a first screw rod 111 , and a threaded hole 121 matching with the first screw rod 111 is provided at the axis of the positioning cap 12 . After the first screw 111 is screwed into the threaded hole 121, the end surface of the first screw 111 is located in the middle of the threaded hole 121, and the positioning cap 12 is cylindrical or tapered from the outer end to the inner end. A block is formed inside the first screw 111 for limiting the maximum s...

Embodiment 2

[0128] Embodiment 2 Bolting system of wall and hanging board

[0129] The wall and hanging board bolting system can be formed by connecting the wall and hanging board bolting components described in Embodiment 1. Specifically, it includes a wall body 5 , a supporting positioning part 1 embedded in the wall body 5 , a fixed connecting part 2 and a hook assembly 3 .

[0130] Wherein, at least one end of the support member 11 extends to the edge of the wall 5 or extends close to the edge of the wall 5 , and this end has a first screw 111 , and the wall 5 around the first screw 111 forms a pit. In this embodiment, the first screw 111 can extend to the middle or the edge of the positioning cap 12, as long as it does not exceed the surface of the wall 5, it belongs to the protection scope of the wall 5 and hanging board 4 bolting system of this patent. The screw sleeve 22 of the fixing connector 2 protrudes into the recess and cooperates with the first screw rod 111 .

[0131] The...

Embodiment 3

[0134] Example 3 Hanging system for hanging boards

[0135] Such as Figure 8-19 As shown, the hanging plate hooking system includes a hanging bracket 31 and at least one hanging plate 4, and also includes a pin hanging assembly 33, and the pin hanging assembly 33 includes:

[0136] A number of first inner hooks 321 connected to the hanger bracket 31, the first inner hanger 321 has a hook 3211 protruding upwards; several second inner hangers 322 connected to the hanger bracket 31 and / or the first crimping piece 323, the second inner hooking piece 322 or the first crimping piece 323 is located above the first inner hanging piece 321, and the second inner hanging piece 322 has an upward protruding The hook 3211 of the first crimping member 323 has a crimping hook 3231 protruding downward;

[0137] The first external hook 324 is fixed under the inner side of the hanging plate 4, and the external hook has a hanging groove 3241 matched with the hook 3211;

[0138] The second ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com