Method and device for automatic cargo loading

An automatic and cargo technology, applied in the field of loading machinery and conveying, can solve the problems of high labor intensity, inaccurate stacking position, and the impact of dust on the vacuum system, and achieve the effect of large working range and simple system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

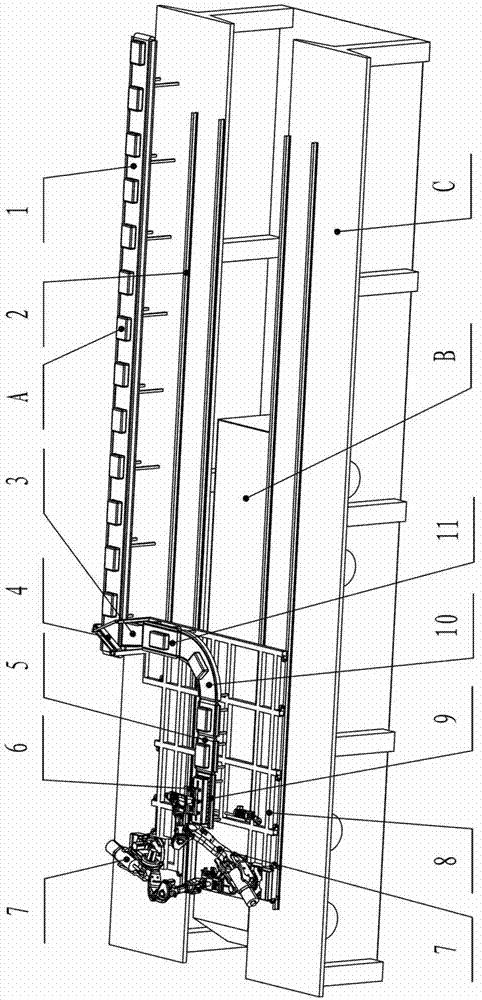

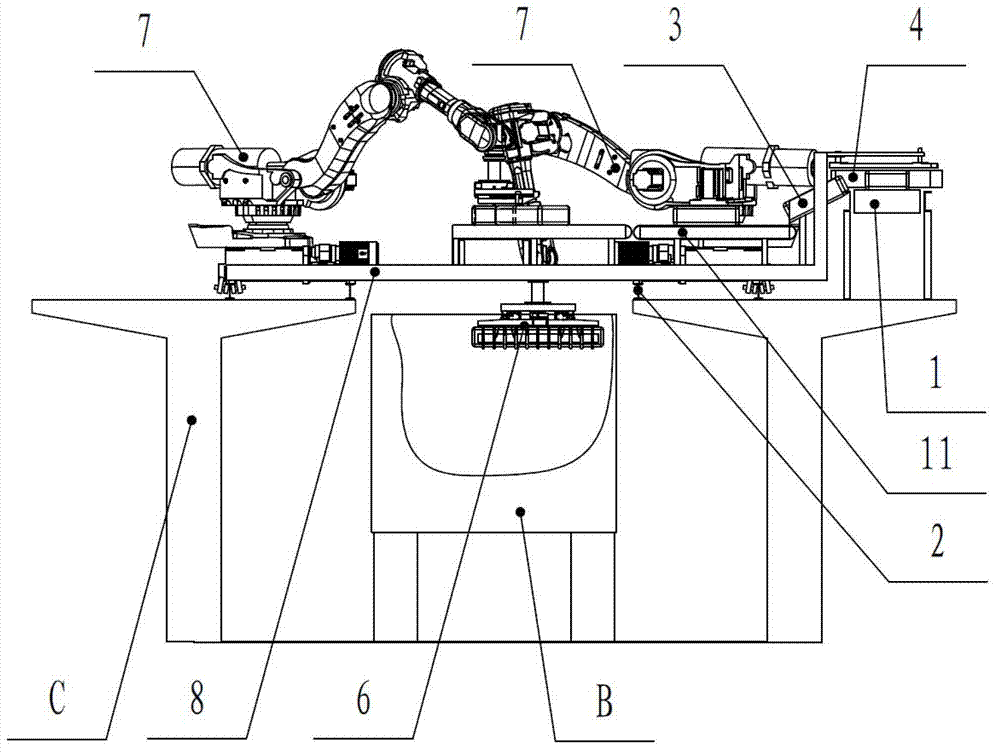

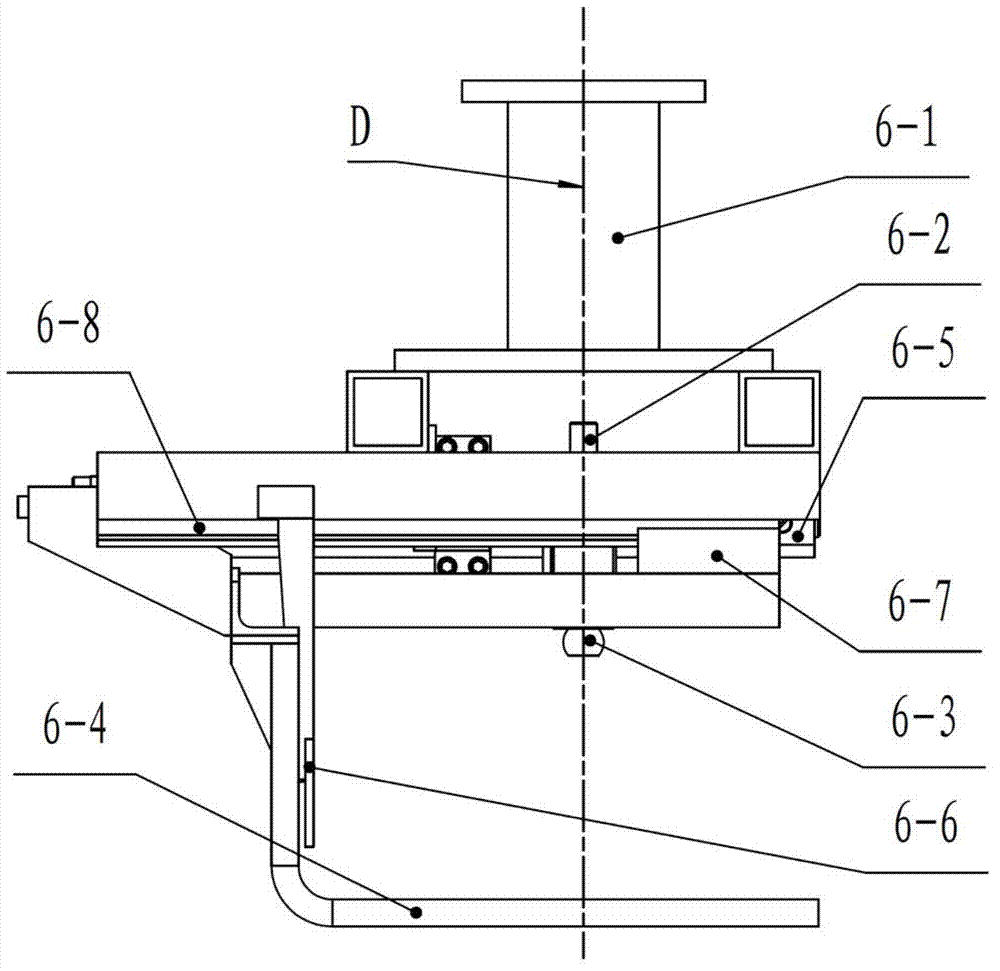

[0027] The specific embodiment of the present invention sees Figure 1 to Figure 7 , for different size of item (A) and width of compartment (B), different grouping and stacking methods can be adopted, assuming that the size of item (A) is 600mm (length) * 400mm (width), compartment (B) The width dimension is 2200mm, then a kind of embodiment of the present invention is as follows:

[0028] A method for automatic loading of goods, which comprises the following process steps:

[0029] (1) Compartment positioning: After the empty vehicle arrives at the designated position in the loading area, the robot (7) detects and locates the front and rear positions, left and right positions of the compartment (B);

[0030] (2) Longitudinal conveying: the long conveyor (1) whose conveying direction is consistent with the length direction of the compartment (B) conveys the article (A) forward;

[0031] (3), horizontal off-line: use the off-line mechanism (4) to make the article (A) leave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com