Clamp for longitudinal beam of rear floor slab of automobile

A rear floor and longitudinal beam technology, which is applied in the field of automobile rear floor longitudinal beam fixtures, can solve problems such as difficulty in guaranteeing consistency, and achieve the effects of ensuring accuracy, ensuring consistency and facilitating promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

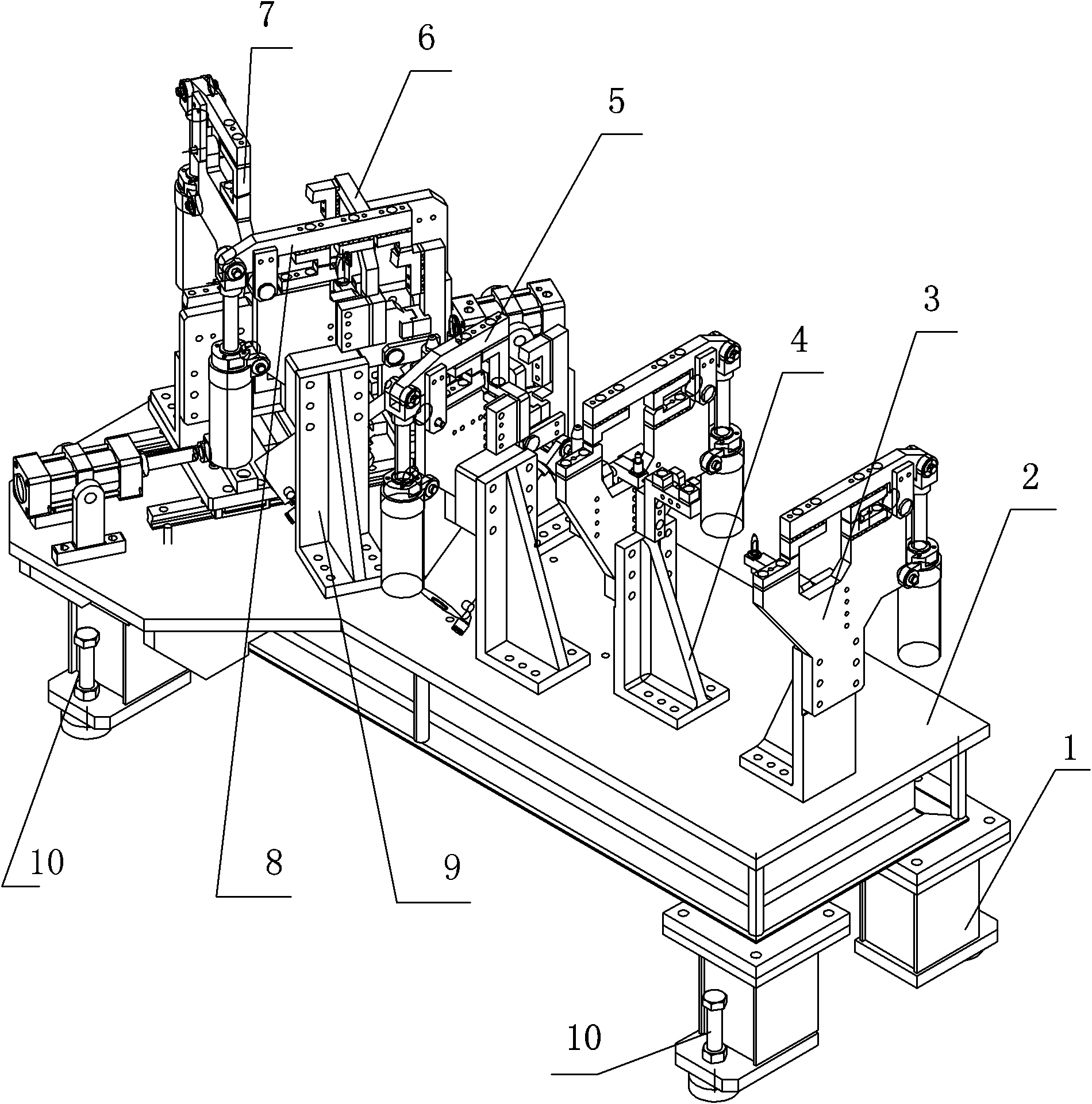

[0044] see figure 1 , the present invention is an automobile rear floor longitudinal beam clamp, comprising a support foot 1, a support platform 2 supported by four support feet 1, and a first positioning clamping device 7, a sliding clamping device 7, a sliding clamping Device 6 , second positioning and clamping device 8 , positioning device 9 , third positioning and clamping device 5 , fourth positioning and clamping device 4 , and fifth positioning and clamping device 3 . Also be provided with adjusting bolt 10 on support foot 1, it can adjust fixture to the working position that suits most employee.

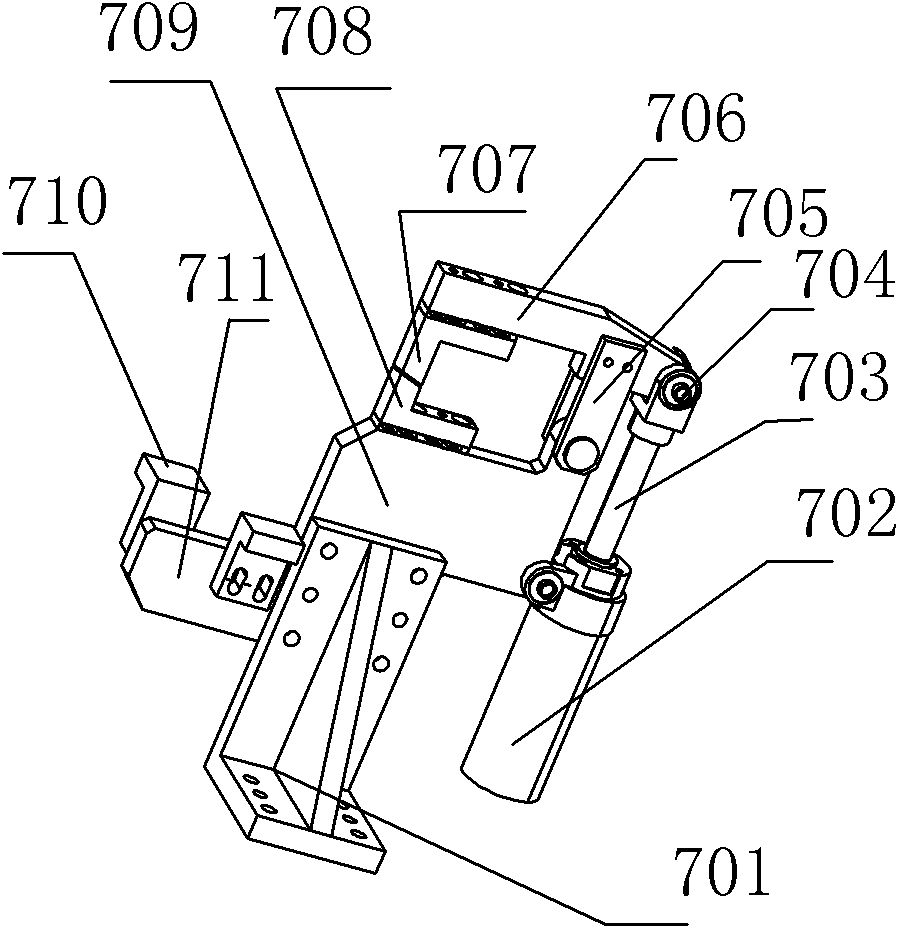

[0045] see figure 2 , figure 2 for figure 1 The first positioning and clamping device 7 of the shown rear floor longitudinal beam clamp includes a corner seat 701 arranged on the support platform 2, a pattern plate 709 fixedly connected to the top of the corner seat 701, and a clamping arm rotatably matched with the pattern plate 709 706 , the clamping block 707 for cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com