Mixed steel-concrete composite frame structure

A frame system and concrete technology, applied in the direction of architecture and building structure, can solve the problems of improving the bearing capacity, increasing the cost of fireproof coatings, and the inability of fireproof coatings to withstand external forces, so as to improve the fire resistance, superior fire resistance and seismic performance of the structure. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

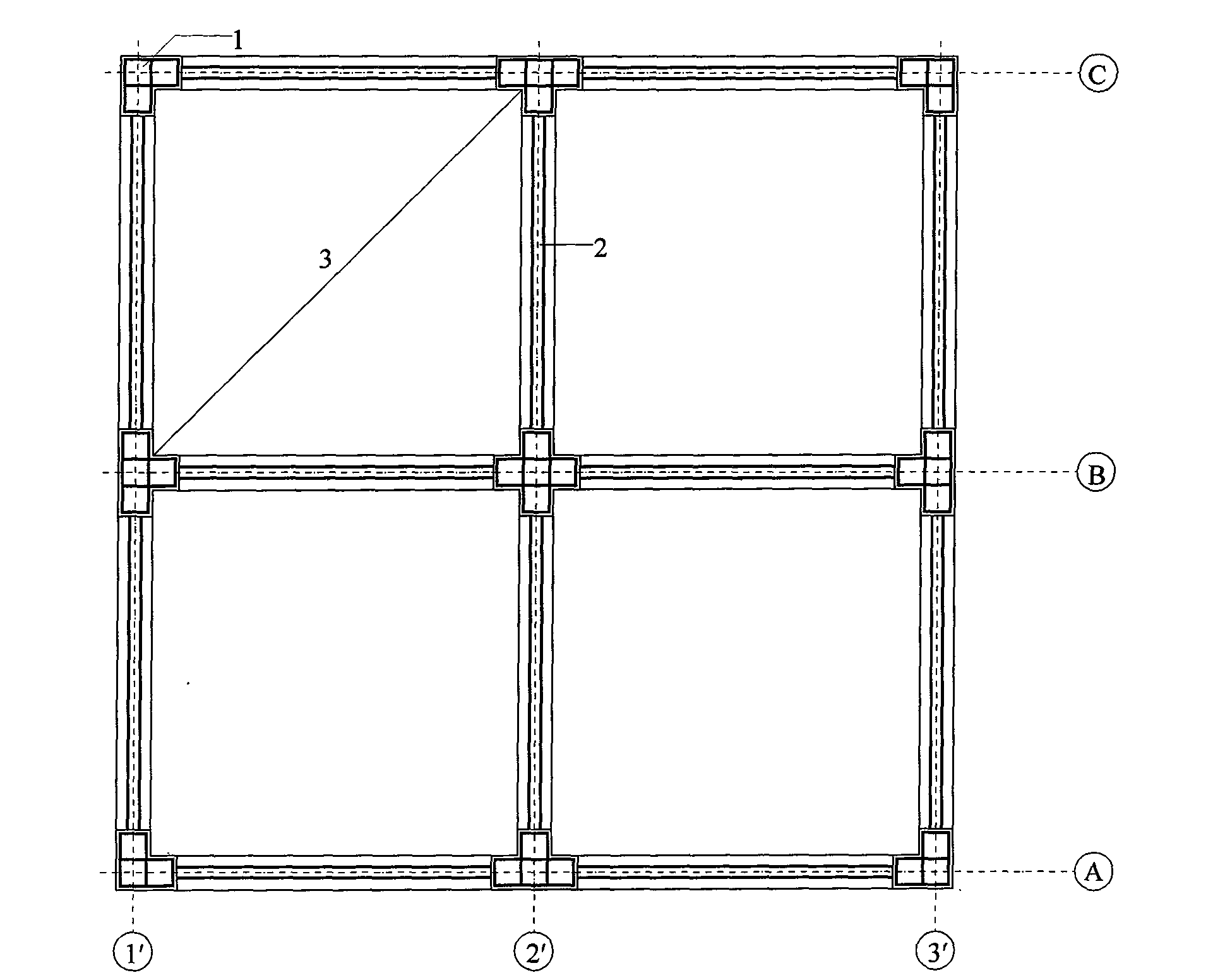

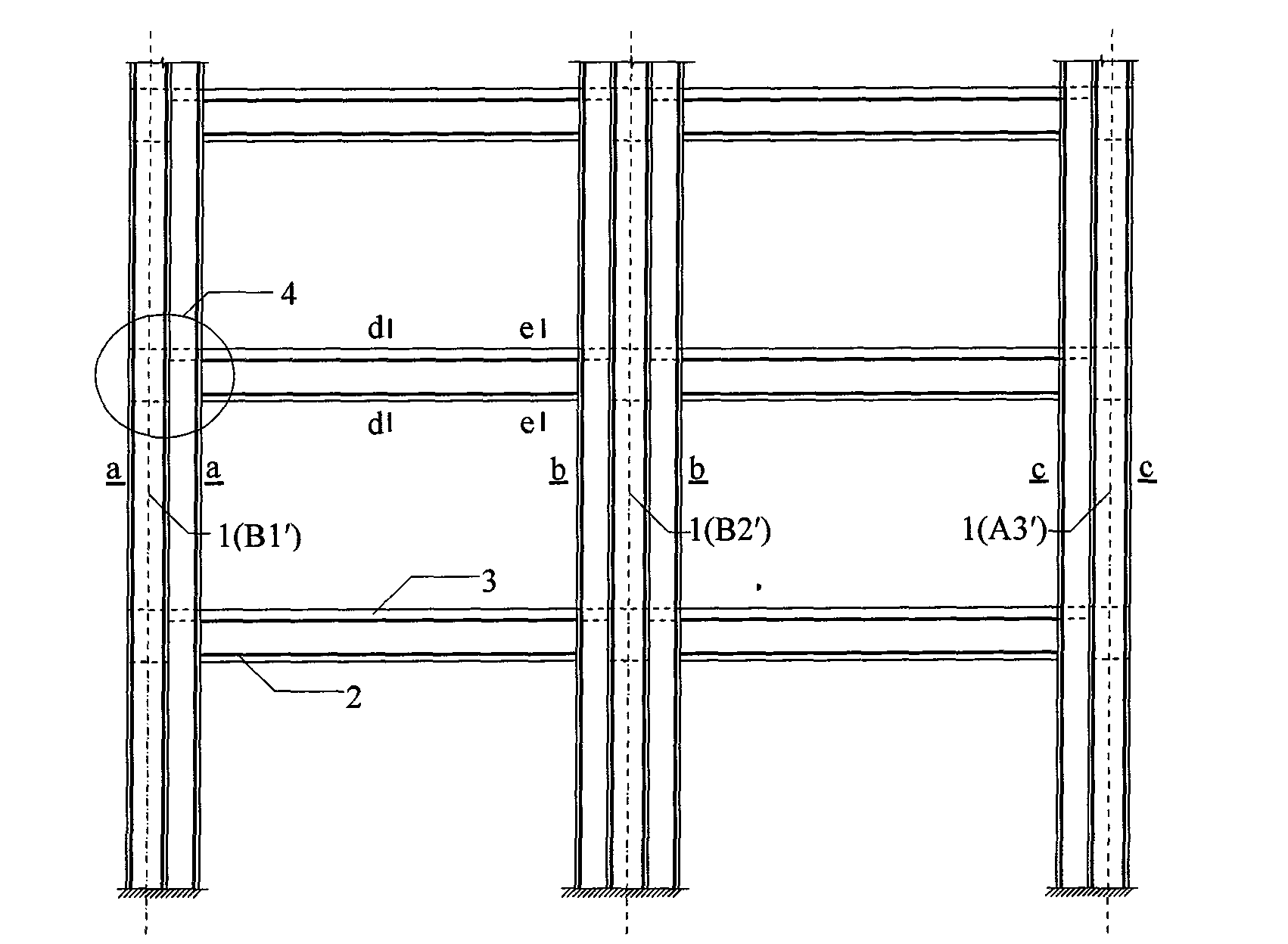

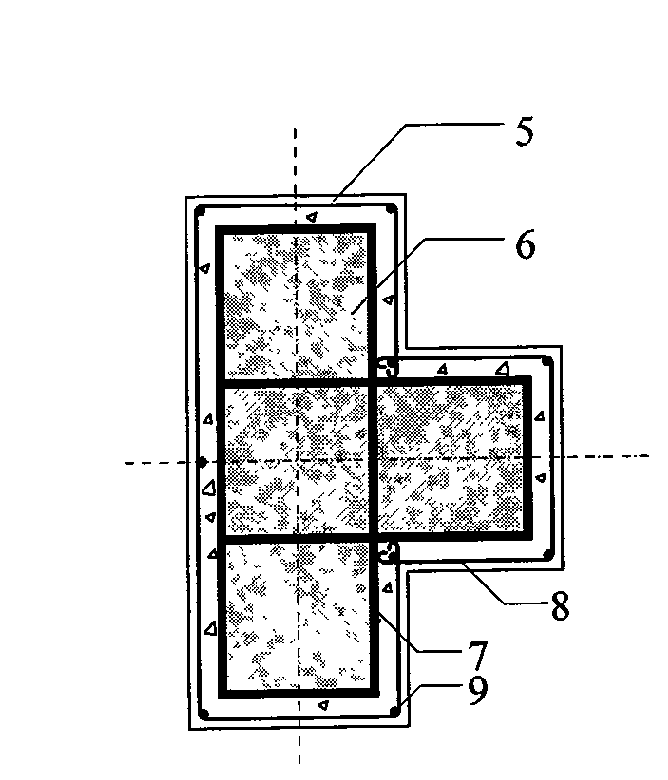

[0022] A hybrid steel-concrete composite frame system, the plan and elevation diagrams of the hybrid steel-concrete composite frame system are as follows figure 1 and figure 2 As shown, the hybrid steel-concrete composite frame system consists of a rigid special-shaped steel pipe concrete composite column 1, a concrete-steel pipe partially filled lightweight aggregate concrete composite beam 2 and a reinforced concrete floor 3; the rigid special-shaped steel pipe concrete composite column 1. When it is a corner column, the section form is "L"; when it is a side column, the section form is "T"; when it is a center column, the section form is "ten"; Sectional view (a-a) of column (column number: B1'), section view (b-b) of center column (column number: B2') and section view of corner column (column number: A3' or C3') (c-c) respectively as image 3 , Figure 4 and Figure 5 As shown; the rigid special-shaped steel pipe concrete composite column 1 has a built-in special-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com