Electric heating press-fit device capable of local temperature control and pressure control

A technology of pressing devices and electric heating devices, which is applied to circuits, presses, fuel cells, etc., to achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above-mentioned purpose, features and advantages of the present invention more comprehensible, preferred implementation modes are specifically cited below, together with the accompanying drawings, and described in detail as follows. However, the following preferred embodiments and drawings are only for reference and illustration, and are not intended to limit the present invention.

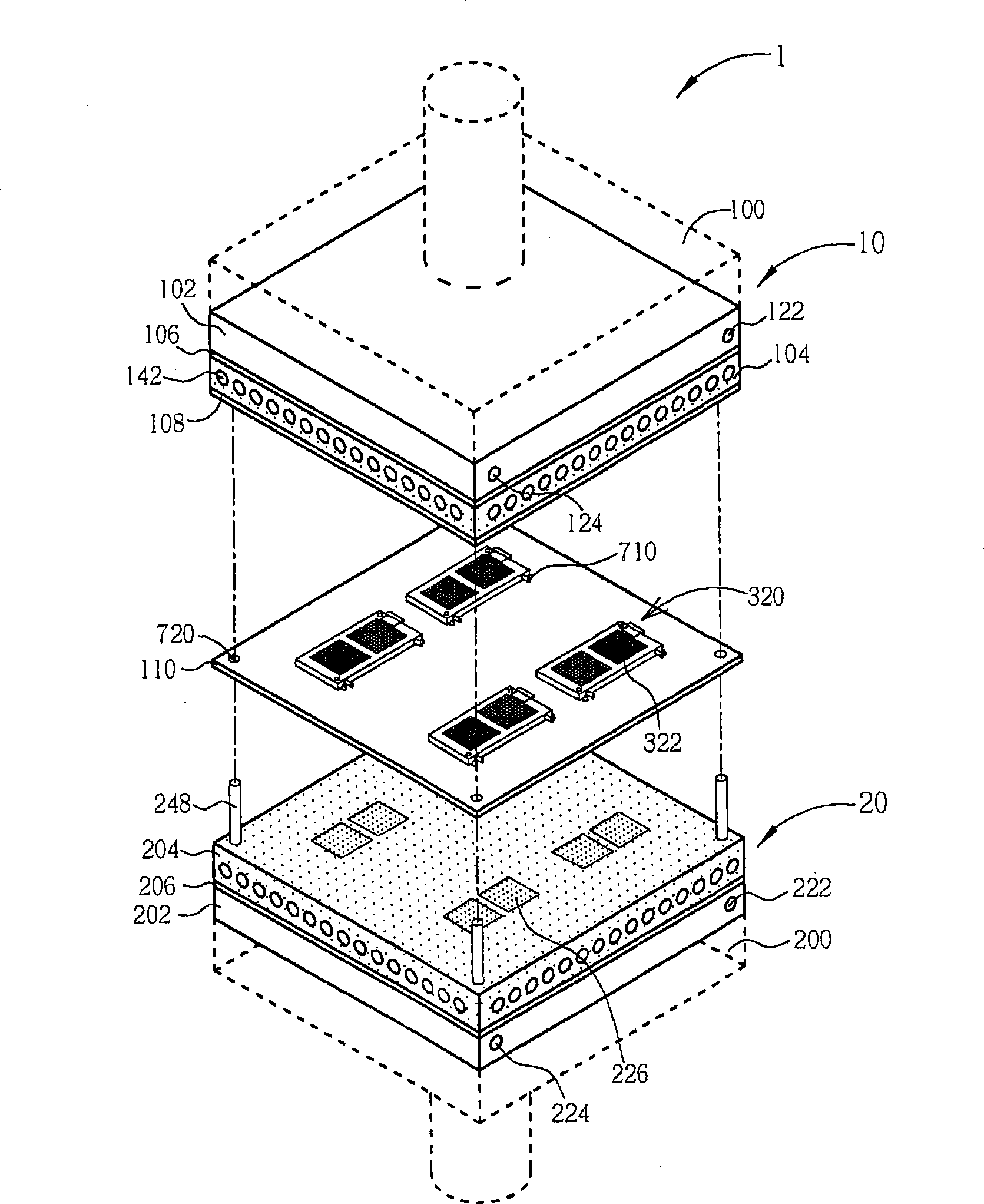

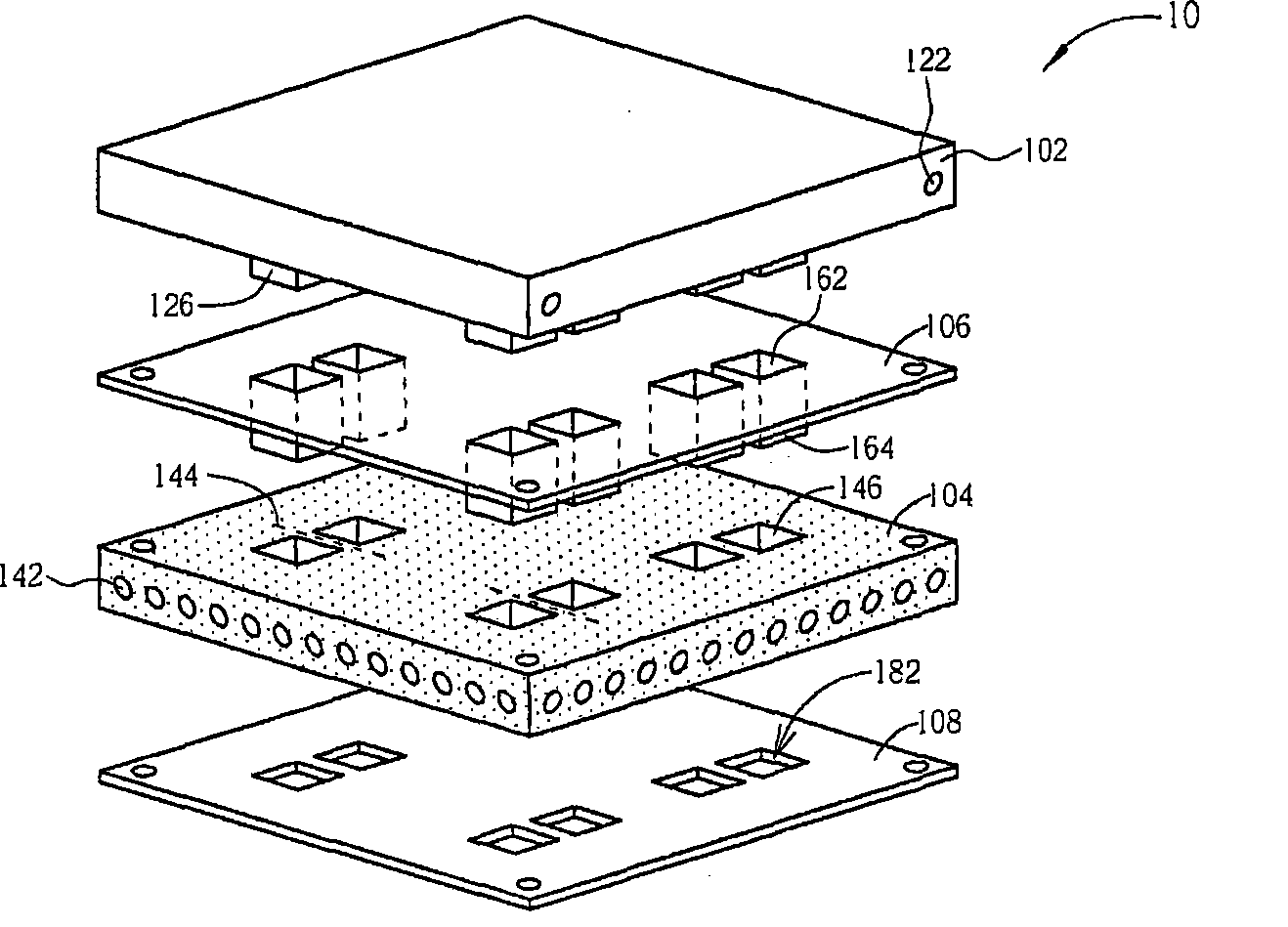

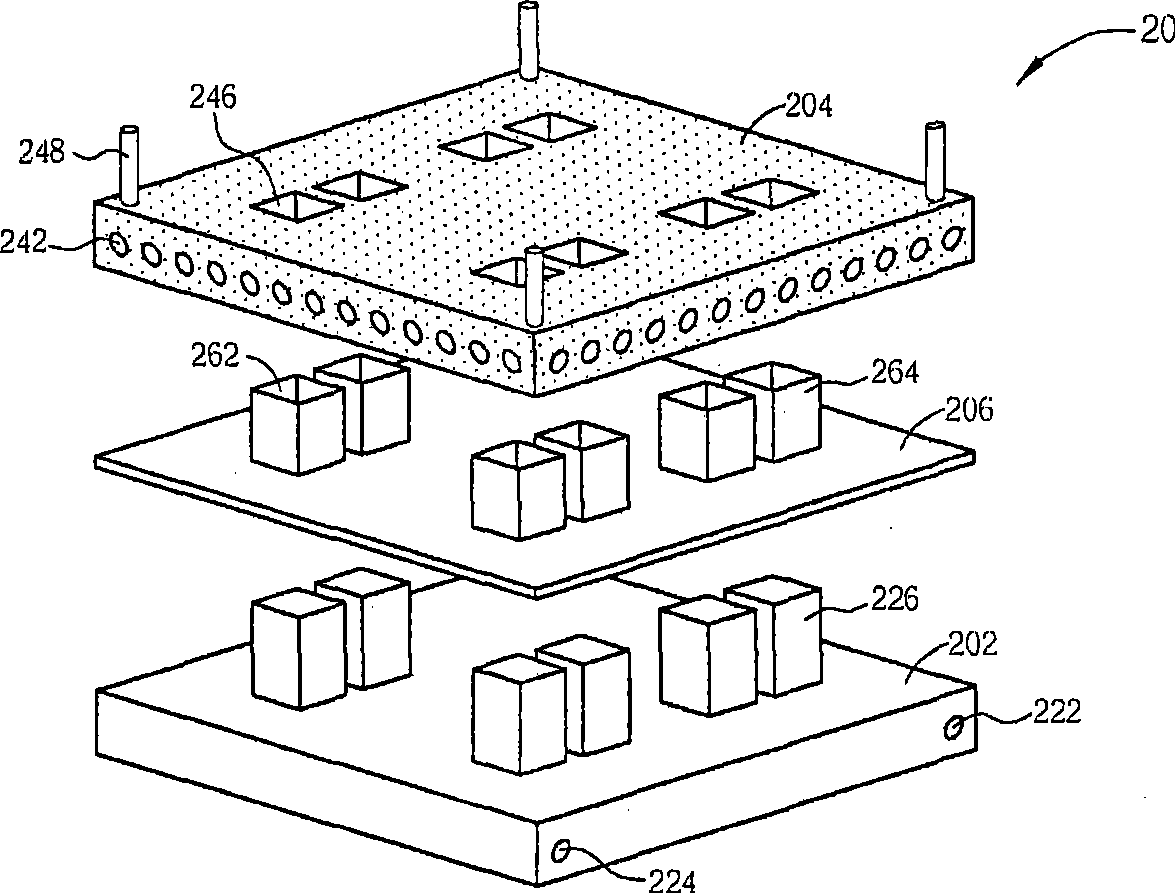

[0037] see Figure 1 to Figure 3 ,in figure 1 It is a three-dimensional exploded view of an electrothermal pressing device 1 according to a preferred embodiment of the present invention, figure 2 is figure 1 The three-dimensional exploded view of the upper jig 10 of the electric thermocompression device 1, image 3 is figure 1 An exploded perspective view of the lower jig 20 of the medium electric thermal pressing device 1 .

[0038] Such as Figure 1 to Figure 3 As shown, the electrothermal pressing device 1 of the present invention includes an upper fixture 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com