Cap head pressing device

A capping head and capping technology, which is applied in the direction of packaging, transportation and packaging, bottle/container caps, etc., can solve the problems of affecting the quality and speed of capping, increasing the cost of compressed air, and the cap cannot be adsorbed, so as to improve the pressure. Cap stability and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

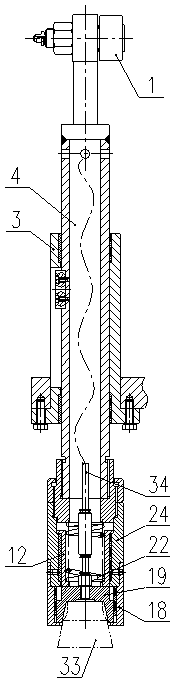

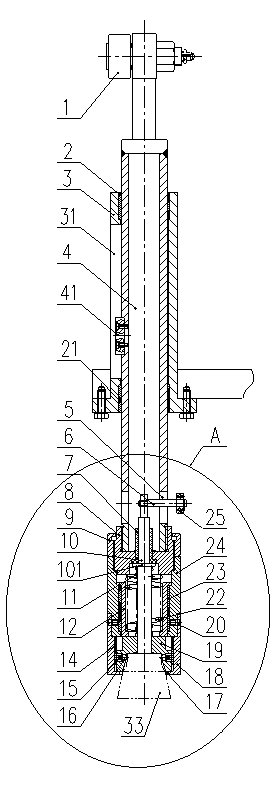

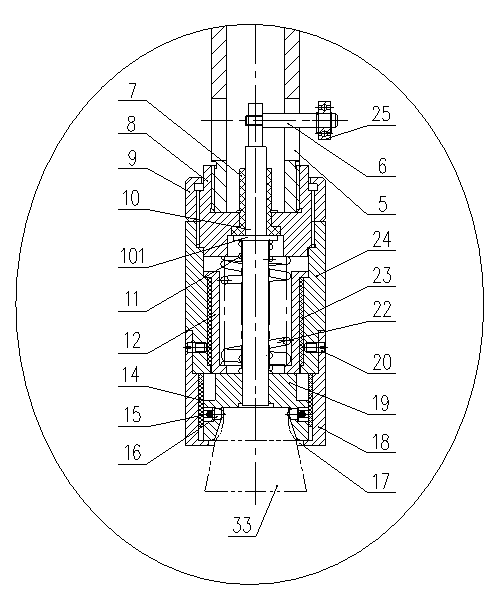

[0021] The capping head device of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0022] see figure 2 , image 3 , Figure 4 As shown, the capping head device of the present invention includes: a lift shaft 4 movably arranged in the guide seat 3, a guide keyway 31 is arranged axially on the side wall of the guide seat 3, and a guide keyway 31 is installed on the lift shaft 4. Key 41, the guide key 41 is arranged in the guide key groove 31, through the cooperation of the guide key 41 and the guide key groove 31, the lifting shaft 4 and the guide seat 3 are locked in the circumferential direction and can slide mutually in the axial direction, and the upper end of the lifting shaft 4 is equipped with a roller 1. The lower end of the lifting shaft 4 is fixedly connected with a connecting block 8, and the connecting block 8 is fixedly connected with a gland seat 24—in this embodiment, the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com