Tri-cone-head pressing grooving plate and grouting slot construction method

A technology of trough formation and pressure, applied in sea area engineering, water conservancy engineering, infrastructure engineering, etc., can solve problems such as difficult to ensure anti-seepage system, and achieve the effect of fast construction, small disturbance of dams, and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

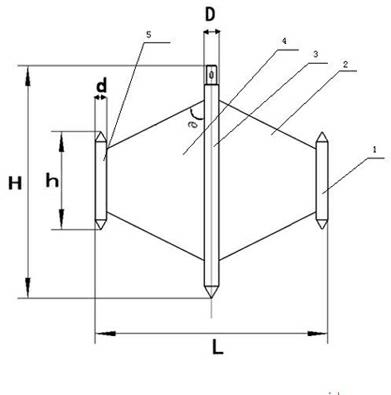

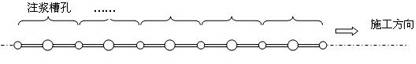

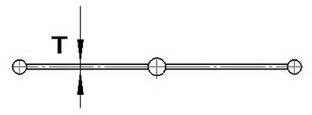

[0023] Such as figure 1 and figure 2 As shown, the three-cone pressure trough plate includes the middle drill pipe 3, the left drill pipe 5 and the right drill pipe 1. The lower end of the rod is a conical head, and the upper end has a connecting head, which can be connected to the static pressing equipment. The shape and size of the left drill rod 5 and the right drill rod 1 are the same, and they are both cylindrical. The left drill rod and the right drill rod Both ends are tapered, the diameter d of the left and right drill pipes is 30~40mm, and the height h is 400~600mm. The left drill rod 5 is connected with the middle drill rod 3 through the left wing plate 4, and the right drill rod 1 is connected with the middle drill rod 3 through the right wing plate 2. The equilateral trapezoidal steel plate with a cutting edge at the end has a thickness of T=10~30mm, and the angle between the trapezoidal hypotenuse and the bottom edge, which is the middle drill pipe, is α=60~70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com