Functionally graded cemented carbide with engineered hard surface and the method for making the same

一种硬质合金、功能梯度的技术,应用在结合耐磨性及韧性的功能梯度硬质合金领域,能够解决功能梯度硬质合金制备困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention relates to a surface-hardened functionally graded cemented carbide and a preparation method thereof. The cemented carbide is prepared by liquid phase sintering and the liquid phase sintering can be an existing standard method. These standard methods include, for example: preparing tungsten carbide - Cobalt (WC-Co) powder which is a mixture of powders of tungsten carbide, tungsten, carbon and cobalt, and pressing these powders together. In other embodiments, these powders can be pressed using some known techniques, such as uniaxial cold pressing.

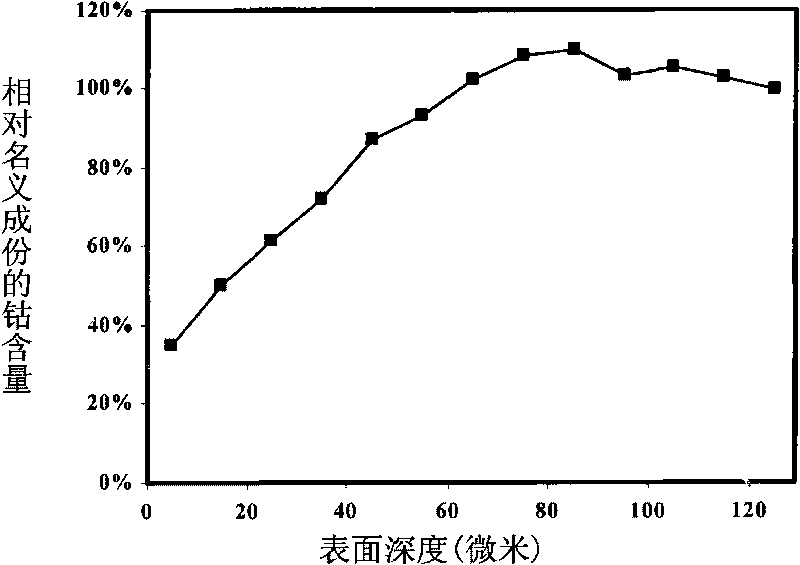

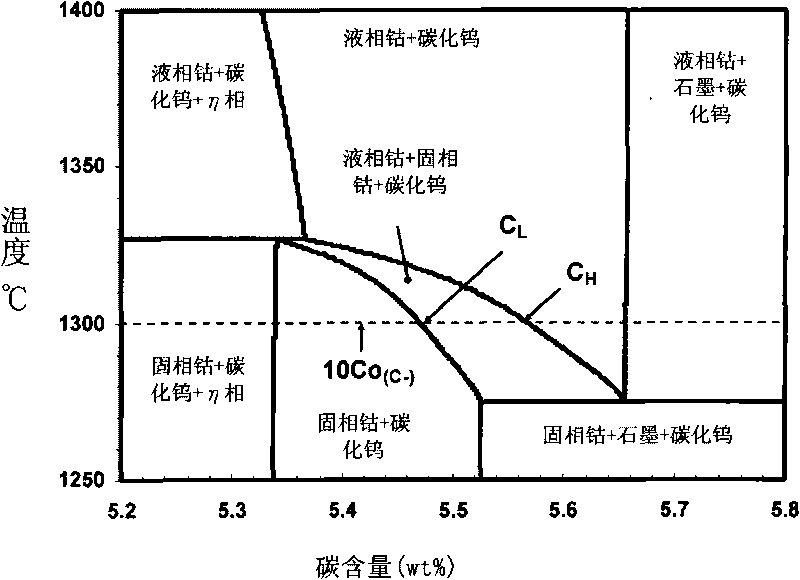

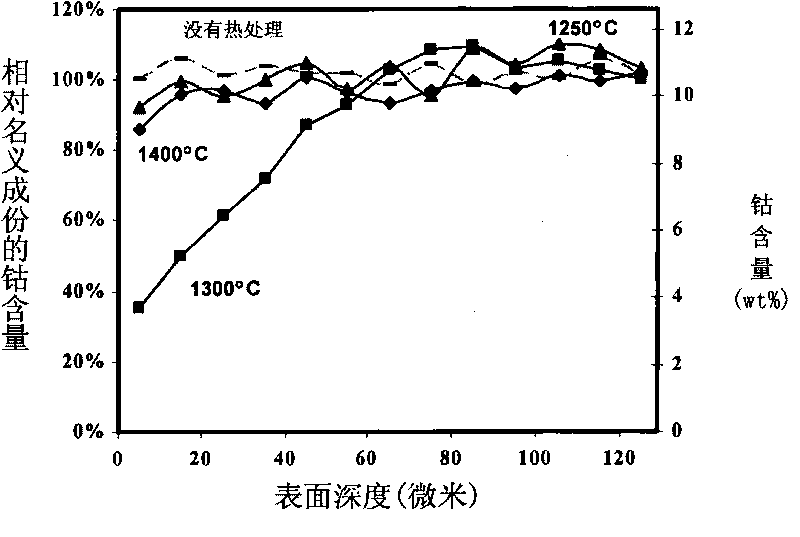

[0034] After the powder is compacted, the powder can be sintered using some standard sintering process, such as maintaining a temperature of 1400°C in a vacuum. The existing sintering process can produce a uniform cemented carbide, that is, the amount of cobalt in the tungsten carbide (WC) matrix is uniformly distributed throughout the sample. However, in this embodiment, in addition to the aforementio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com