Laser near-net shaping method for metal-ceramic multi-dimensional functionally-graded structural component

A laser near-net-shaping and functional gradient technology, applied in the field of laser near-net-shaping, can solve the problems of inability to directly form complex structural parts, single functional gradient change dimension, etc., and achieve rich material design options, continuous change, and strong processing flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

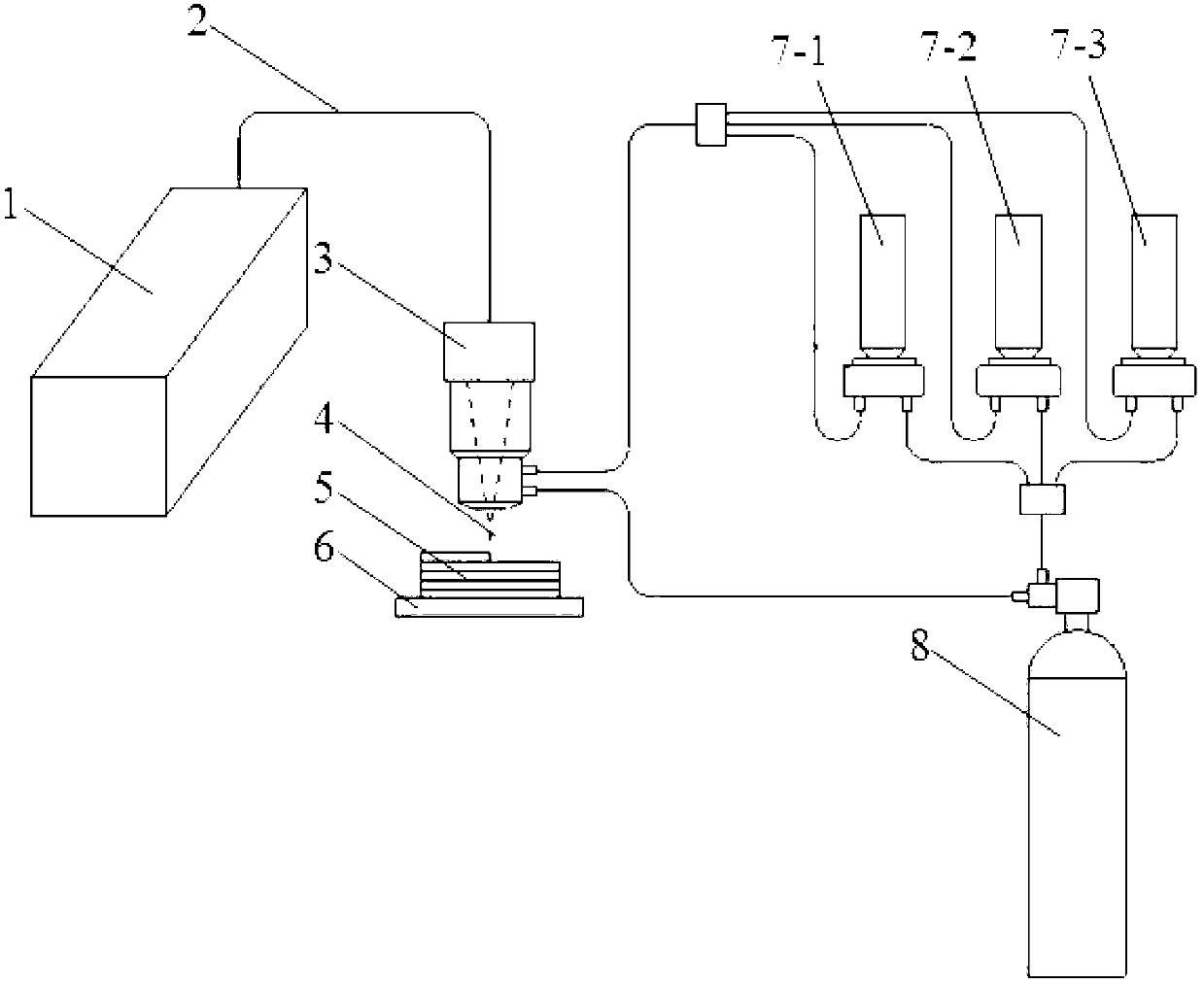

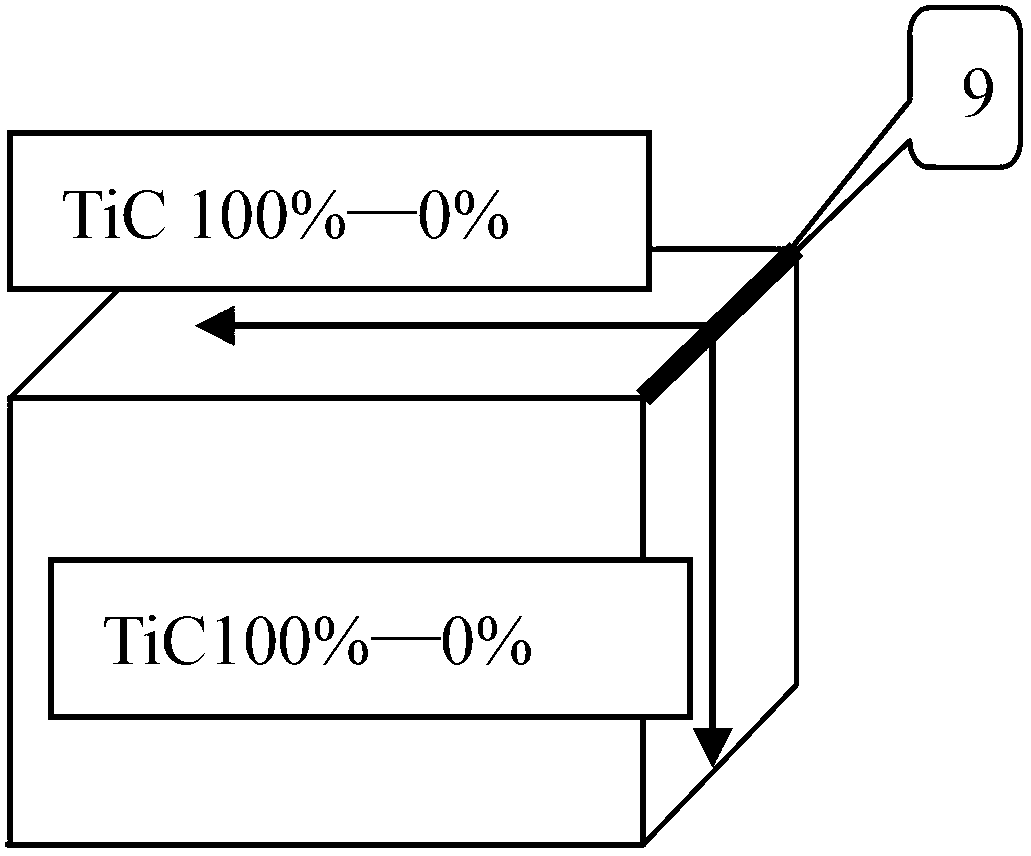

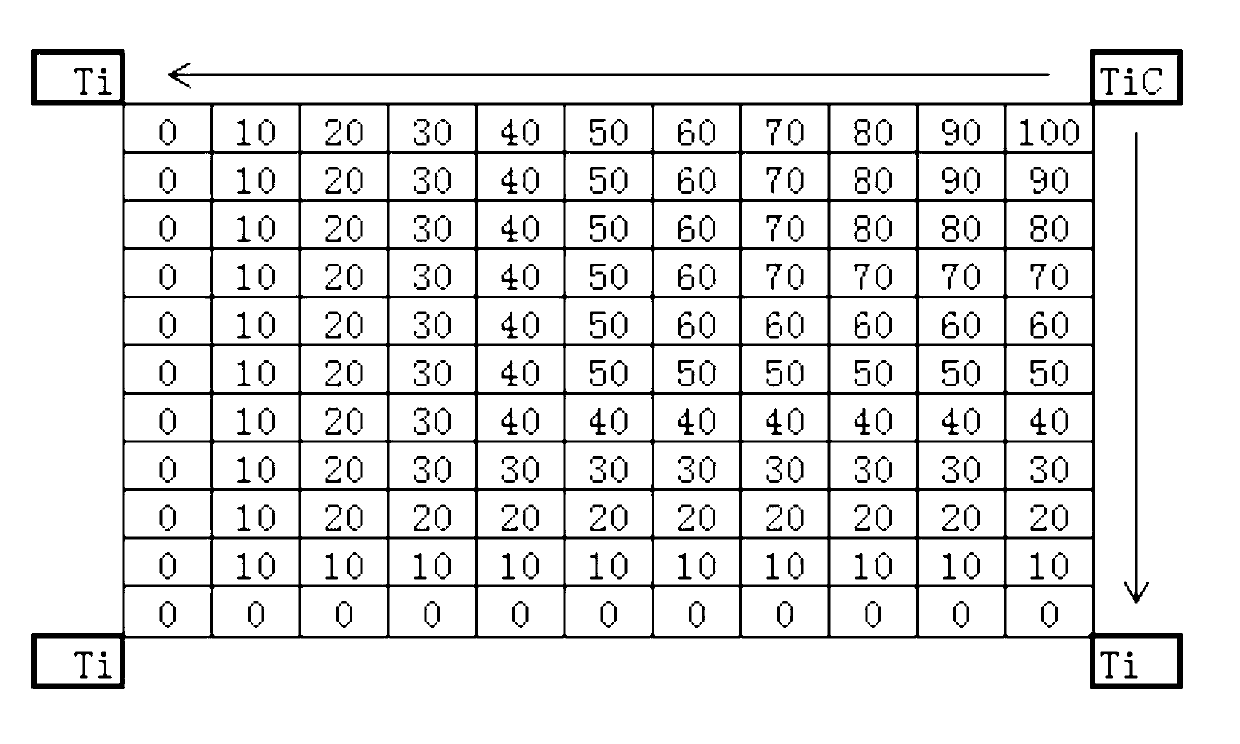

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. figure 1 Shown is a schematic diagram of a laser near-net shaping system for a metal-ceramic multi-dimensional functionally graded structural member. The embodiment of the present invention requires: forming such as figure 2 For a metal-ceramic functionally graded tool shown in the figure, Ti is used for the design of the metal material powder, and TiC is used for the ceramic powder. The 100%-0% gradient transition of TiC material, the material ratio design is shown in Table 1.

[0029] Table 1 Schematic diagram of gradient change design of cermet composition, where the value represents the percentage of TiC volume fraction.

[0030]

[0031] The JK1002 Nd:YAG solid-state continuous laser is used for near-net laser forming of metal and ceramic powders. The specific forming steps are as follows:

[0032] A. According to the requirements, select near-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com