Functionally graded material shape and method for producing such a shape

A technology of functionally graded materials and manufacturing methods, applied in chemical instruments and methods, thin material processing, metal layered products, etc., can solve the problems of cracks in the enrichment layer, reducing the plastic deformation and interface separation of the SUS316 enrichment layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

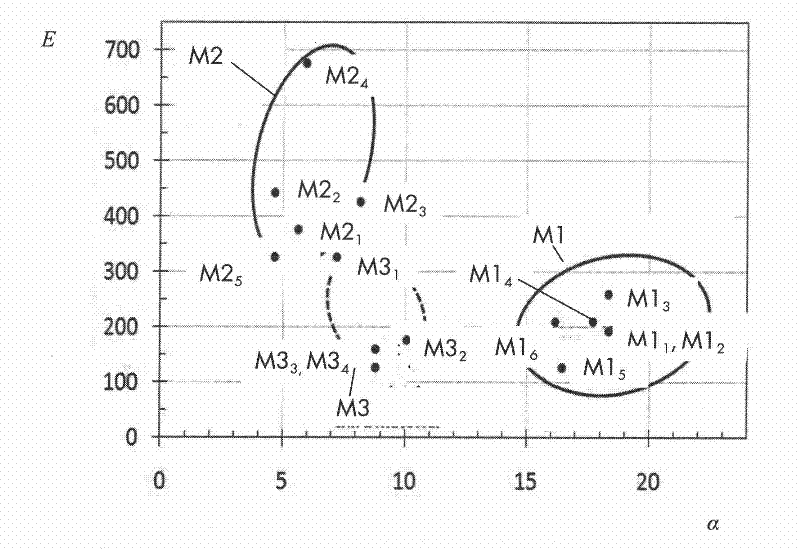

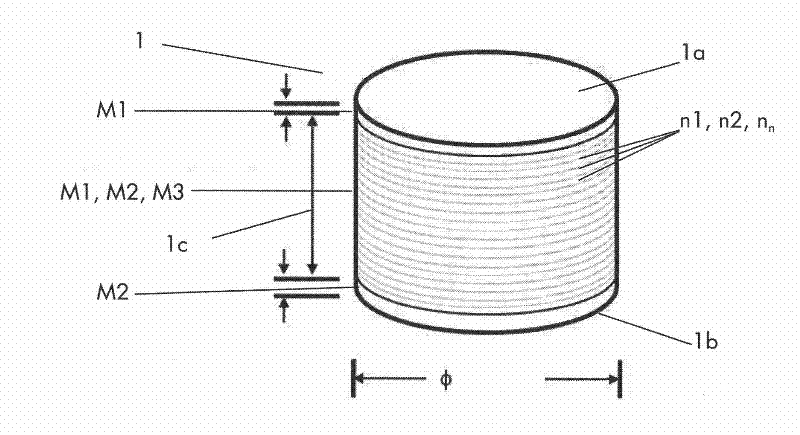

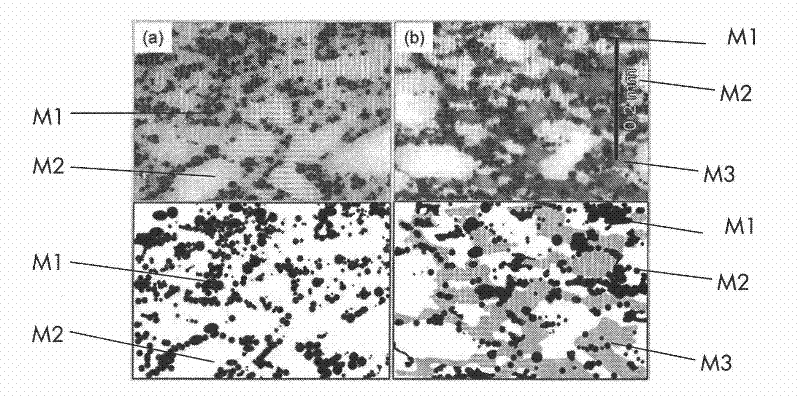

[0069] The first material M1 (specifically SUS316L) and the second material M2 (specifically Al 2 o 3 ) of cylindrical FGM shape 1, and is shown in Figure 4 In the optical micrograph of , in which: (a) a dense bulk FGM shape 1 containing different materials M1, M2 and M3; and (b) a multilayer structure containing different materials of the first, second and third materials Layers of mixture M1-M2-M3. 21 different powder blends were prepared with the following compositions:

[0070] Table 1

[0071] layer

Volume% of M1-SUS316L

M2-Al 2 o 3 volume of%

M3-ZrO 2 (3Y)volume%

1

100.0

0.0

0.0

2

95.0

2.7

2.2

3

90.0

5.0

4.5

4

85.0

8.3

6.8

5

80.0

10.9

8.9

6

75.0

13.7

11.2

7

70.0

16.5

13.5

8

65.0

19.3

15.8

9

60.0

22.0

18.0

10

55.0

24.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com