Method for controlling brittleness Laves phases in laser additive manufacturing process of nickel-based high-temperature alloy

A nickel-based superalloy, laser additive technology, applied in the direction of additive manufacturing, additive processing, energy efficiency improvement, etc., can solve the problem of not completely removing long-chain Laves, reduce cracking sensitivity, and reduce useful alloying elements. Segregation, the effect of reducing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 400W, the scanning speed is 6mm / s, the powder feeding amount is 8g / min, and the spot diameter is 1 ~2mm, carrier gas flow rate 10L / min;

[0024] S2. Use tap water to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0025] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a square wave. The parameters of the square wave are: peak power: 600W, pulse frequency: 10HZ-100HZ, duty cycle: 0.6.

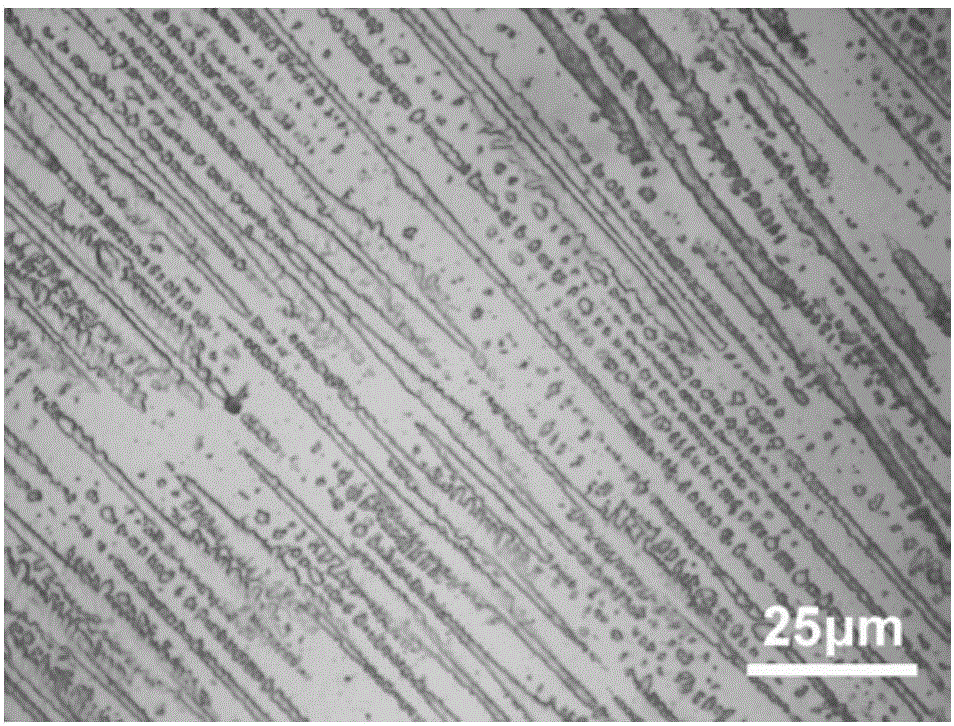

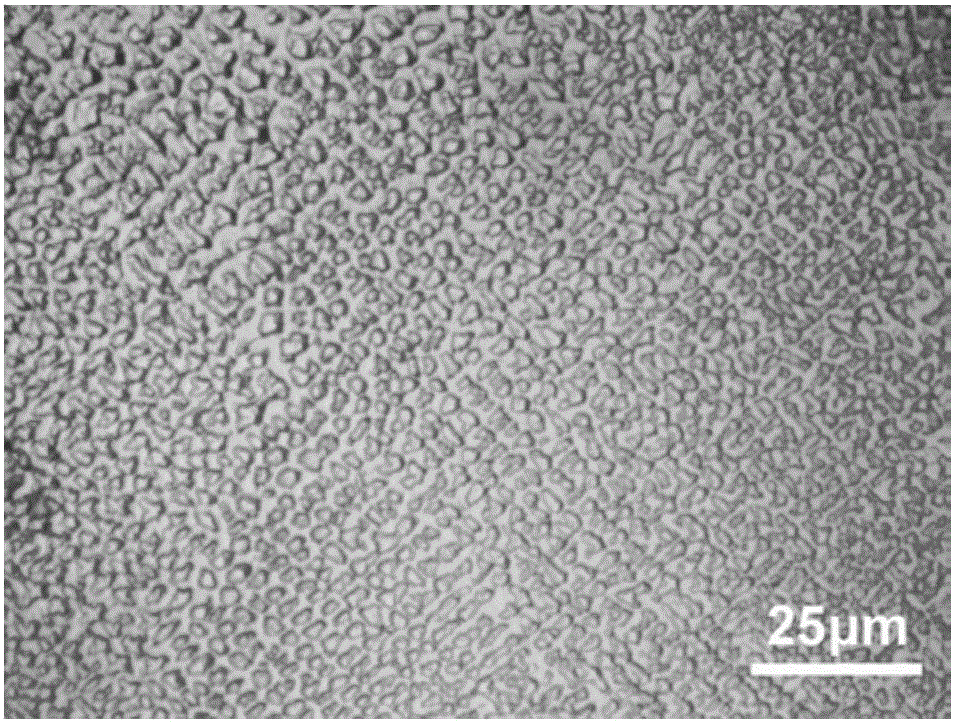

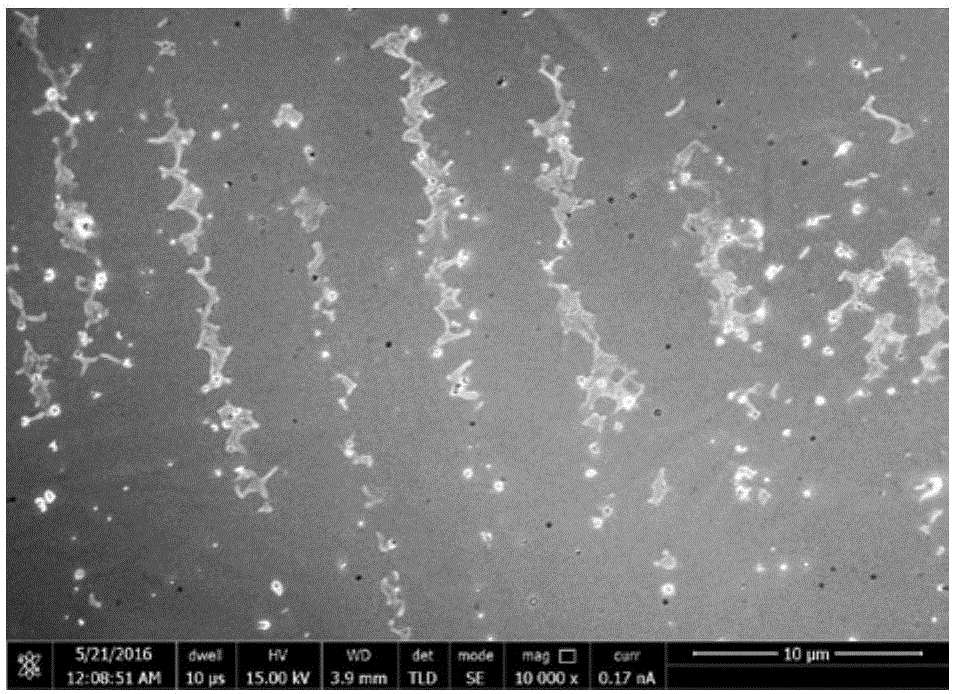

[0026] figure 2 It is the metallographic structure map obtained by adopting the laser modulation method of the present invention; from figure 2 It can be seen that the metallographic structure is composed of fine equiaxed dendrites; figure 1 The metallographic st...

Embodiment 2

[0032] S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 400W, the scanning speed is 10mm / s, the powder feeding amount is 12g / min, and the spot diameter is 1 ~2mm, carrier gas flow rate 12L / min;

[0033] S2. Use tap water to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0034] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a sawtooth wave. The parameters of the sawtooth wave are: peak 900W, valley 0W, pulse frequency: 90HZ.

Embodiment 3

[0036]S1. Preliminarily optimize the process parameters of laser additive manufacturing, obtain the preliminary laser additive manufacturing process window, and optimize the parameters: the average laser power is 600W, the scanning speed is 8mm / s, the powder feeding amount is 10g / min, and the spot diameter is 1mm , carrier gas flow rate 10L / min;

[0037] S2. Use liquid nitrogen to cool the bottom of the nickel-based substrate to reduce heat accumulation during the forming process;

[0038] S3. Carry out laser additive manufacturing of nickel-based superalloys. The laser light source is controlled by a sine wave. The parameters of the sine wave are: peak 700W, valley 0W, pulse frequency: 30HZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com