24CrNiMoRe alloy steel powder of laser additives and production method thereof

A laser additive and powder preparation technology, applied in additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems of limited mechanical processing equipment, high manufacturing cost, complex heat treatment process, etc., to promote application and rapid development. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The preparation method for laser additive manufacturing of 24CrNiMoRe alloy steel powder specifically includes the following steps:

[0069] Step 1, preprocessing:

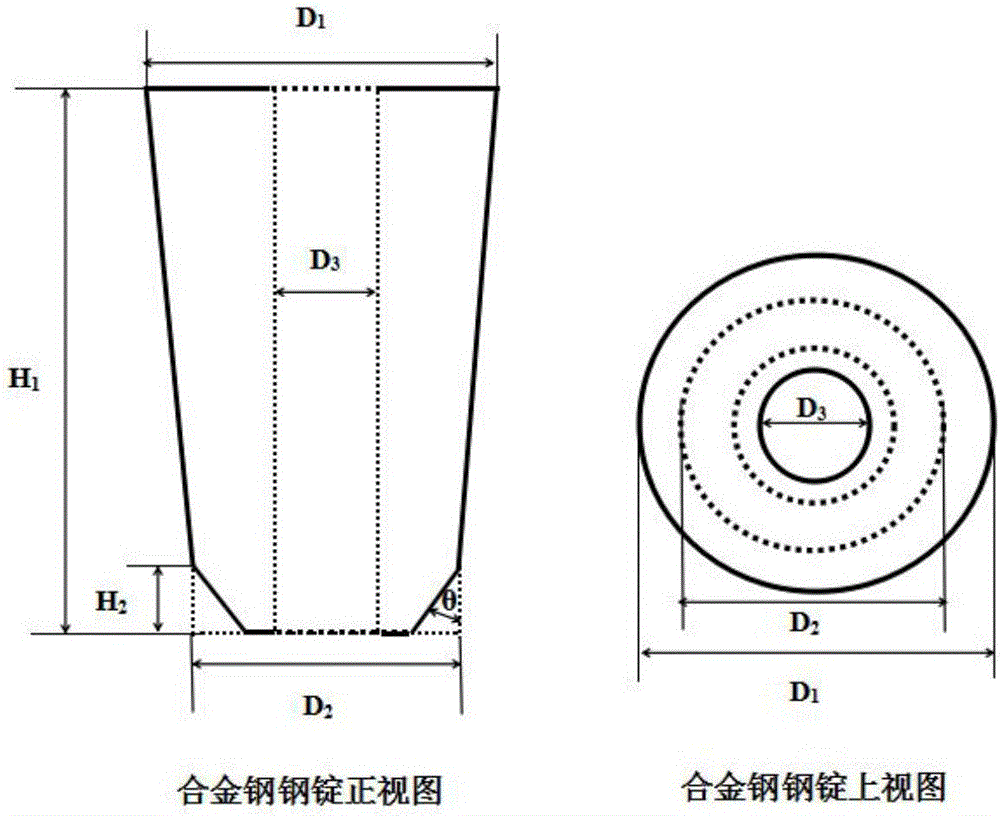

[0070] (1) The raw material 24CrNiMoRe alloy steel is made into a circular truncated steel ingot, the diameter of the upper surface of the circular truncated steel ingot is D 1 For Φ105mm, the diameter of the lower surface D 2 Φ90mm, height H 1 is 200mm; through holes are machined in the center of the ingot, the diameter of the through holes is D 3 is Φ20mm; then the lower surface of the ingot is processed to a height H 2 It is 25mm, the chamfering angle θ is a 40° slope so that it is tightly assembled with the bottom of the crucible, and the inner and outer surface roughness of the steel ingot is Ra13.0;

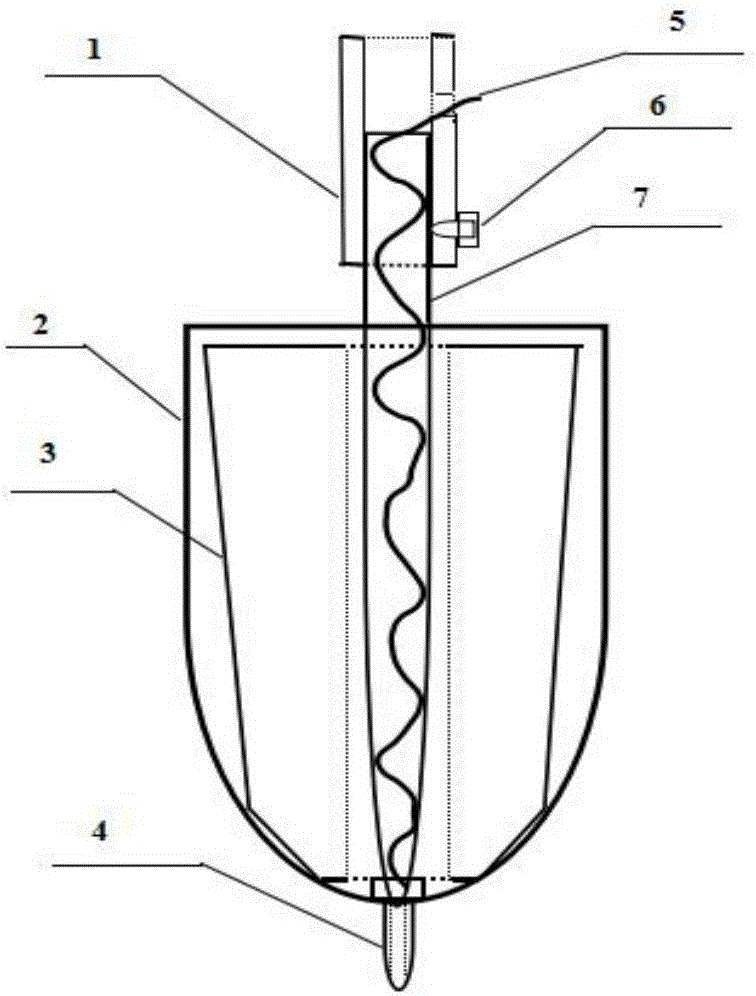

[0071] (2) Clean the processed 24CrNiMoRe alloy steel ingot and place it in the crucible induction melting atomization device. The specific operations are:

[0072] Use 1000-2000 metallographic sand...

Embodiment 2

[0105] The preparation method of laser additive manufacturing 24CrNiMoRe alloy steel powder specifically includes the following steps:

[0106] Step 1, preprocessing:

[0107] (1) The raw material 24CrNiMoRe alloy steel is made into a circular truncated steel ingot, the diameter of the upper surface of the circular truncated steel ingot is D 1 For Φ105mm, the diameter of the lower surface D 2 Φ90mm, height H 1 is 200mm; through holes are machined in the center of the ingot, the diameter of the through holes is D 3 is Φ30mm; then the lower surface of the ingot is processed to a height H 2 It is 30mm, the chamfering angle θ is 50° slope, so that it can be assembled more closely with the bottom of the crucible, and the inner and outer surface roughness of the steel ingot is Ra15.0;

[0108] (2) Clean the processed 24CrNiMoRe alloy steel ingot and place it in the crucible induction melting atomization device. The specific operations are:

[0109] Use 1000-2000 metallographic ...

Embodiment 3

[0142] The preparation method of laser additive manufacturing 24CrNiMoRe alloy steel powder specifically comprises the following steps:

[0143] Step 1, preprocessing:

[0144] (1) The raw material 24CrNiMoRe alloy steel is made into a truncated steel ingot, and the diameter of the upper surface of the truncated steel ingot is D 1 Φ105mm, lower surface diameter D 2 Φ90mm, height H 1 is 200mm; a through hole is processed in the center of the steel ingot, and the diameter of the through hole is D 3 Φ30mm; then process the lower surface of the ingot to a height H 2 28mm, the chamfer angle θ is 45° so that it fits closely with the bottom of the crucible, and the roughness of the inner and outer surfaces of the ingot is Ra15.0;

[0145] (2) Clean the processed 24CrNiMoRe alloy steel ingot and place it in the crucible induction melting atomization device. The specific operation is:

[0146] Use No. 1000-2000 metallographic sandpaper to remove oxides and impurities on the surfac...

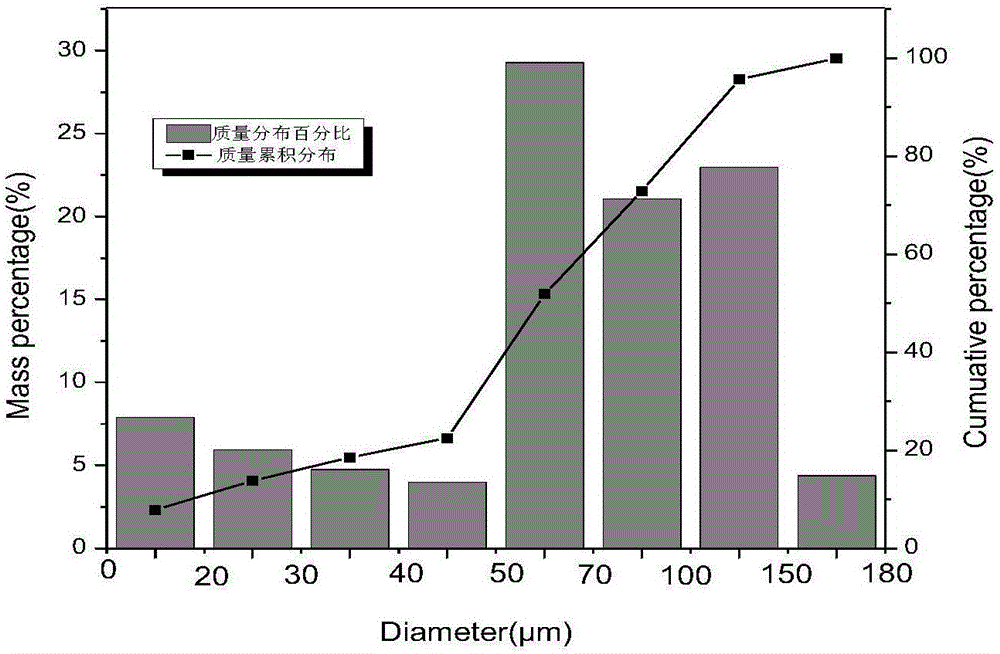

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com