Spherical TC4 titanium alloy powder used for laser 3D printing and preparation method thereof

A 3D printing, titanium alloy technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., to achieve the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

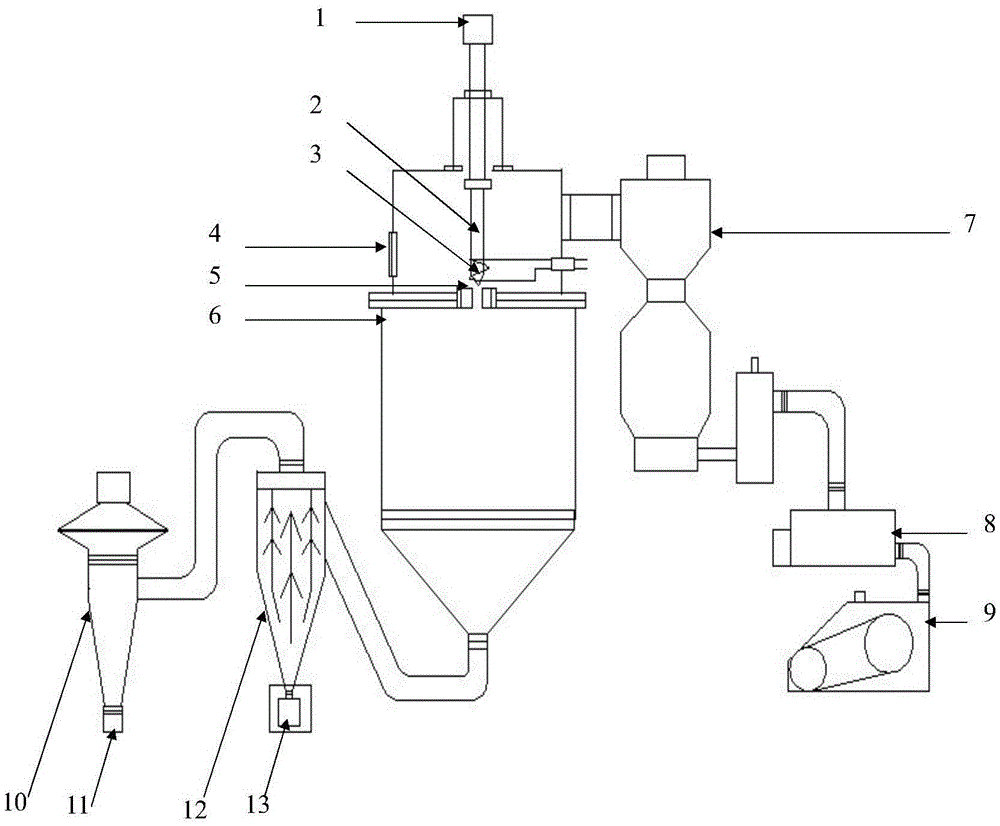

[0067] The preparation method of the spherical TC4 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0068] Step 1, preprocessing:

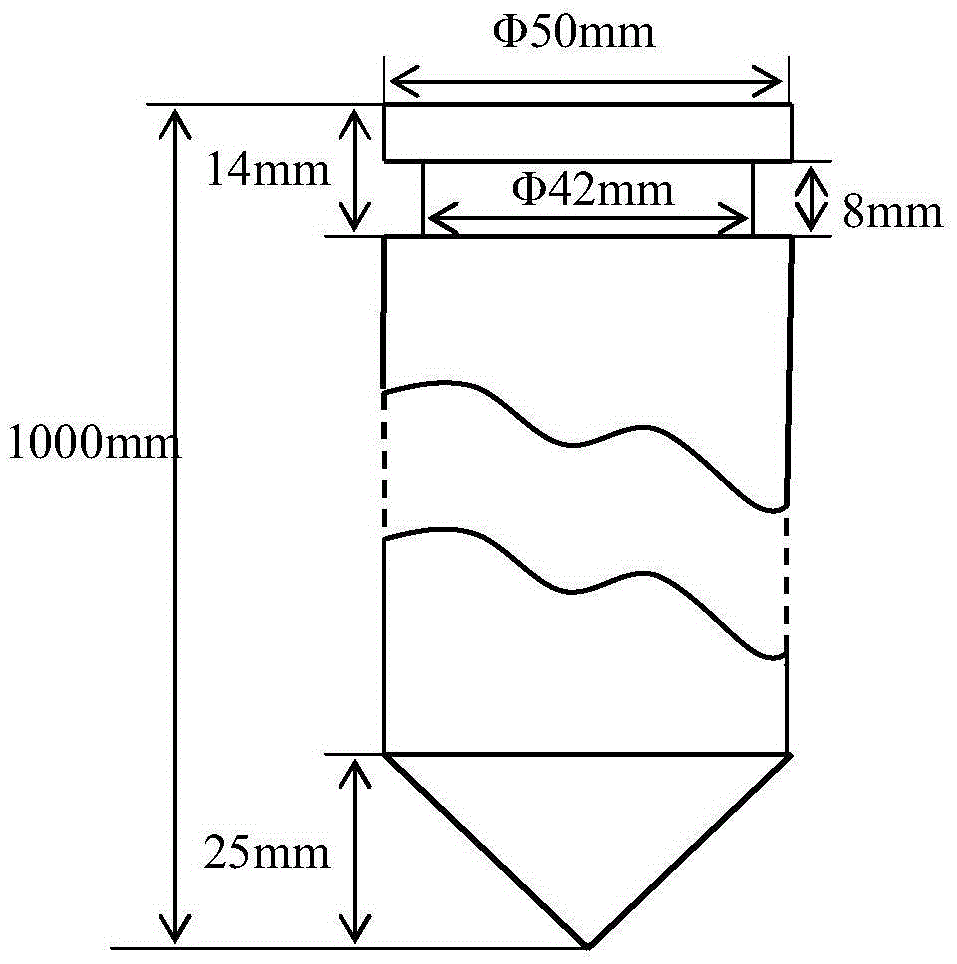

[0069] (1) The raw material TC4 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 40-degree conical tip with a surface roughness of Ra12.5 , at the other end of the electrode titanium rod, at a distance of 6mm from the top, process an annular slot with a width of 8mm and a depth of 4mm;

[0070] (2) Clean the electrode titanium rod and install it on the electrode control system of 10kg rotating electrode vacuum induction melting. The specific operation is as follows:

[0071] Use No. 1000-2000 metallographic sandpaper to remove oxides and impurities on the surface of the TC4 electrode titanium rod, clean the surface of the TC4 electrode titanium rod with petroleum...

Embodiment 2

[0105] The preparation method of the spherical TC4 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0106] Step 1, preprocessing:

[0107] (1) The raw material TC4 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 45-degree conical tip with a surface roughness of Ra15. At the other end of the titanium rod, at a distance of 6mm from the top, process an annular slot with a width of 8mm and a depth of 4mm;

[0108] (2) Clean the electrode titanium rod and install it on the electrode control system of 10kg rotating electrode vacuum induction melting. The specific operation is as follows:

[0109] Use 1000-2000 No. metallographic sandpaper to remove oxides and impurities on the surface of the TC4 electrode titanium rod, clean the surface of the TC4 electrode titanium rod with petroleum ether and al...

Embodiment 3

[0145] The preparation method of the spherical TC4 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0146] Step 1, preprocessing:

[0147] (1) The raw material TC4 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 50-degree conical tip with a surface roughness of Ra12.5 , at the other end of the electrode titanium rod, at a distance of 6mm from the top, process an annular slot with a width of 8mm and a depth of 4mm;

[0148] (2) Clean the electrode titanium rod and install it on the electrode control system of 10kg rotating electrode vacuum induction melting. The specific operation is as follows:

[0149] Use 1000-2000 No. metallographic sandpaper to remove oxides and impurities on the surface of the TC4 electrode titanium rod, clean the surface of the TC4 electrode titanium rod with petroleum...

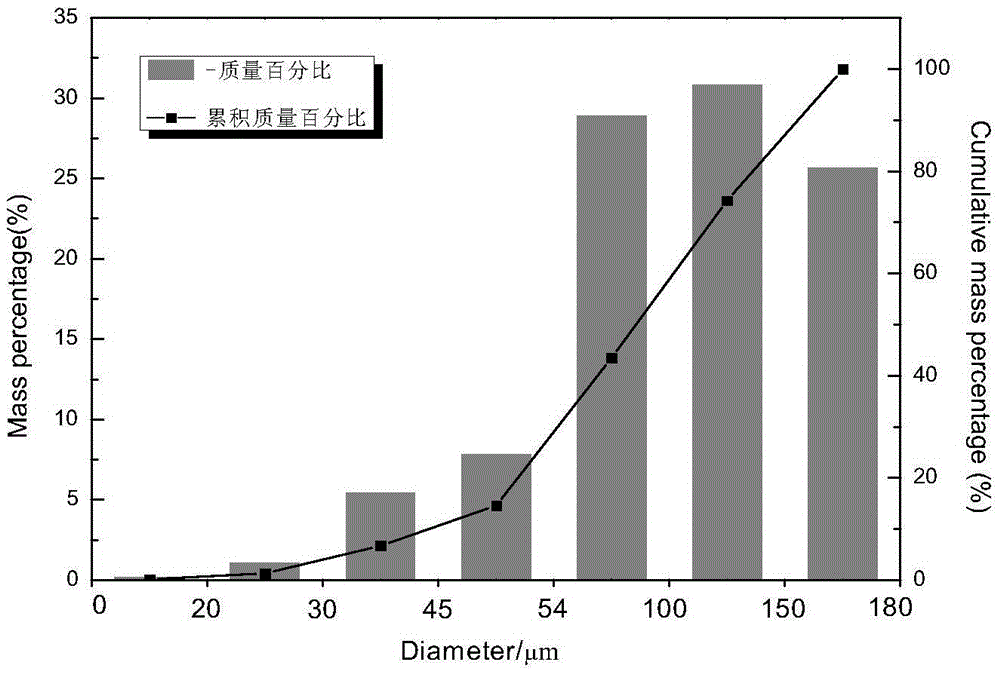

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com