Low floor rail flat car, bogie and welding method

A bogie and low-floor technology, applied in bogies, welding equipment, transportation and packaging, etc., can solve the problems of inability to meet the requirements of subway flat cars, large longitudinal positioning rigidity of wheels, and inability to meet subway flat cars, etc. Light weight, reduced installation height, and small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

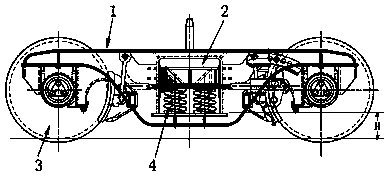

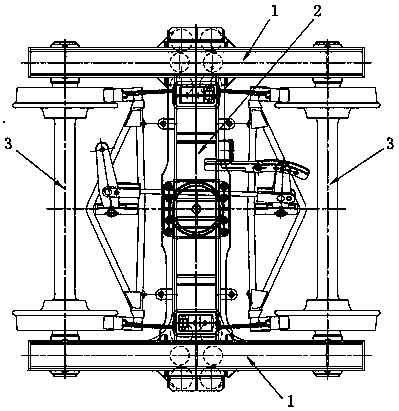

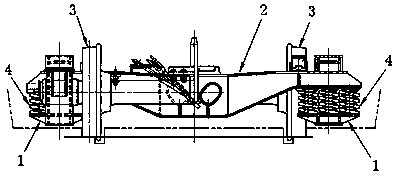

[0039] Example: such as Figures 1 to 3 As shown, a three-piece bogie with a low load-bearing surface welded type includes: two side frames 1 and a bolster 2 assembled, and also includes: two sets of wheels 3 and springs 4; the wheels 3. It consists of an axle, two wheels and two sets of bearings. The bearings are set on both ends of the axle, and the wheels are set on the bearings; The card frame 14 of the wheel set is installed, and the position of the central symmetrical axis of the side frame 1 is provided with an axle box 15; The side bearing box 26 is provided at the position close to the bolster neck 29; the wheel set 3 is stuck in the frame 14 at both ends of the side frame 1, and the bolster necks 29 at the two ends of the bolster 2 are respectively stuck in the In the axle boxes 15 of the two side frames, a spring 4 is vertically installed at the bottom of the axle boxes 15 to support the bolster 2; The parts are all formed by welding steel plates.

[0040] This w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com