Longitudinal beam of trailer

A longitudinal beam, height technology, applied in vehicle components, substructure, transportation and packaging, etc., can solve the problems of low bearing capacity and high bearing surface

Inactive Publication Date: 2015-03-25

SHANDONG JIUZHOU AUTOMOBILE MFG

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to research and develop based on the lightweight form of the trailer, solve the technical problems of low bearing capacity and high bearing surface of the traditional trailer longitudinal beam, improve the overall strength of the longitudinal beam and reduce the height of the bearing surface while reducing cost and weight

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

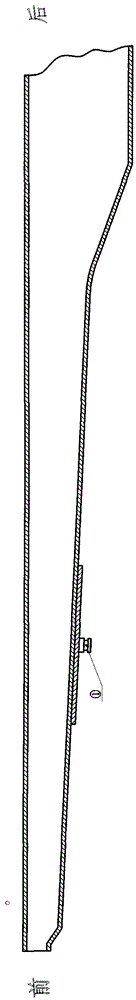

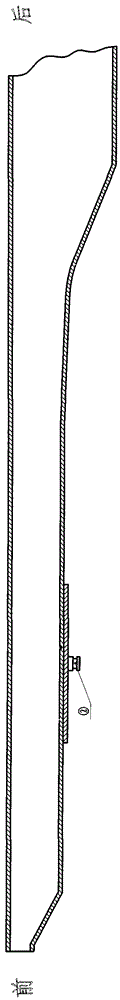

[0008] According to the side view of the stringer ( figure 1 ) The longitudinal beam of the trailer of the present invention, the height of the traction pin ① decreases from the rear to the front, which improves the overall load-bearing capacity of the longitudinal beam and the running stability of the vehicle while reducing the load-bearing height and its own weight.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of car manufacturing, and relates to a longitudinal beam of a trailer. The technical problems that a traditional longitudinal beam of the trailer is insufficient in strength and not high in bearing capacity, and a bearing face is high are solved. The height of a traction pin (rotary disc) of the longitudinal beam is gradually decreased from back to front, the height of the bearing face is reduced, trailer running stability is improved, the height of the traction pin (rotary disc) of the longitudinal beam is gradually decreased from back to front, the principle that the closer the position is to the traction pin (rotary disc), the smaller torque is, and the lower the requirement for the strength of the longitudinal beam is ingeniously utilized, raw materials are saved on the premise of guaranteeing the same bearing strength requirement, and the car light level is improved. Due to the fact that the height of a frame on the traction pin (rotary disc) decides the height of the bearing face of the trailer, the height of the position, on the traction pin (rotary disc), of the frame is greatly lowered relative to an original structure through the structure, meanwhile, the bearing face is lowered, and the trailer running stability is greatly improved. The longitudinal beam is suitable for various trailers.

Description

1. Technical field [0001] The invention belongs to the field of automobile manufacturing and relates to a longitudinal beam of a trailer. 2. Background technology [0002] The traction pin (turntable) of the trailer longitudinal beam of the traditional structure is parallel up and down, and the front and rear are of the same height structure. This structure consumes a lot of materials to achieve load-bearing strength and has a high load-bearing surface, resulting in low running stability of the whole vehicle. 3. Contents of the invention [0003] The purpose of the present invention is to solve the technical problems of low bearing capacity and high bearing surface of traditional trailer longitudinal beams based on the lightweight form of trailers, improve the overall strength of the longitudinal beams and reduce the height of the bearing surface while reducing cost and weight. [0004] The utility model relates to a longitudinal beam of a trailer, which is characterized i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B62D21/02

CPCB62D21/20

Inventor 孙复森

Owner SHANDONG JIUZHOU AUTOMOBILE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com