Dumper truck and its carriage underbed

A technology of dump truck and carriage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the chassis of the forward dump truck according to the present invention will be described in detail below in conjunction with the accompanying drawings.

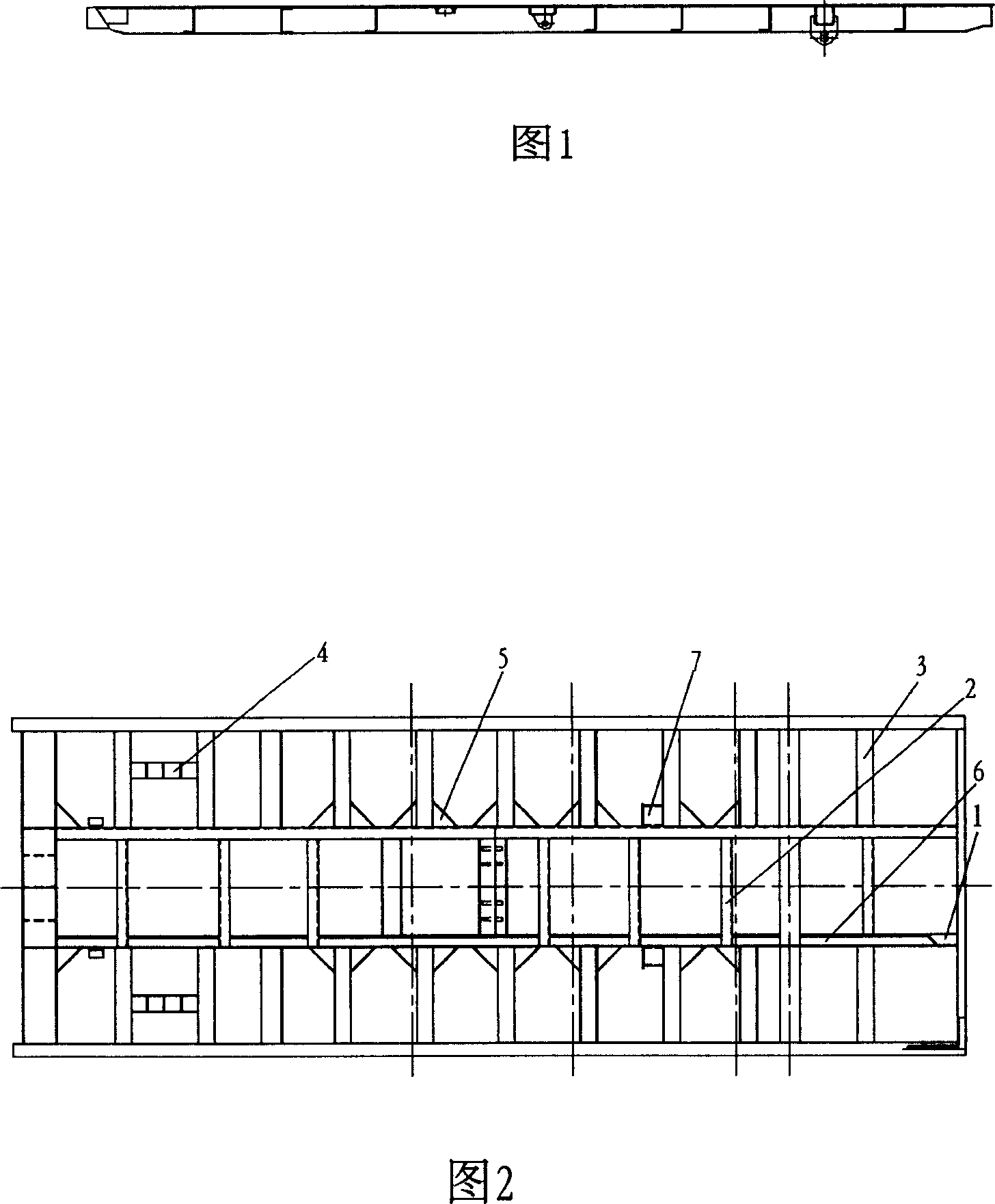

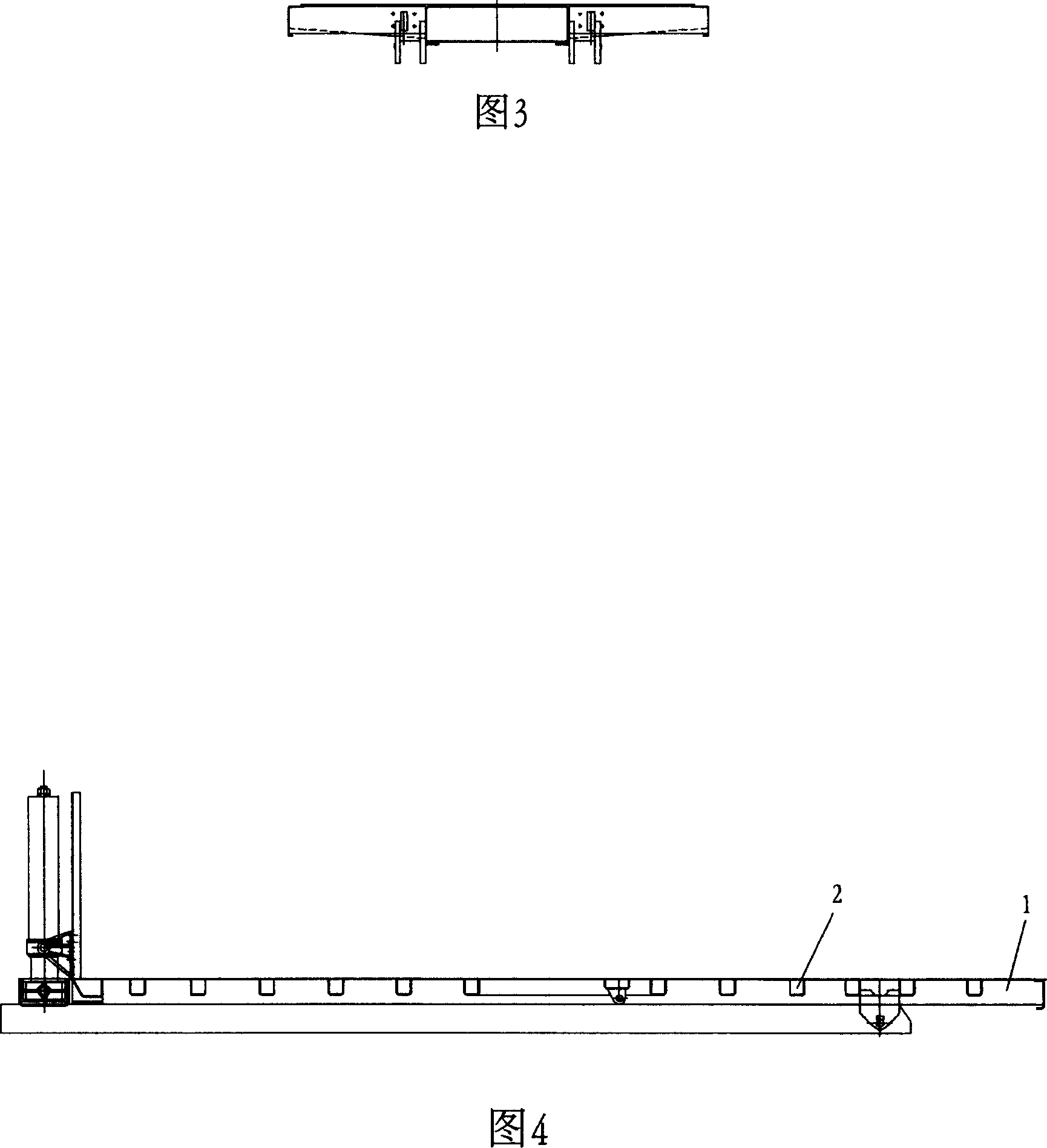

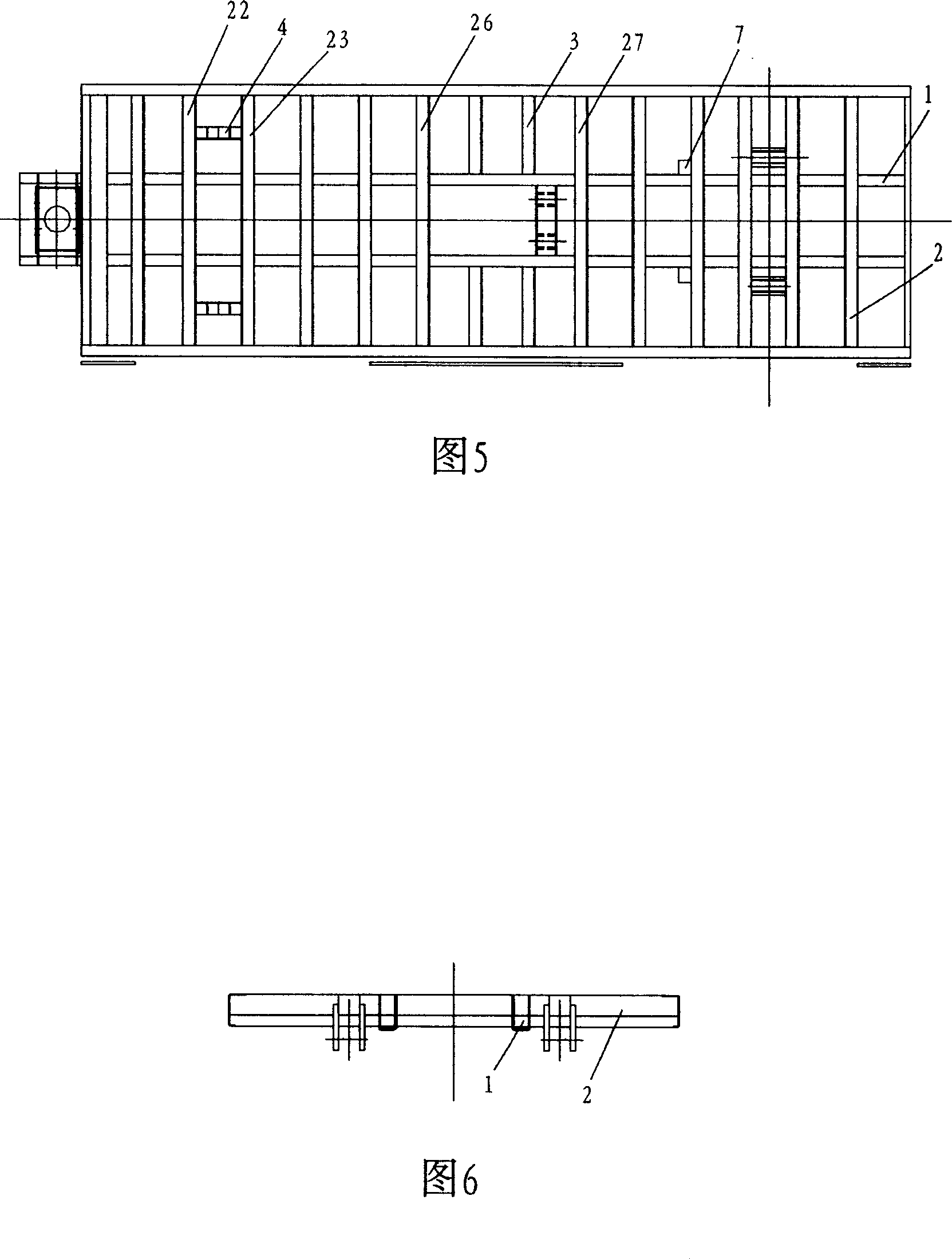

[0024] Please refer to Fig. 4, 5 and Fig. 6, Fig. 4 is the front view of the carriage chassis of the forward dump truck according to the present invention; Fig. 5 is a top view of the carriage chassis of the forward dump truck according to the present invention; Fig. 6 is A side view of the bed frame of the forward tipping dump truck according to the present invention. In order to simplify the expression, other components in the dump truck that are the same as those in the prior art are omitted in the figure.

[0025] The compartment underframe of the dump truck of the present invention includes longitudinal beams 1, cross beams 2, wing struts 3, longitudinal struts 4, shim irons 7 and the like. The longitudinal beam 1 adopts a channel-shaped profile whose leg height is greater than the wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com