Brick top cutting device

A cutting device and brick technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of slow cutting speed, low cutting quality, noise pollution and dust of cutting wheels, and achieve accurate cutting operations and avoid unsightly Clear, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

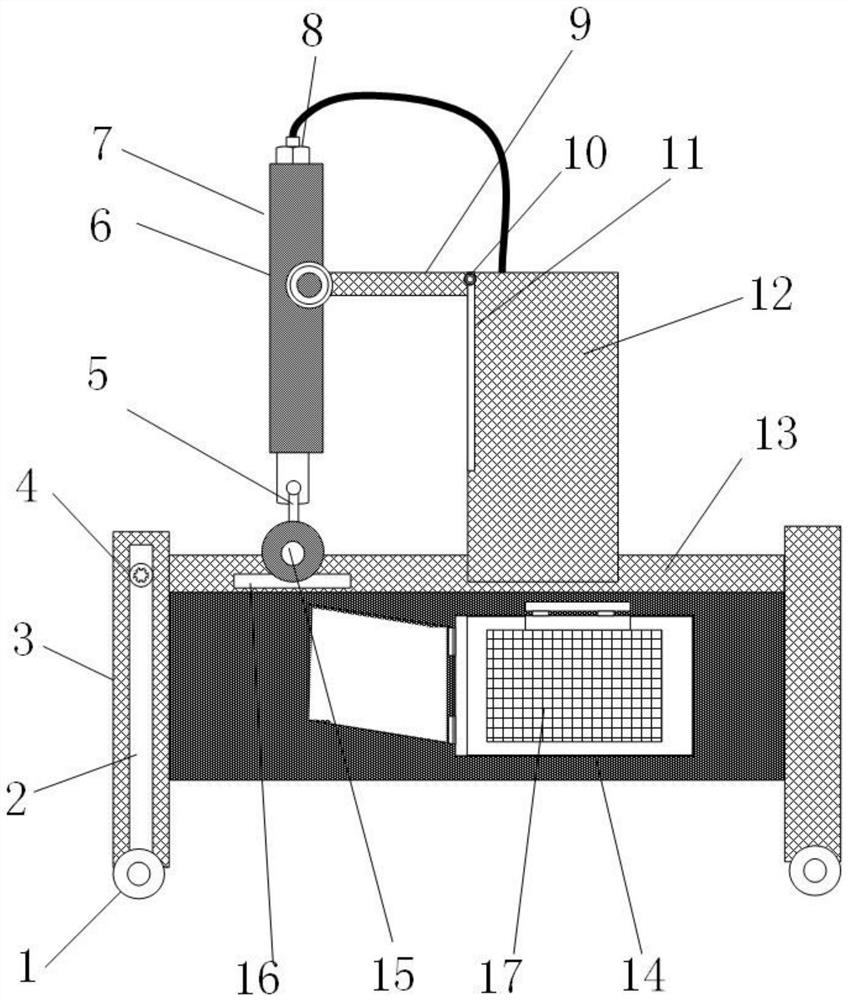

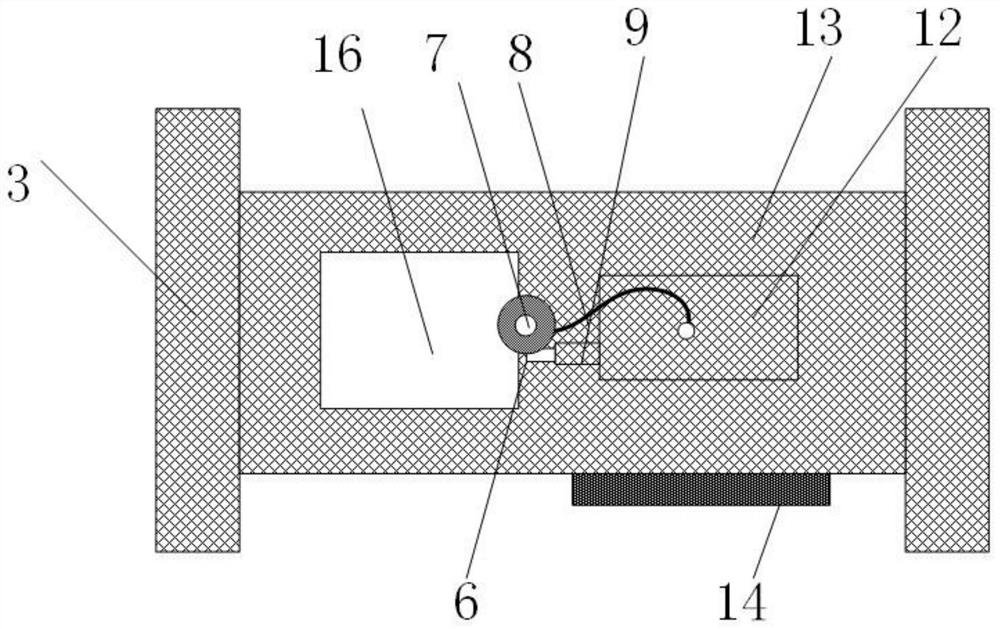

[0022] As a preferred embodiment of the present invention, the bottom end of the lifting rail 2 is fixed with a 360-degree moving wheel 1, and the moving wheel 1 and the lifting rail 2 are both artificial external control mechanical structures.

[0023] As a preferred embodiment of the present invention, the platform adjustment knob 4 is a cutting drum roll adjustment knob.

[0024] As a preferred embodiment of the present invention, the chain rod 5 is a cylindrical metal chain rod with certain elasticity, and the roller 10 is a sliding metal roller in centimeter units.

[0025] As a preferred embodiment of the present invention, the sliding cutting of the main beam 3, the platform adjustment knob 4, the roller 10, the cutting panel 13 and the cutting wheel 15 constitutes the main brick top cutting device structure.

[0026] The main prominent features of the present invention: the brick top cutting device is provided with a working adjustment structure for cutting and cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com