Early-removing independent support strip

A technology of strips and support heads, which is applied to the joints of formwork/formwork/work frame, the treatment of formwork, and the preparation of building components on site, etc., which can solve the problem of limited support area, affecting force and stability, No problems such as independent support can be achieved, and the effect of small contact area, reasonable design and reasonable load bearing can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

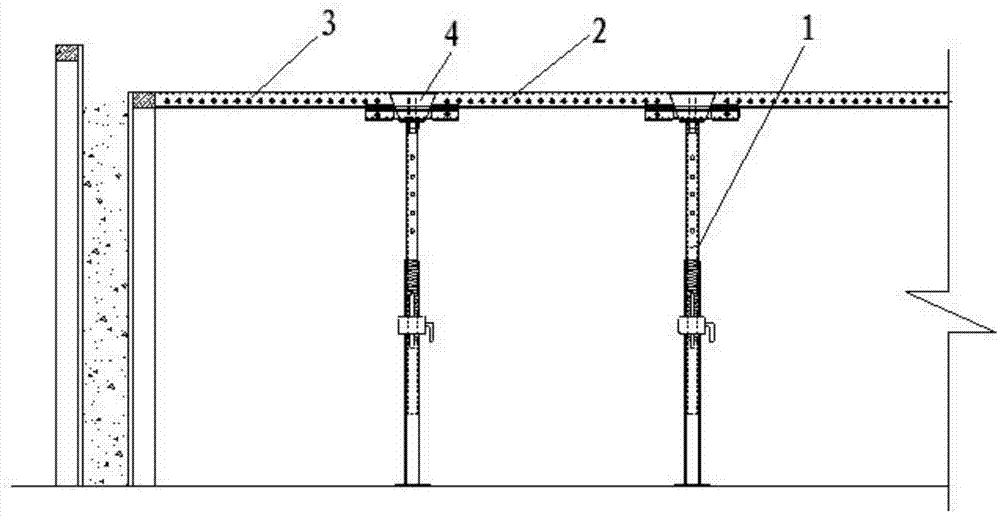

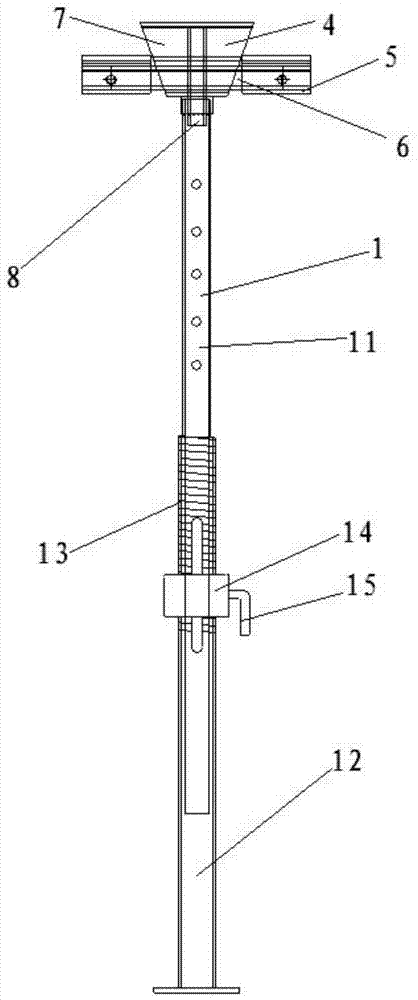

[0033] Such as Figure 1-6 As shown, an early demolition independent support strip is a plurality of early demolition devices arranged in parallel. The early demolition device includes: a steel support 1, a standard keel 2 and a side keel 3, and is characterized in that it also includes a roof support Head 4, connecting plate 5 and connecting rib 6, the lower end of the roof supporting head 4 is connected with the steel support 1, and the left and right ends of the roof supporting head 4 pass through the connecting plate 5 and connecting rib 6 respectively Connect with the standard keel 2 and the side keel 3.

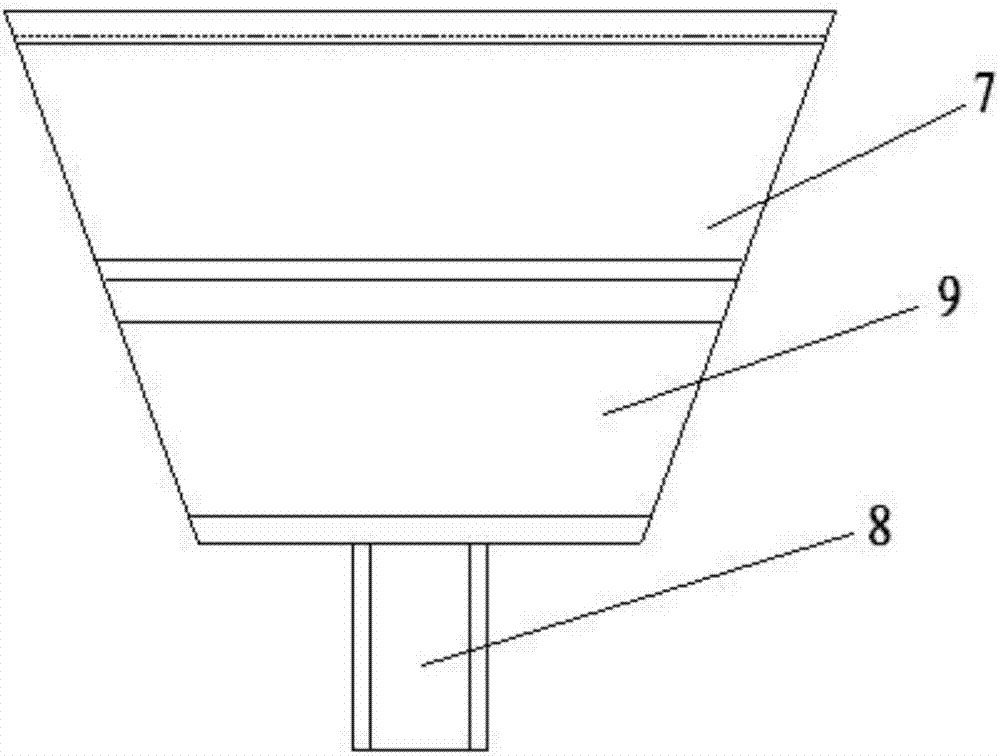

[0034] The roof support head 4 includes a trapezoidal support head 7 with a large top and a small bottom and a support rod 8 for inserting the steel support 1. The support head 7 and the support rod 8 are integrally formed, and the roof support head 4 is Cast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com