A scissor type aerial work platform with movable hinge point

An aerial work platform and work platform technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, lifting equipment safety devices, etc. and energy waste, to reduce system energy consumption, ensure reliability, and reduce performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described more clearly and completely below in conjunction with the accompanying drawings in the technical solution of the present invention.

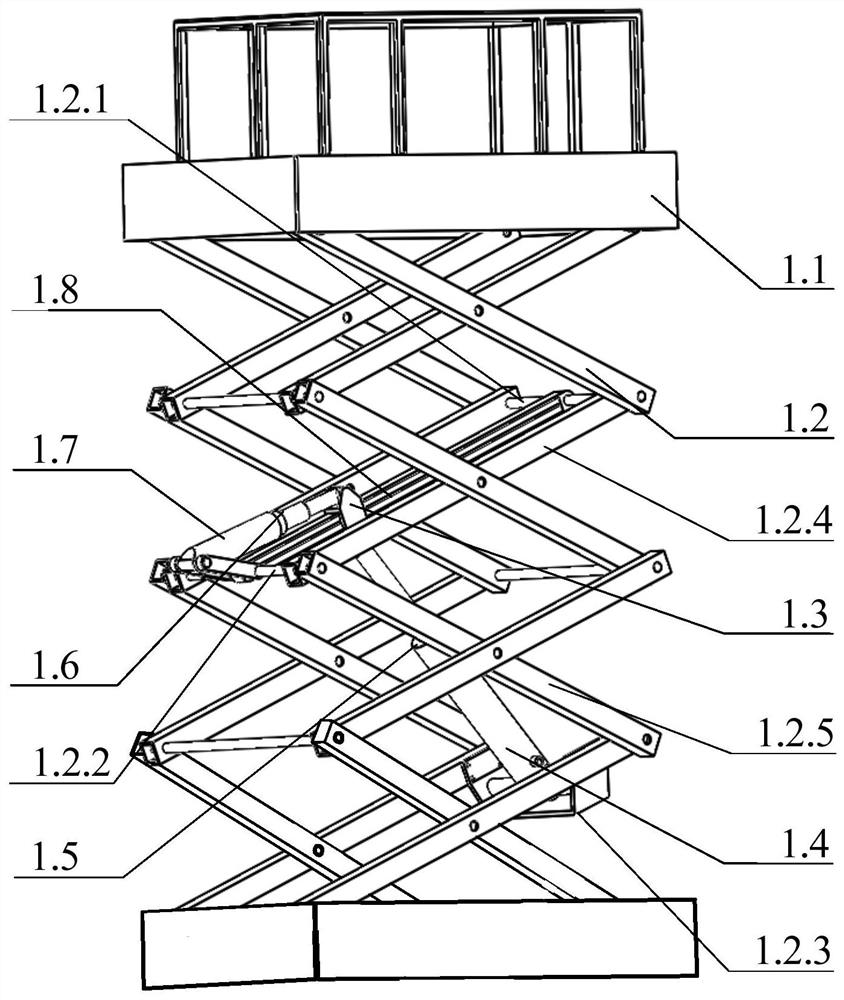

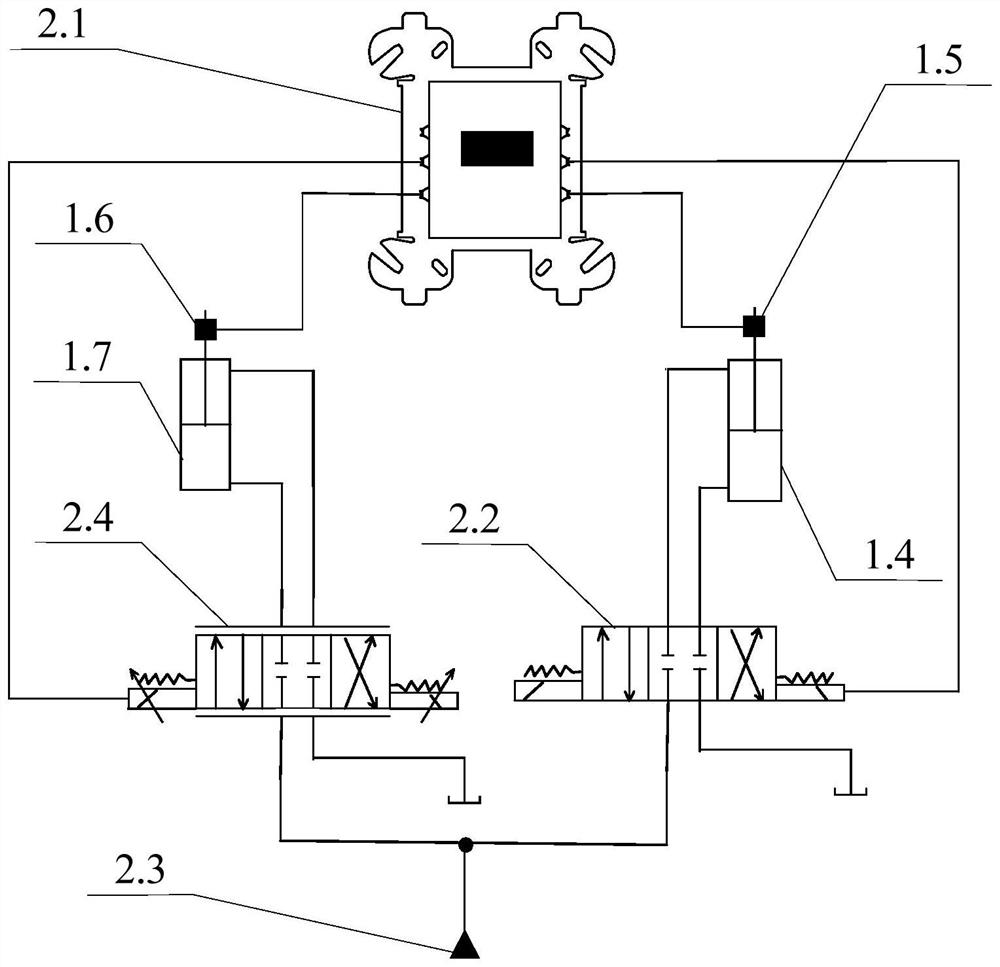

[0024] see figure 1 A platform structure of a scissor-type aerial work platform with a movable hinge point includes a working platform 1.1, a scissor mechanism 1.2, a movable hinge point 1.3, a lifting cylinder 1.4, a lifting displacement sensor 1.5, a hinge point displacement sensor 1.6, Hinge point oil cylinder 1.7 and moving guide rail 1.8; Among them, on the adjacent two groups of scissor bars 1.2.4 and 1.2.5 of scissor mechanism 1.2, beam one 1.2.1, beam two 1.2.2 and beam are distributed from top to bottom 3.1.2.3; the working platform 1.1 is hinged on the top of the scissor mechanism 1.2; the scissor mechanism 1.2 is composed of multiple groups of scissor rods hinged in turn, and the hinge points of two adjacent groups of scissor rods 1.2.4 and 1.2.5 Jointly fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com