Quick transportation tool based on hydraulic car for panel cabinets

A fast transportation, hydraulic technology, applied in transportation and packaging, motor vehicles, trolleys, etc., can solve the problems of crushing, time-consuming, labor-intensive, physical and other problems, and achieve the effect of reasonable load-bearing, improved safety, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions of the present invention more clearly expressed, the present invention will be further described below with reference to the accompanying drawings and embodiments.

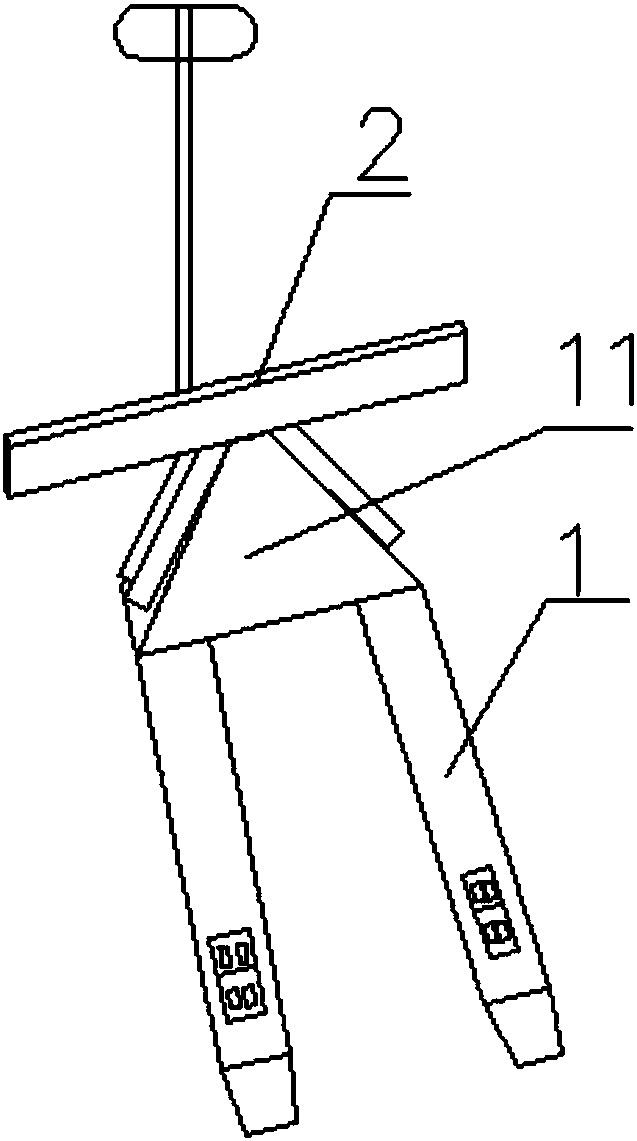

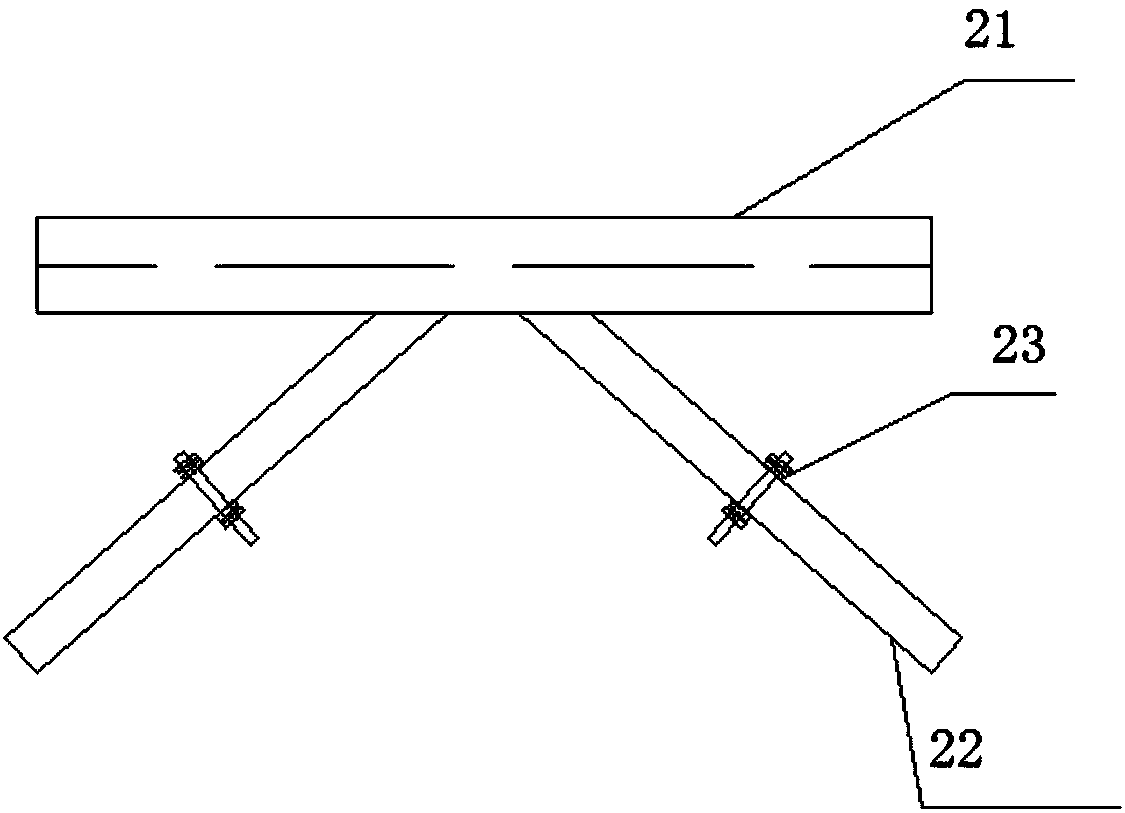

[0019] A rapid transport tool for a panel cabinet based on a hydraulic vehicle, comprising a hydraulic vehicle frame body 1, a triangular connecting bracket 11 is provided at the front end of the frame body 1, and a pallet bracket 2 is also installed on the connecting bracket 11, The pallet support 2 includes a strip-shaped support 21 and two legs 22 fixedly installed on the lower side of the strip-shaped support 21. The included angle of the two legs 22 is the same as the included angle of the top end of the connecting support 11.

[0020] The strip support 21 and the legs 22 of the pallet support 2 are made of channel steel, and the strip support 21 is fabricated by butt welding of two #10 channel steels.

[0021] In order to facilitate disassembly without damaging the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com