Corrugated web prestress FRP-concrete combined box beam and construction method thereof

A corrugated web and concrete technology, used in bridges, bridge materials, bridge construction, etc., can solve problems such as low overall stiffness, weak FRP-concrete interface, and heavy structure, so as to reduce the concentration of interface stress and enhance anti-peeling ability. , to avoid the effect of tensile cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

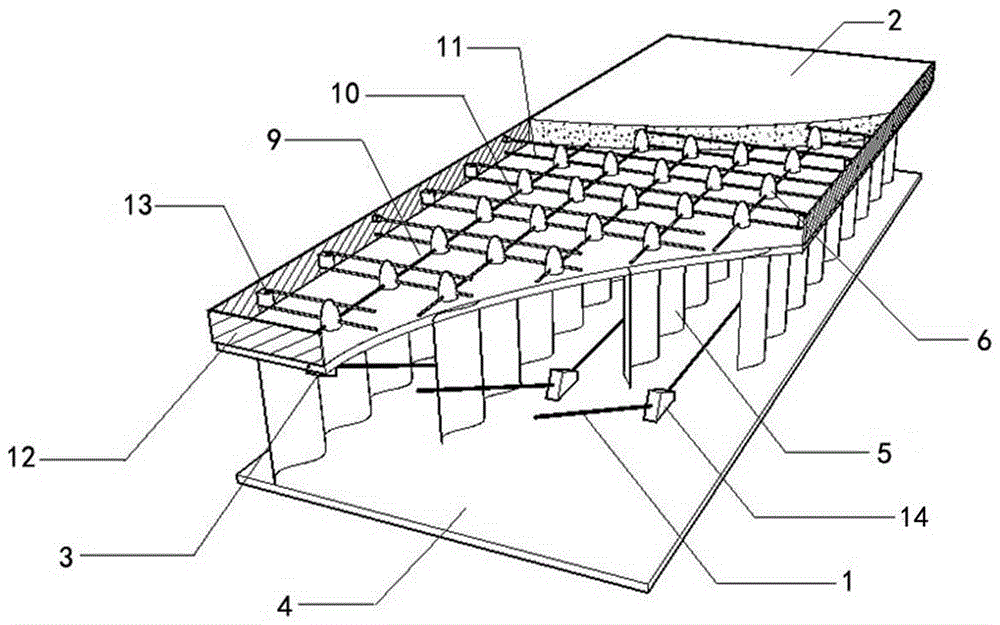

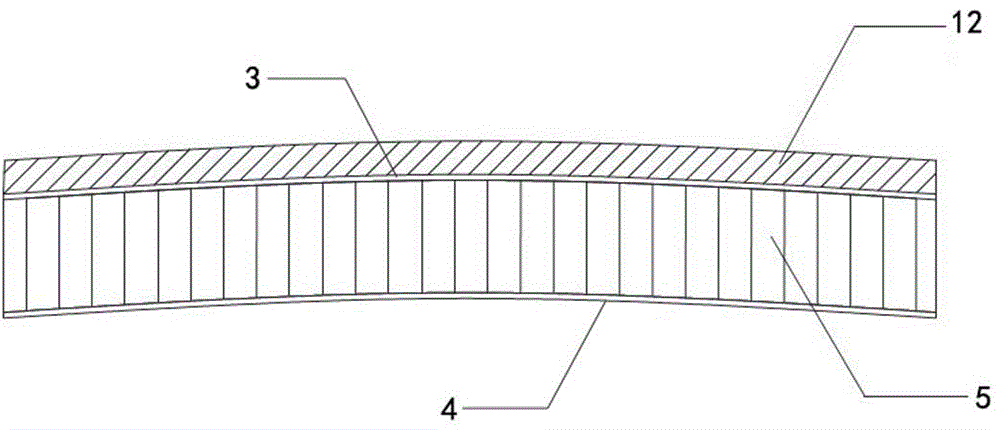

[0017] Corrugated web prestressed FRP-concrete composite box girder, including FRP box girder, said FRP box girder includes top plate 3, bottom plate 4 and several corrugated webs 5 supported and connected between top plate 3 and bottom plate 4, top plate 3 and bottom plate The corrugated webs 5 adjacent to each other form a box girder box room; each box girder box room is equipped with external prestressed tendons 1, and the two ends of the external prestressed tendons 1 are respectively connected to the longitudinal ends of the top plate 3, and the tension Pulling can make the FRP box girder produce pre-camber along the height direction;

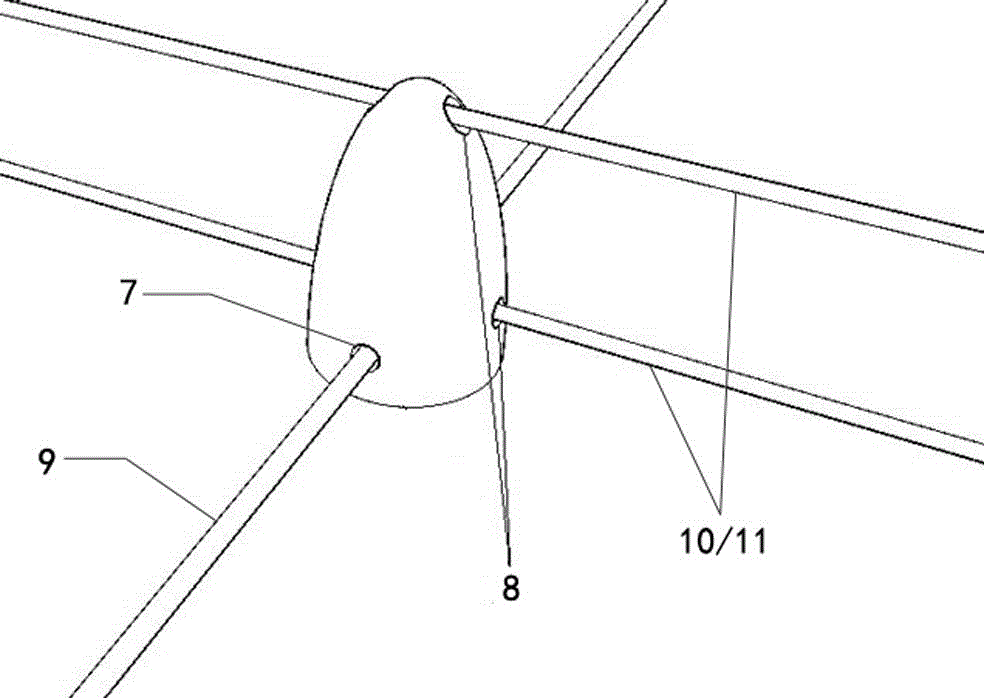

[0018] The top surface of the top plate 3 is protruded with a number of semi-elliptical spheres 6 distributed in a grid shape, and each semi-elliptical sphere 6 is reserved with a longitudinal channel 7 along the length direction of the bridge, and a transverse channel 8 is reserved along the width direction of the bridge; 7 is intersperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com