Middle or low speed magnetic suspension train running mechanism with the air spring positioned in the middle

A technology for maglev trains and air springs, which is applied in electric vehicles, vehicle components, devices for lateral relative movement between the underframe and the bogie, etc. The gap increases, which affects the running speed of the maglev vehicle, and achieves the effects of easy assembly and maintenance, simplified structure and manufacturing and assembly process, and convenient installation, assembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

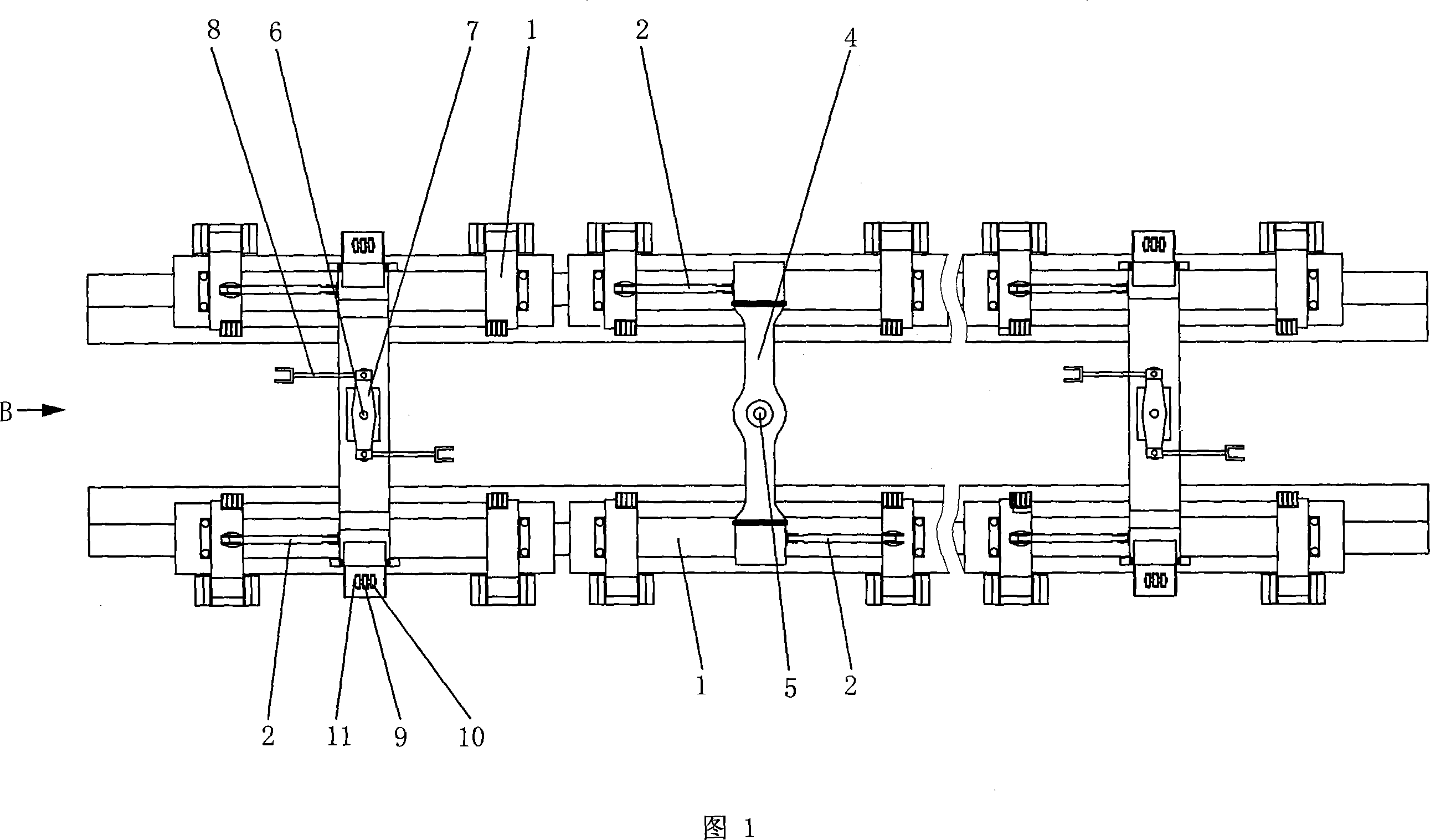

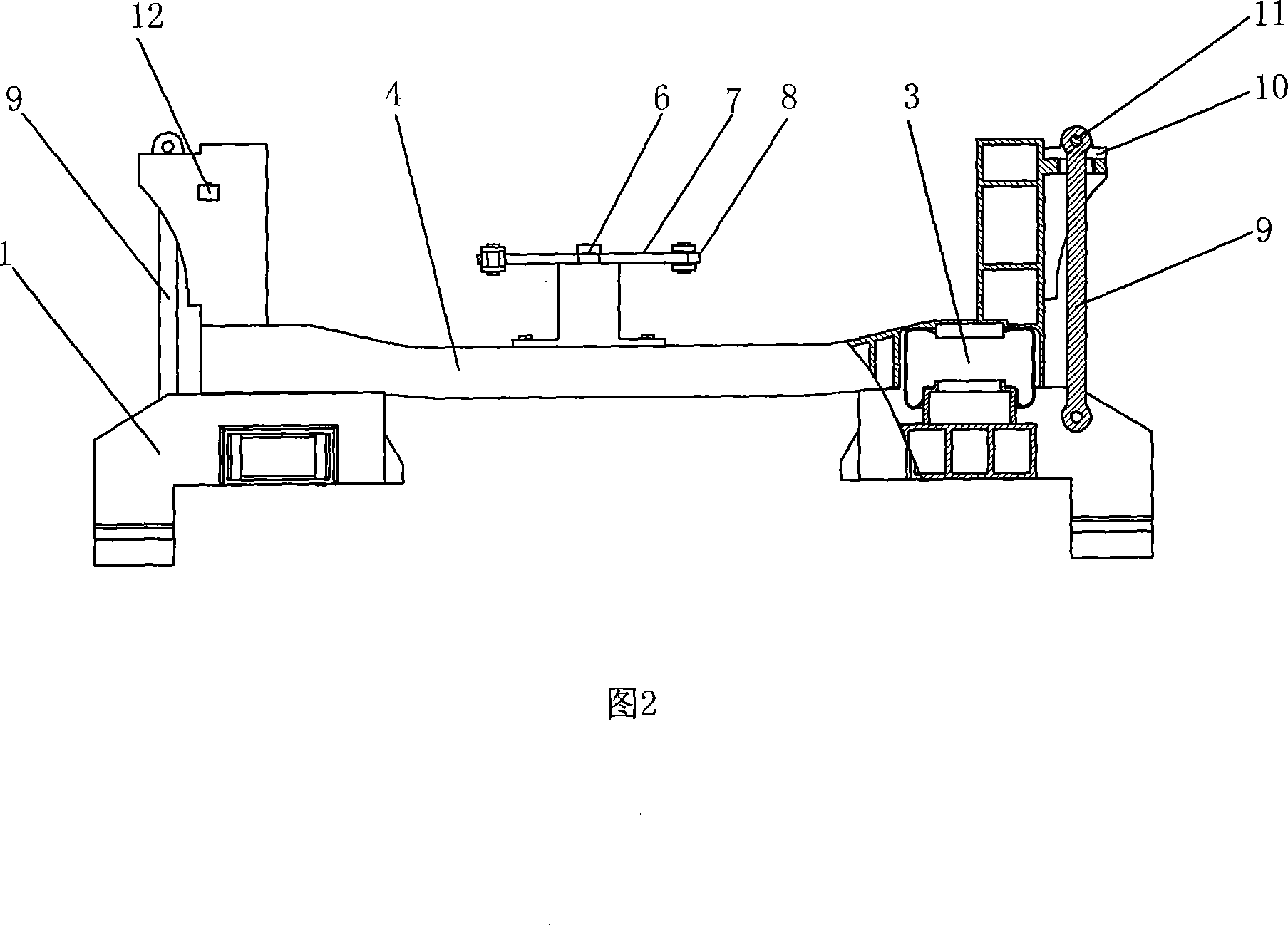

[0025] Fig. 1, 2 shows, and a kind of specific embodiment of the present invention is:

[0026] A running mechanism of a medium-low speed maglev train with an air spring in the middle. The running mechanism of each car includes at least one mobile running module that can be displaced and rotated relative to the car body and two that can rotate but cannot rotate with the car body. The fixed-point travel module for lateral displacement, mobile or fixed-point travel module includes: suspension frame 1, two drawbars 2 and air spring 3 on the suspension frame 1, of which:

[0027] a. The composition of the mobile walking module is as follows: a bolster 4 is arranged horizontally at the middle position of the suspension frame 1, and the two ends of the bolster 4 are fixedly supported on the suspension frame 1 through the air spring 3 below it; The center is connected with a traction block 7 through a connecting pin 6, and the two ends of the traction block 7 are respectively hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com