Manufacturing method of metal rubber shock pad

A production method and technology of metal rubber, applied to the online network, other home appliances, home appliances, etc., can solve the problems of complex manufacturing process of metal rubber shock absorbers, inability to realize automatic assembly line production, and difficulty in providing demanded products on time, to achieve The effect of simplifying the preparation process, simplifying the manufacture and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

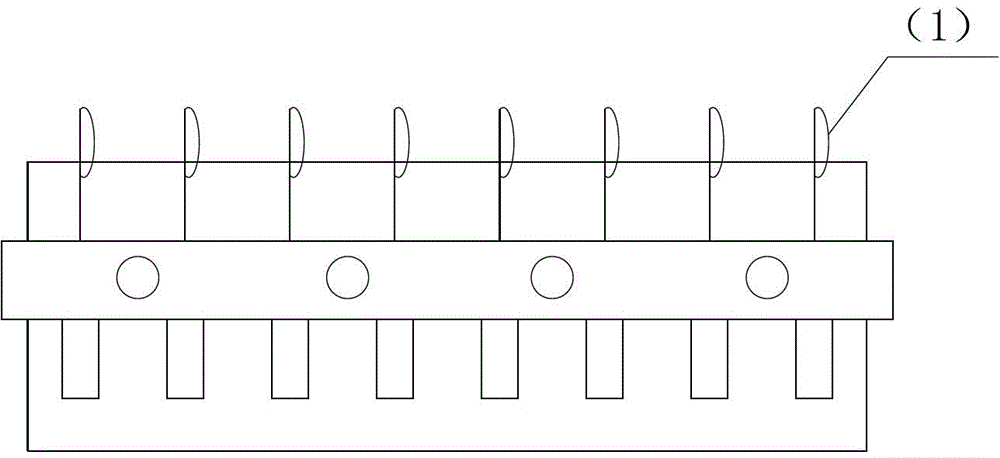

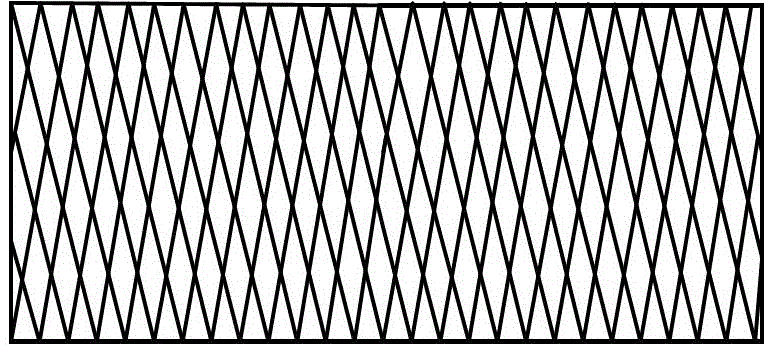

[0023] Specific implementation mode one: combine figure 1 As shown in the figure, the metal wire is woven through the crochet needle (1) of the knitting machine, and the continuous unit coils are strung together in one direction, and finally an infinitely long wire mesh can be formed. Then cut the wire mesh in the length direction so that its quality reaches the expected quality. The cut wire mesh is rolled and wound to form a blank, and finally stamped and formed by a die. During the weaving process, the caliber width of the weaving machine determines the width of the wire mesh, and ultimately affects the height range of the metal rubber shock absorber.

specific Embodiment approach 2

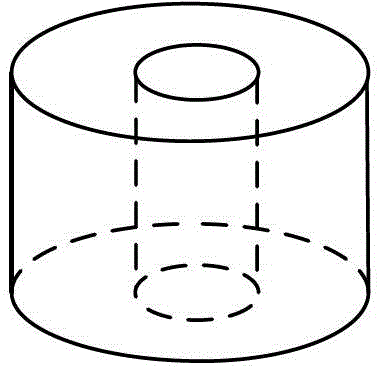

[0024] Specific implementation mode two: combination figure 2 As shown, the cross-section of the metal rubber shock absorber in this embodiment is circular and has holes, and the metal wires used to make the shock absorber are stainless steel wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com