Metal-rubber composite gland bush molding die and molding method thereof

A technology for compounding gaskets and forming molds, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of difficult sealing, difficulty in designing a mold taking space, and difficulty in taking product molds, and achieves simple structure and low cost. , the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

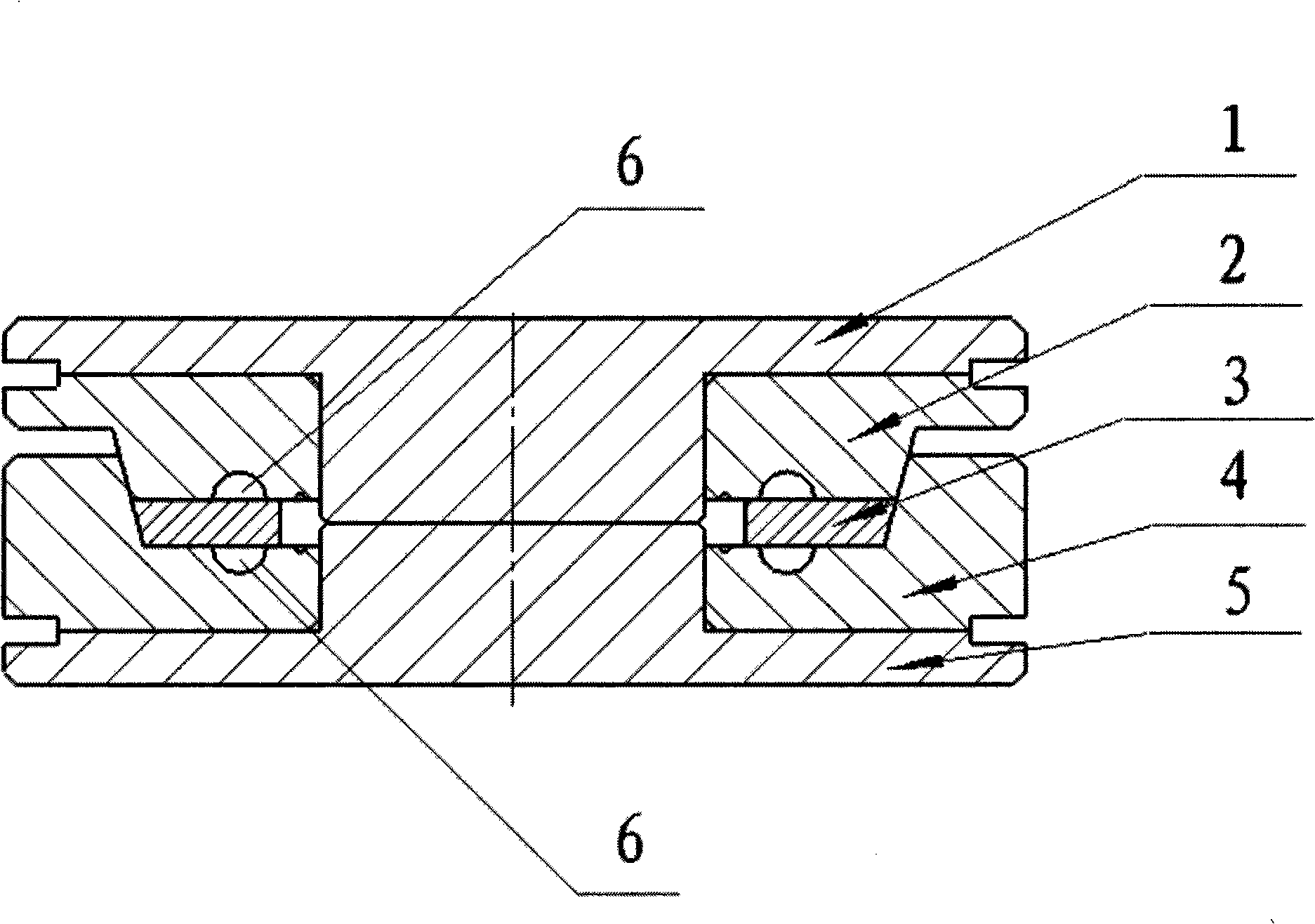

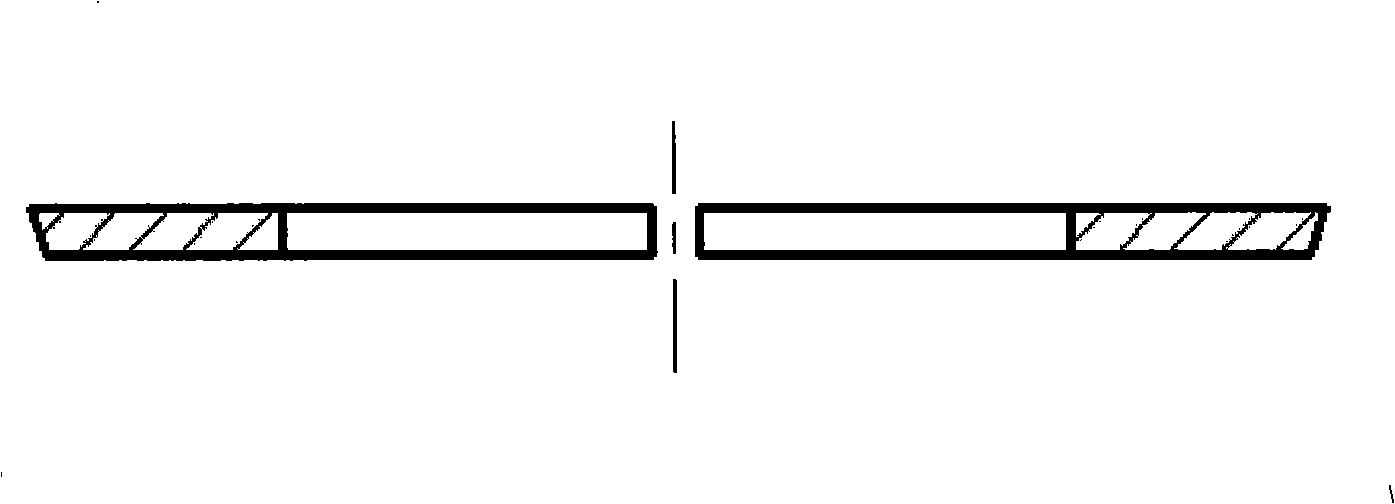

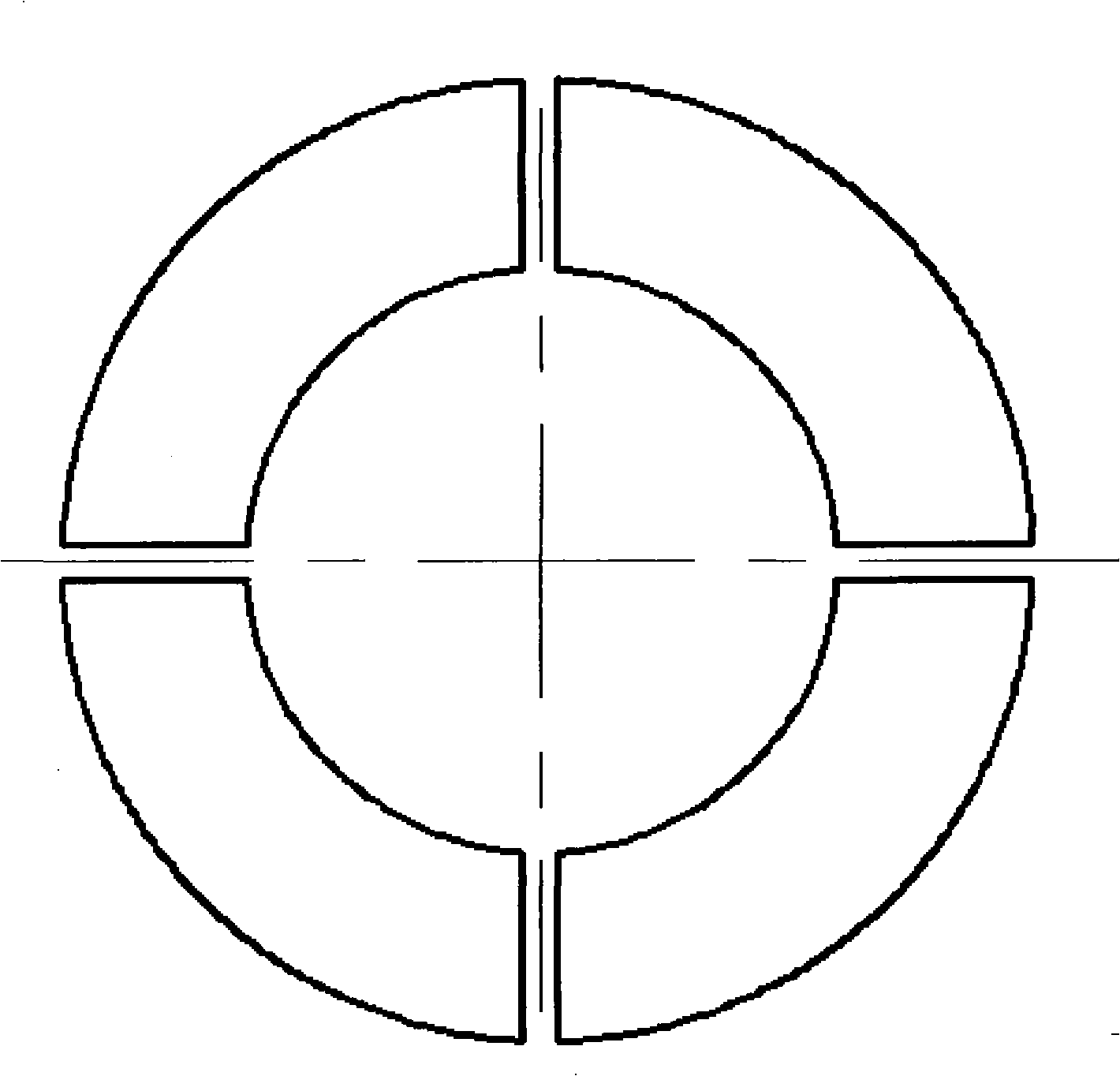

[0030] Such as figure 1 As shown, the metal-rubber composite gasket forming mold includes an upper core plate 1, an upper platen 2, a lower core plate 5, a positioning gasket 3 and a lower platen 4, and the central cylindrical section of the upper core plate 1 is installed in the center hole of the upper platen 2 Inside, the central cylindrical section of the lower core plate 5 is installed in the center hole of the lower pressing plate 4, and a positioning washer 3 is installed between the upper pressing plate 2 and the lower pressing plate 4.

[0031] The metal skeleton 12 of the metal-rubber composite gasket is placed in the cavity formed by the upper core plate 1, the upper platen 2, the lower platen 4, the positioning gasket 3 and the lower core plate 5, the positioning gasket 3, the upper platen 2 and the lower platen The mating surfaces among the 4 are at an inclination angle of 15° to 20°, which is convenient for disassembly.

[0032] During the vulcanization molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com