Internal groove self-lubricating dynamic-static pressure coupling air-float bearing

An air bearing, self-lubricating technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of damaged bearings, high requirements on wear resistance, difficult material and process performance, etc., to improve wear resistance. , broaden the scope, improve the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

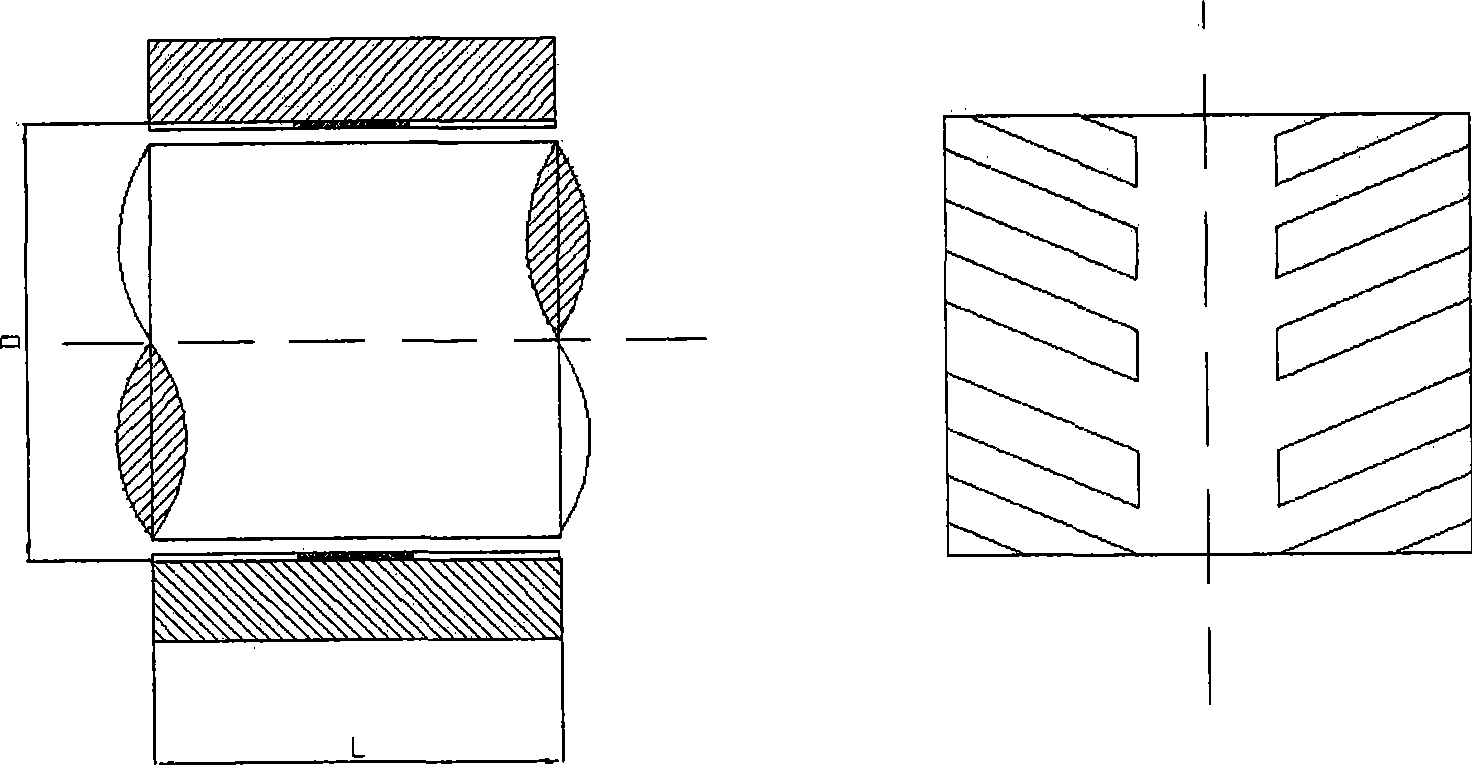

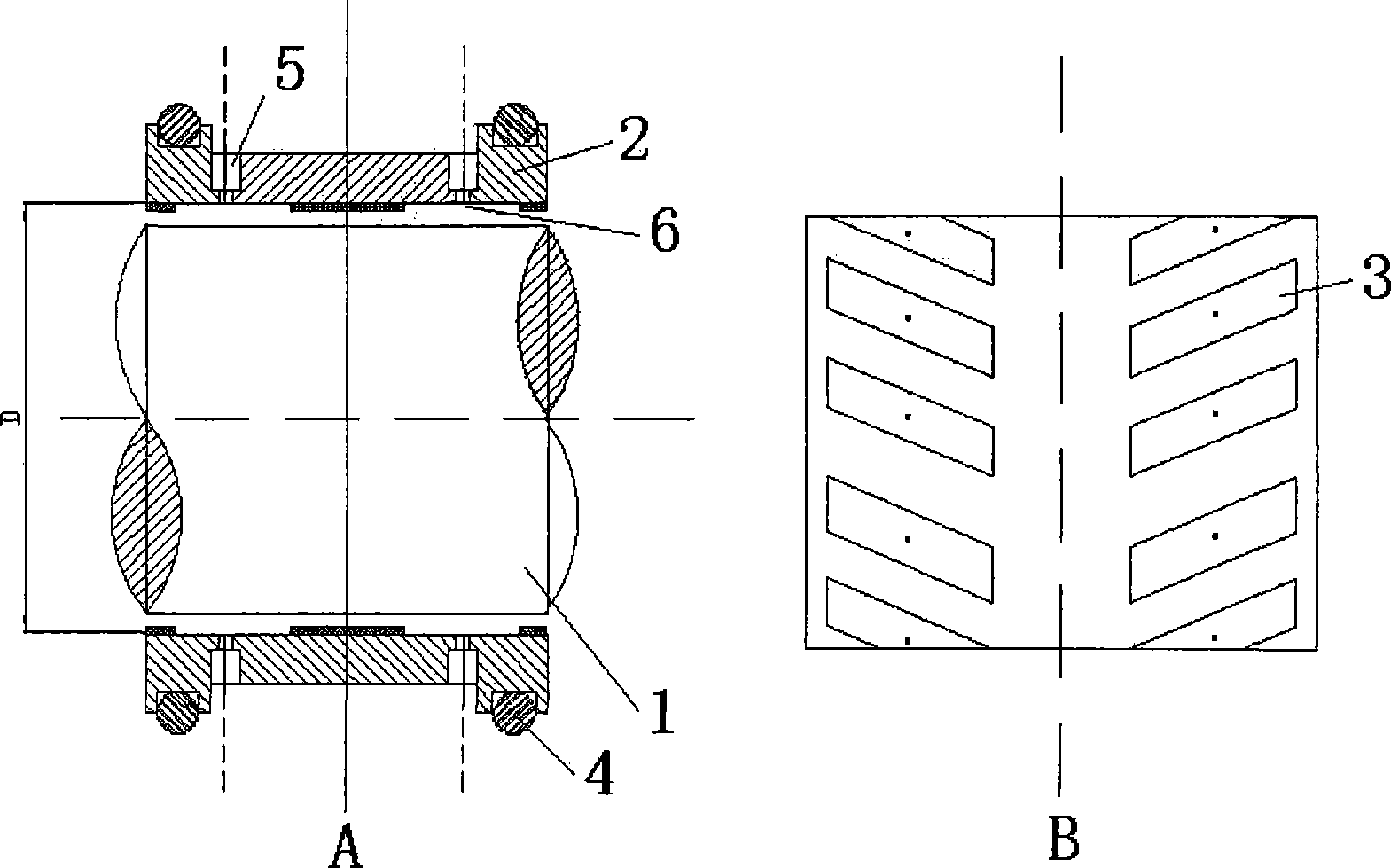

[0033] 1. Selection of air bearing body 2: According to the air bearing application temperature T<200°C and the working medium is air under ambient pressure, carbon graphite with wear resistance, high temperature resistance and self-lubricating properties is selected as the air bearing body 2 Material.

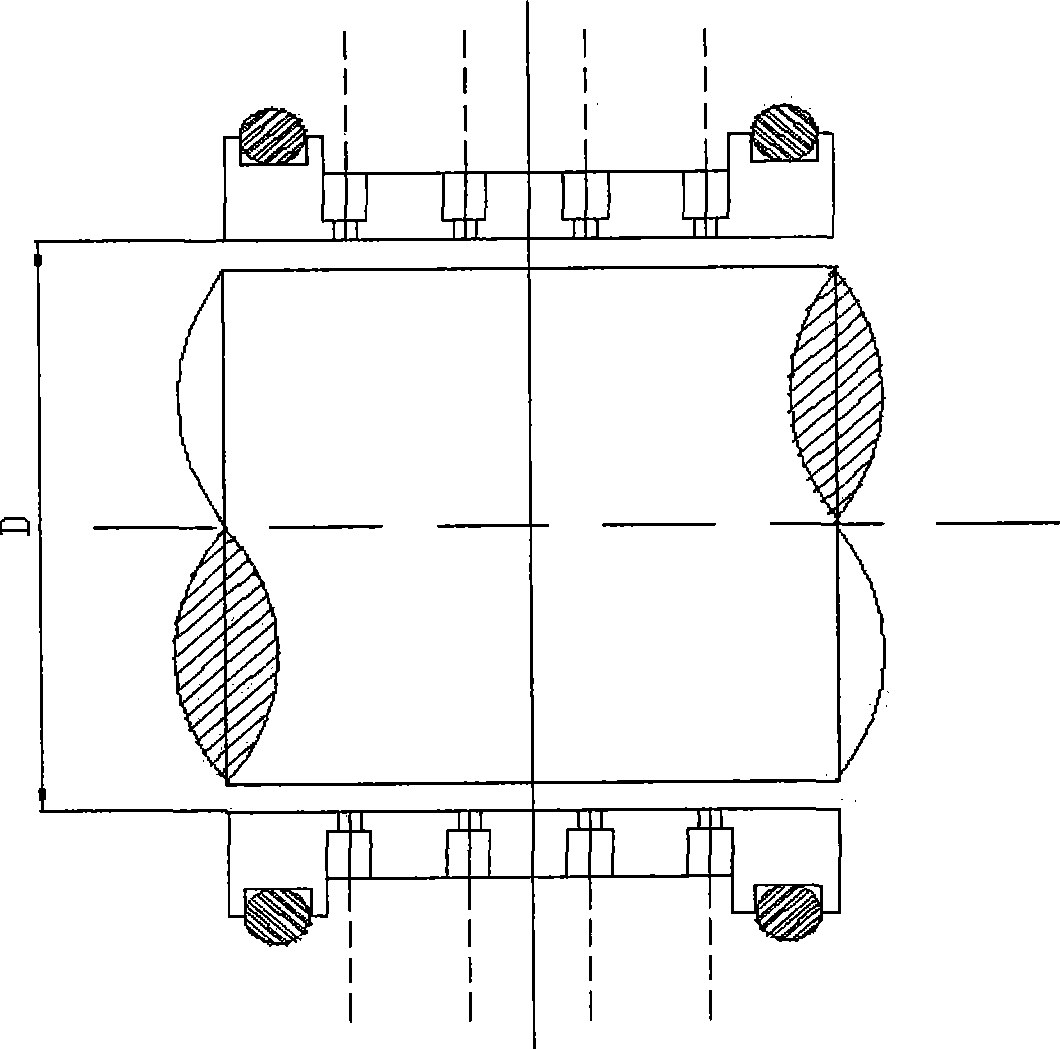

[0034] 2. The dynamic and static pressure structure design of the air bearing: according to the static load borne by the air bearing is 3 kg, and the working speed of the rotor is 38000rpm, it is determined that the double-row nozzle 6 throttles the tangential air supply hole 5 and the inner surface to set a figure-eight pressurized flow Structural design of track groove 3.

[0035] 3. The structural design of the pneumatic bearing body: according to the load nature and stability requirements of the fluid dynamic sealing ring, the elastic rubber ring is used as the vibration damping elastic ring 4 to complete the design of the structure, strength and motion stability of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com