Automobile suspension mechanism

A technology of automobile suspension and metal rubber, which is applied in the direction of power plant, vehicle parts, jet propulsion device, etc., can solve the problem that the stiffness change curve of rubber parts is difficult to accurately match the actual driving conditions, which affects the quality of the whole vehicle and the service life of parts and components. Vehicle vibration and noise reduction performance and other issues, to achieve the effect of good elastic performance, strong compression and tensile resistance, and good damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing of description, the present invention will be further described.

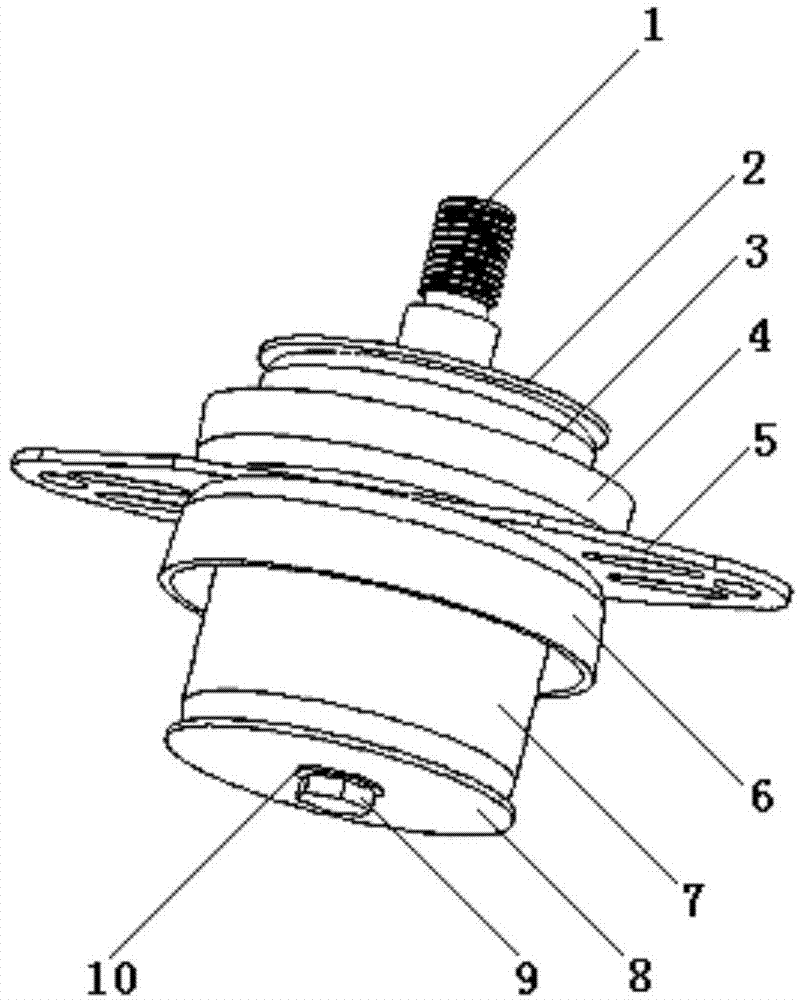

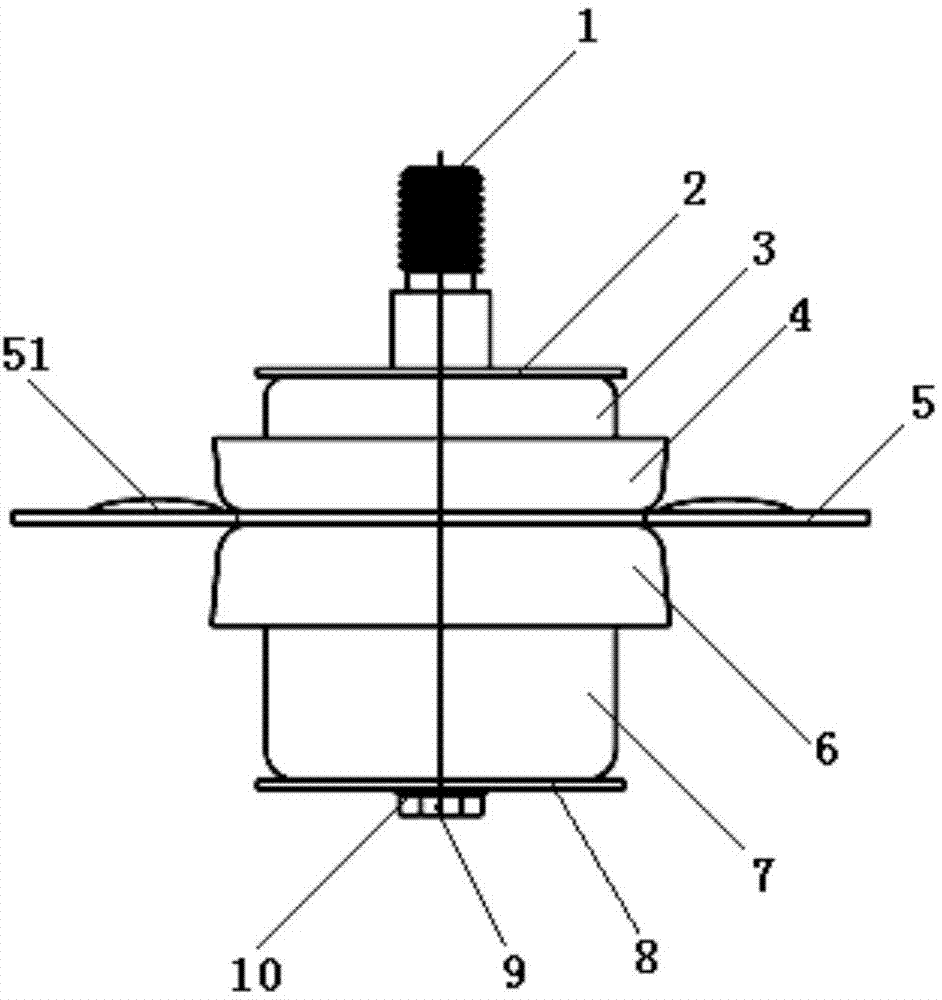

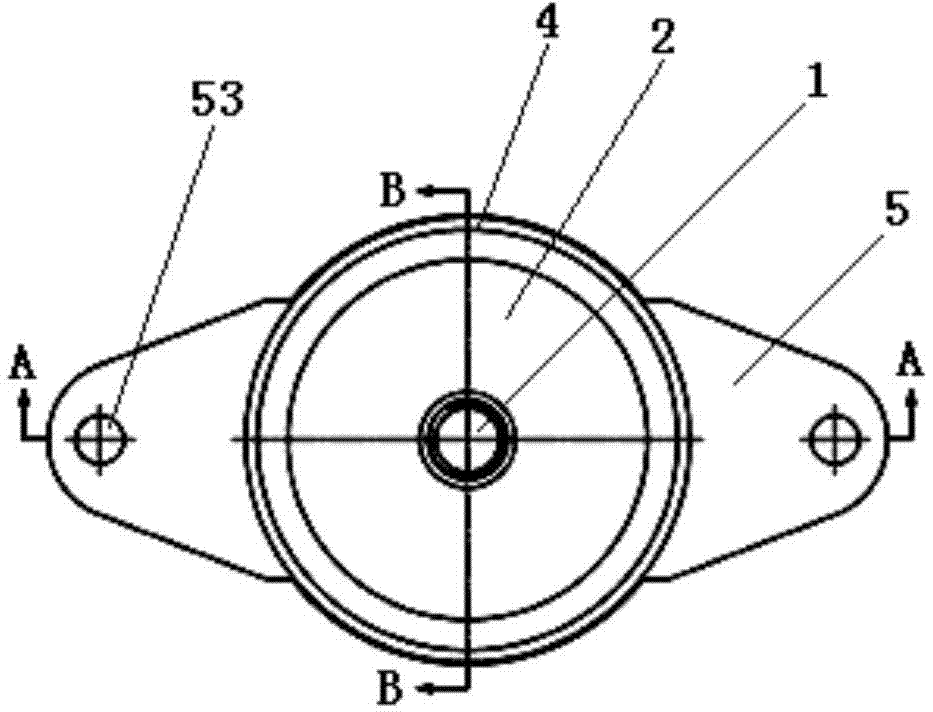

[0034] like Figure 1 to Figure 12 As shown, an automobile suspension mechanism includes a connecting screw 1, which is sequentially set on the upper cover plate 2 of the connecting screw 1, the upper metal rubber spring 3, the upper mounting seat 4, the middle mounting plate 5, the lower mounting seat 6, the lower metal Rubber spring 7 and lower cover plate 8; The rod body of described connecting screw rod 1 is provided with mounting portion 11, shoulder 12 and suit portion 13 successively, and described lower cover plate 8 is connected with the end of set portion 13 by fastener; The end of the sleeve portion 13 is provided with an internal thread 130 , the fastener is a mounting bolt 9 , and the lower cover plate 8 is fastened to the end of the sleeve portion 13 by screwing the mounting bolt 9 into the internal thread 130 .

[0035] There is also a conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com