Journal spring buffering method for railbound vehicle bogie and journal spring

A technology for axlebox springs and rail vehicles, which is applied in the vibration damping method of truck axlebox springs and the field of axlebox springs to achieve the effects of weight reduction, simplified structure, and high product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

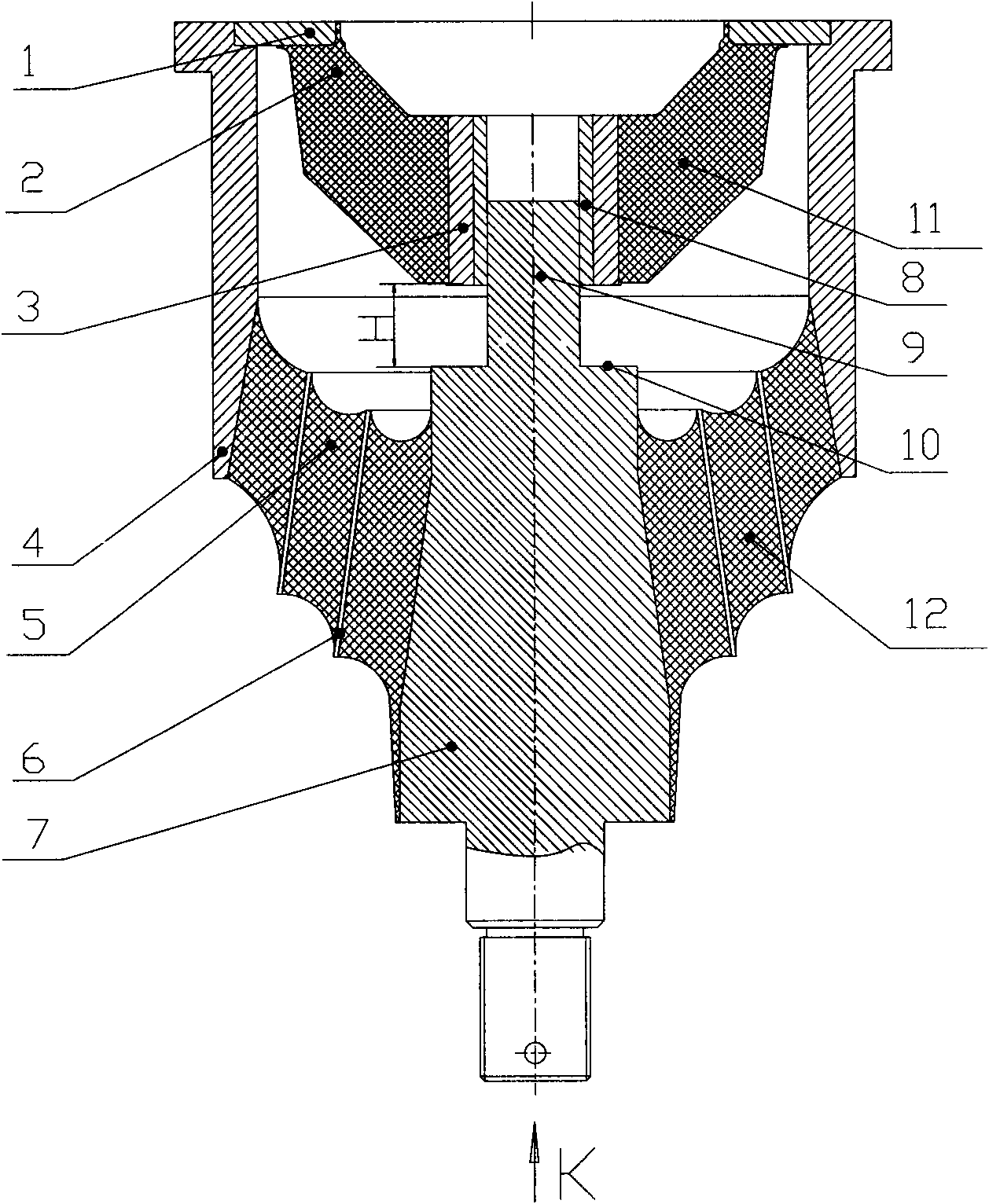

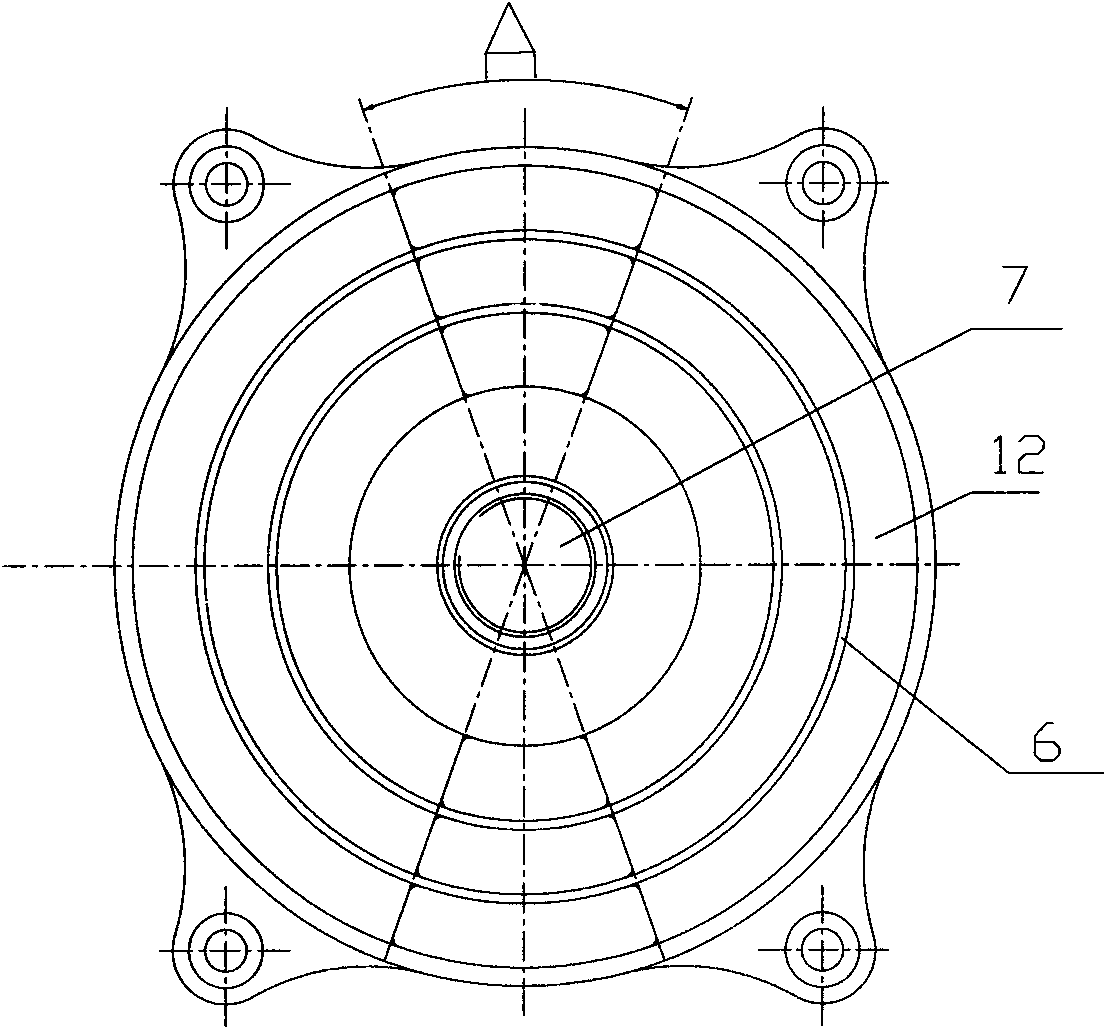

[0014] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

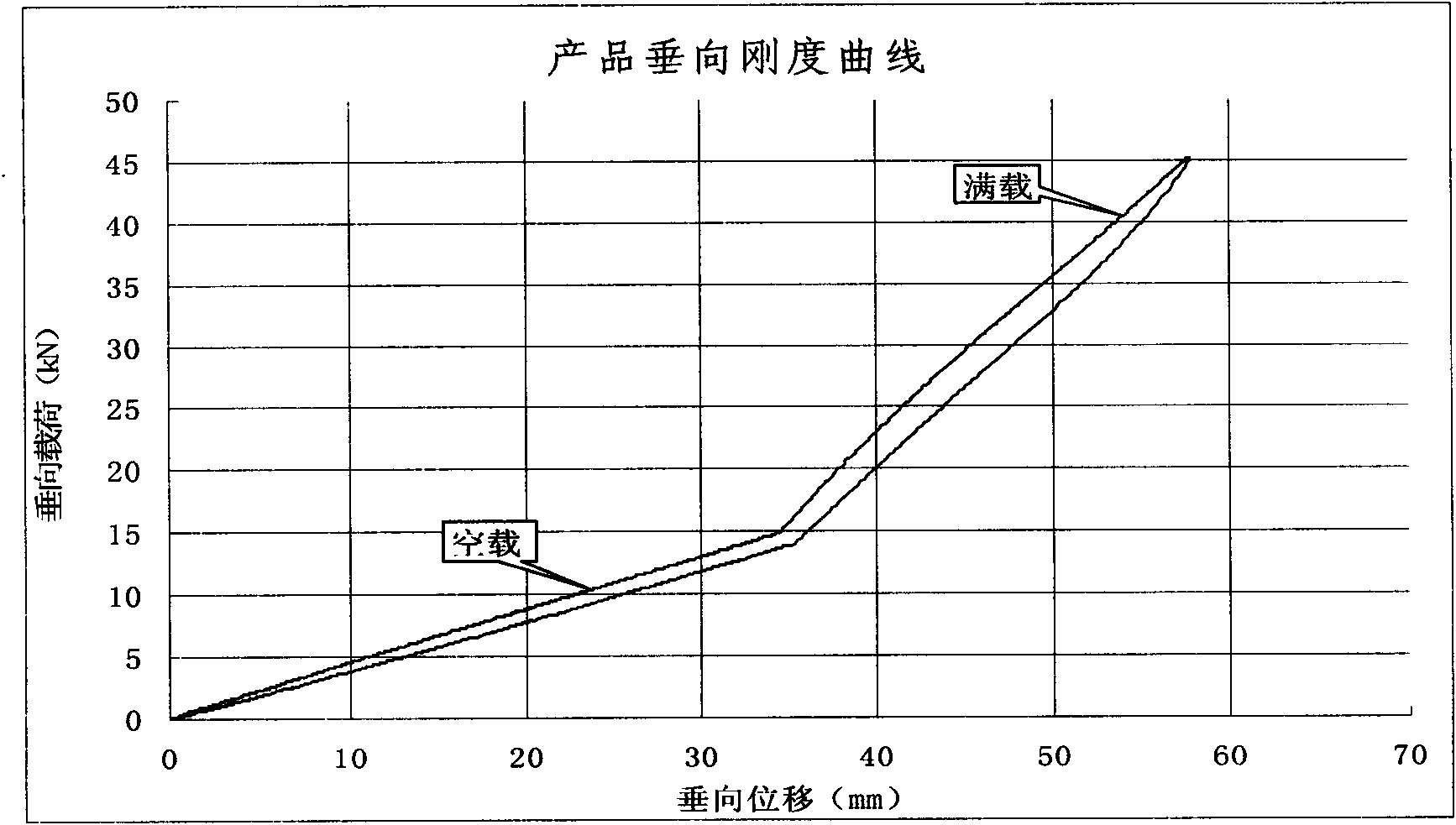

[0015] As can be seen from the accompanying drawings, the present invention is a truck axle box spring damping method for rail vehicle bogies, which adopts a two-stage damping method; the axle box spring is a composite axle box formed by a combination of a main spring and an auxiliary spring Spring; the main spring still adopts the current metal-rubber composite conical spring; on the main spring, there is a shear-type conical frustum rubber stack auxiliary spring. The auxiliary spring of the cone-truncated rubber stack with shearing force is located on the main spring, and absorbs the vibration by bearing the shearing force when the main spring is compressed and contacts it. The damping of the axle box spring is divided into two stages of damping. In the vertical direction, the rigidity series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com