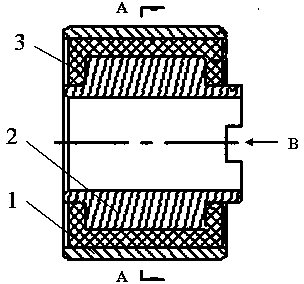

Splined metal-rubber composite spherical hinge and manufacturing and assembling method thereof

A technology of metal rubber and composite ball joints, which is applied to springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, to improve product quality, improve adhesion, and buffer instantaneous impact loads and torsional loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

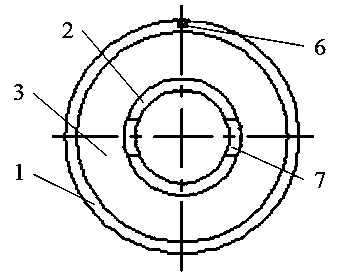

[0025] Embodiment 2, the difference from Embodiment 1 is that the metal outer sleeve 11 is provided with a positioning notch 1 66, and the metal inner sleeve 22 is provided with a positioning notch 2 77, which is used for mold positioning to ensure that the sawtooth and sawtooth are aligned during the vulcanization process. The correct positional relationship can be maintained to achieve the required clockwise and counterclockwise torsional stiffness.

Embodiment 3

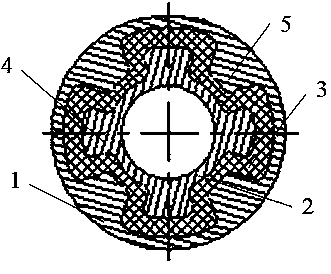

[0026] Embodiment 3 is different from Embodiments 1 and 2 in that the number of internal spline serrations 5 is three, and the number of external spline serrations 4 is three.

Embodiment 4

[0027] Embodiment 4 is different from the above embodiments in that the number of internal spline saw teeth 5 is eight, and the number of external spline saw teeth 4 is eight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com