Metal rubber work blank laying device

A metal rubber and laying device technology, which is applied in the field of metal processing, can solve the problems of difficulty in ensuring the consistency of product size and performance, low production efficiency, and high labor intensity, so as to solve the problem of blank forming, improve production efficiency, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

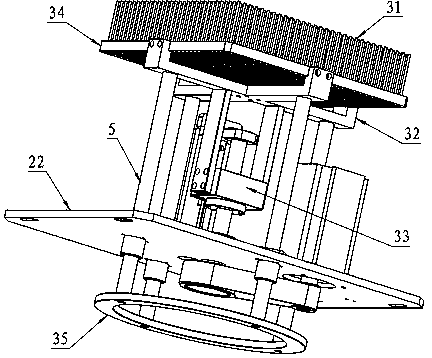

[0027] The metal rubber blank laying device provided by the present invention adopts the PMAC multi-axis control technology to realize the precise stretching of dense-turn metal wire spiral coiling with fixed pitch, 3D three-dimensional weaving trajectory planning to the fully automatic and precise control of 3D three-dimensional laying blanks, and solves the problem Blank forming of large-sized metal-rubber sheet products and metal-rubber products with complex configurations.

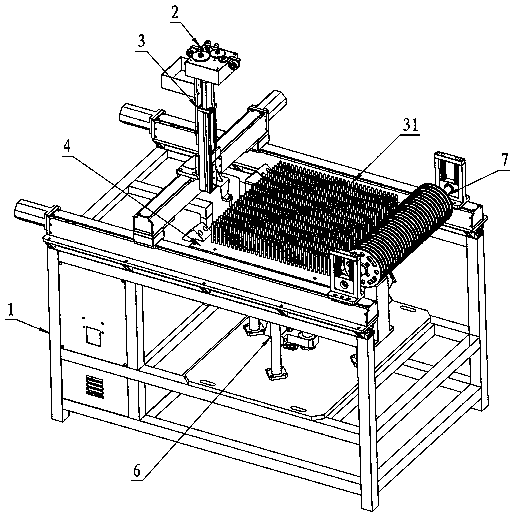

[0028] The metal rubber blank laying device is mainly composed of eight parts: frame 1, fixed pitch stretching mechanism 2, laying mechanism 3, laying plate 4, shaping plate 34, shaping plate lifting mechanism 6, rolling mechanism 7 and control system.

[0029] The frame 1 is a welded assembly of square pipes and angle steels, and is used to install and support various components of the equipment.

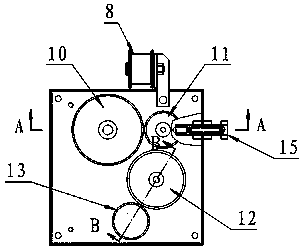

[0030] The fixed-pitch stretching mechanism 2 is used for constant-pitch stretching of the dense-turn me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com