Scrap-leakage-proof metal-rubber damper suitable for in-orbit application of spacecraft

A metal rubber and damper technology, which is applied in the direction of the guidance device, shock absorber and shock absorber of aerospace vehicles, can solve the problems of debris, pollution, wire breakage, etc., to prevent pollution, optimize dynamic characteristics, Adjust the effect of optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

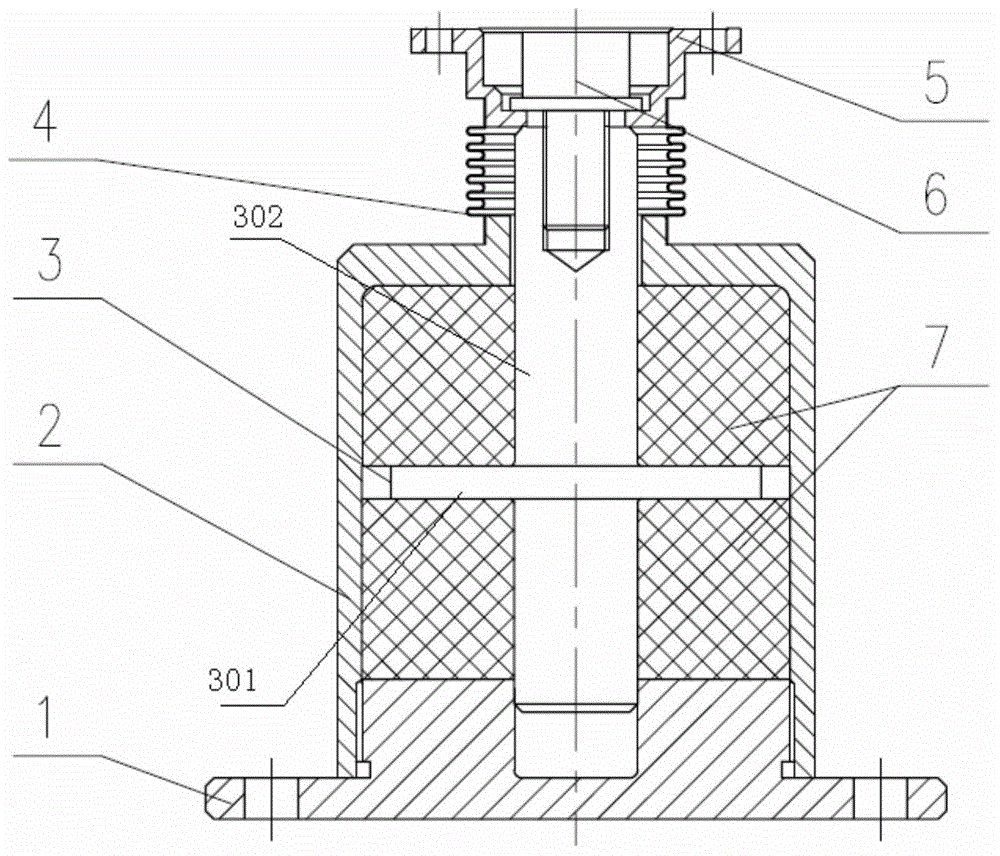

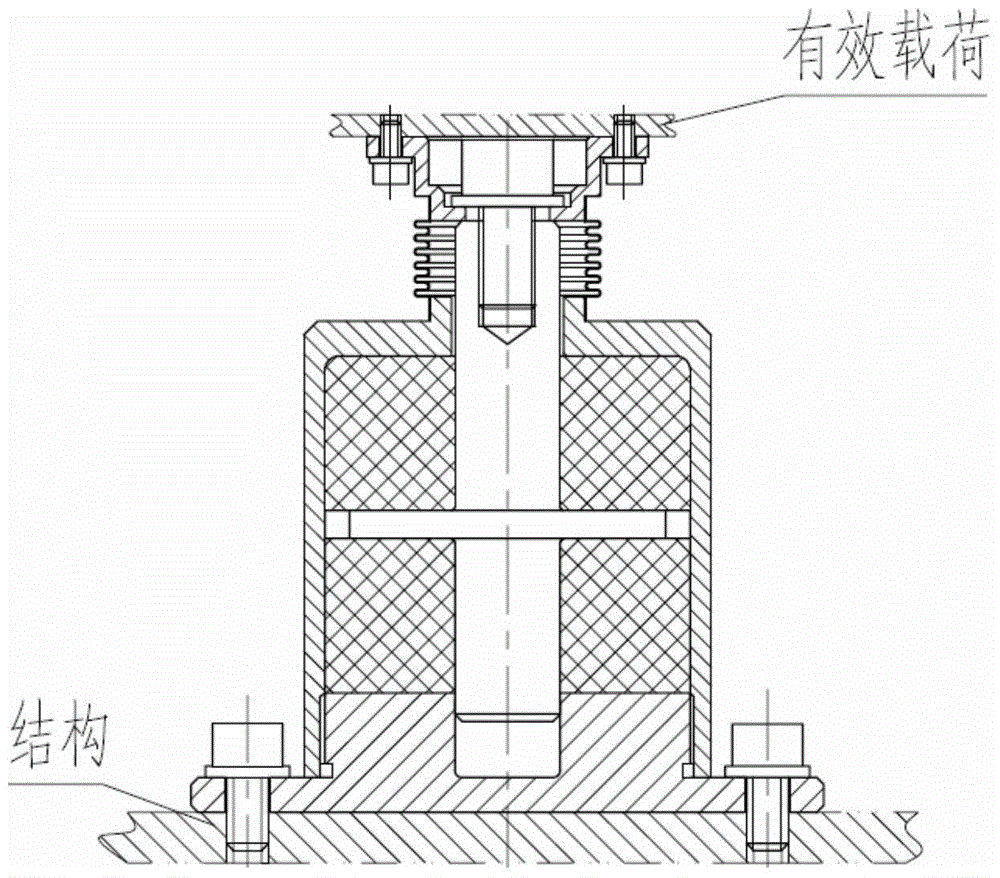

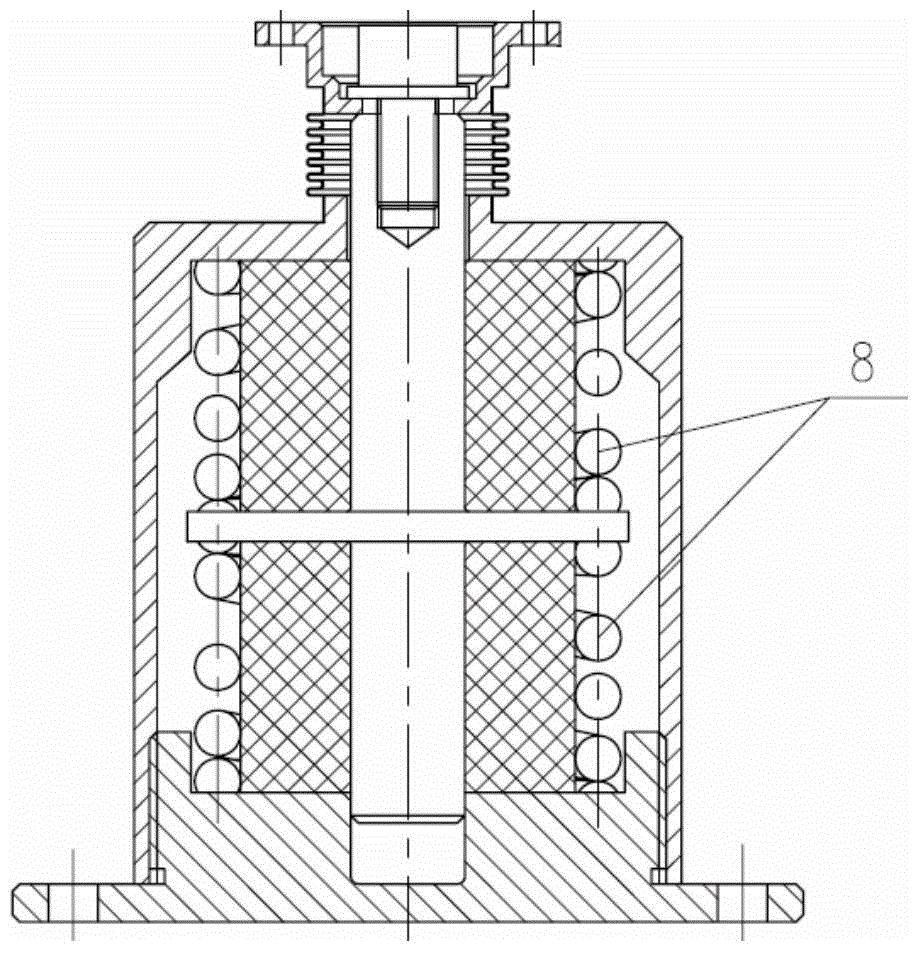

[0020] The invention provides a metal rubber damper suitable for on-orbit application of spacecraft, such as figure 1 As shown, it includes a metal rubber pressing plate 1, a casing 2, a mandrel 3, a bellows 4, a bellows flange 5, a screw 6 and a metal rubber element 7.

[0021] The shell 2 is a stepped hollow cylinder; the mandrel 3 is located in the large cylindrical section of the shell 2, including the horizontal mandrel 301 and the vertical mandrel 302. The horizontal mandrel 301 and the vertical mandrel 302 are formed by integrated processing. Both the shaft 301 and the vertical mandrel 302 are solid cylinders, the metal rubber element 7 is located in the large cylindrical section of the shell 2, and the metal rubber element 7 is two hollow cylinders, which are respectively located on the upper and lower sides of the horizontal mandrel 301, and Sleeve on the outer circumference of the vertical mandrel 302; the vertical mandrel 302 is inserted into the small cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com