Single-pipe double-line maglev traffic vacuum pipeline with sealing door

A technology of vacuum pipelines and sealing doors, which is applied in tracks, roads, tunnel systems, etc., can solve the problems of reducing the service life of pipelines, destroying the structural strength of pipelines, and increasing costs, so as to improve the accuracy and reliability, improve the scope of application, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

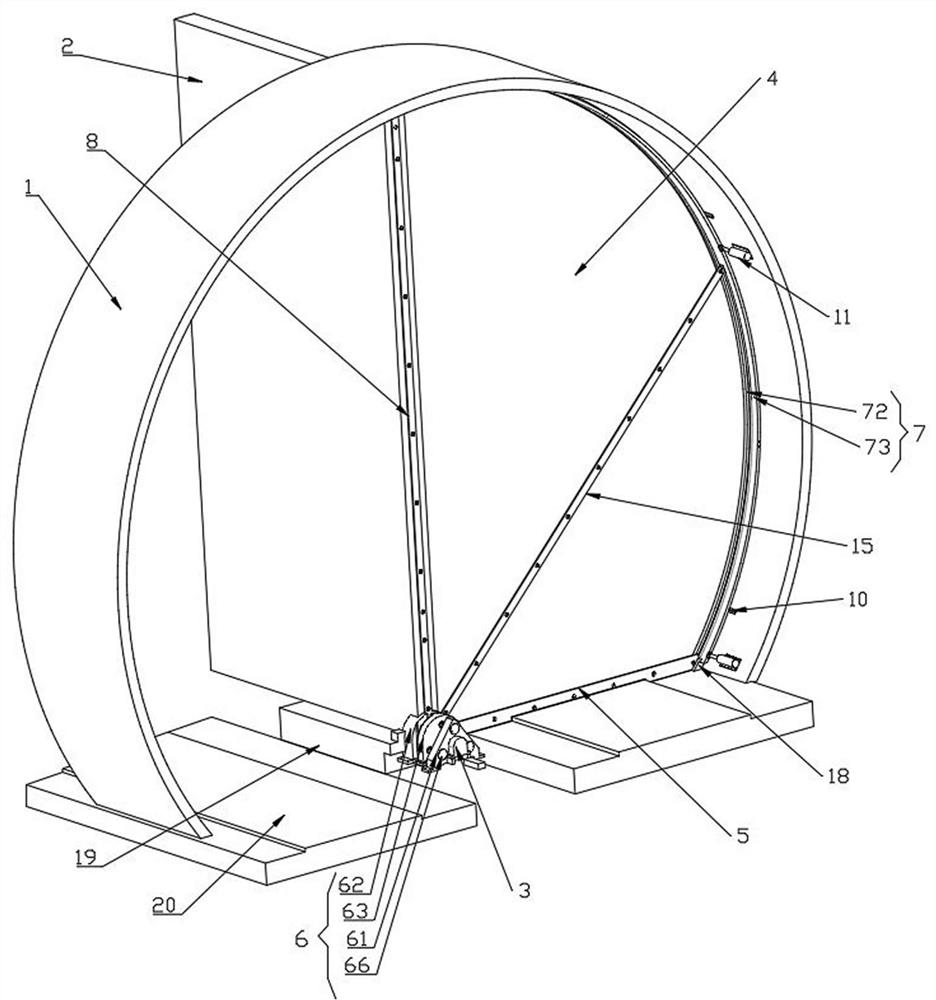

[0064] Such as Figure 1 to Figure 17 As shown, this embodiment provides a single-pipe double-line maglev traffic vacuum pipeline with a sealed door, including a vacuum pipeline 1, a windshield 2 is fixedly arranged in the middle of the vacuum pipeline 1, and a windshield 2 is fixed in the middle of the vacuum pipeline 1. There is an embankment 19, the bottom of the windshield 2 is fixedly connected with the embankment 19, and its top is completely attached to the vacuum pipeline 1, so that the vacuum pipeline 1 is divided into two independent traffic passages by the windshield 2, and the bottom of the two traffic passages A corresponding permanent magnet track 20 is provided;

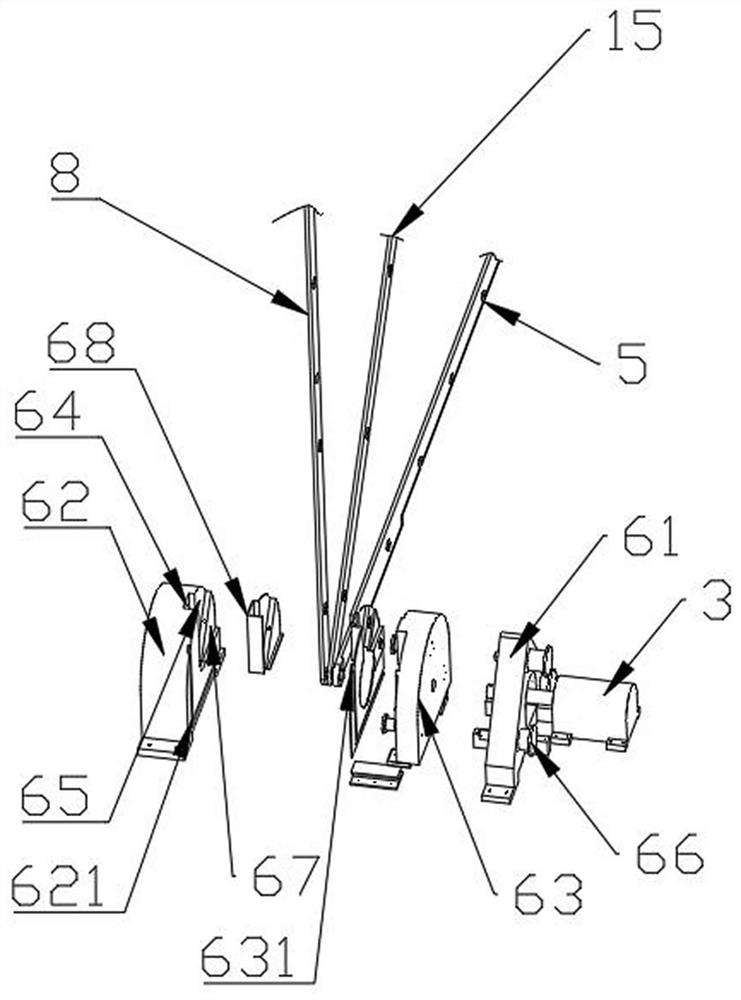

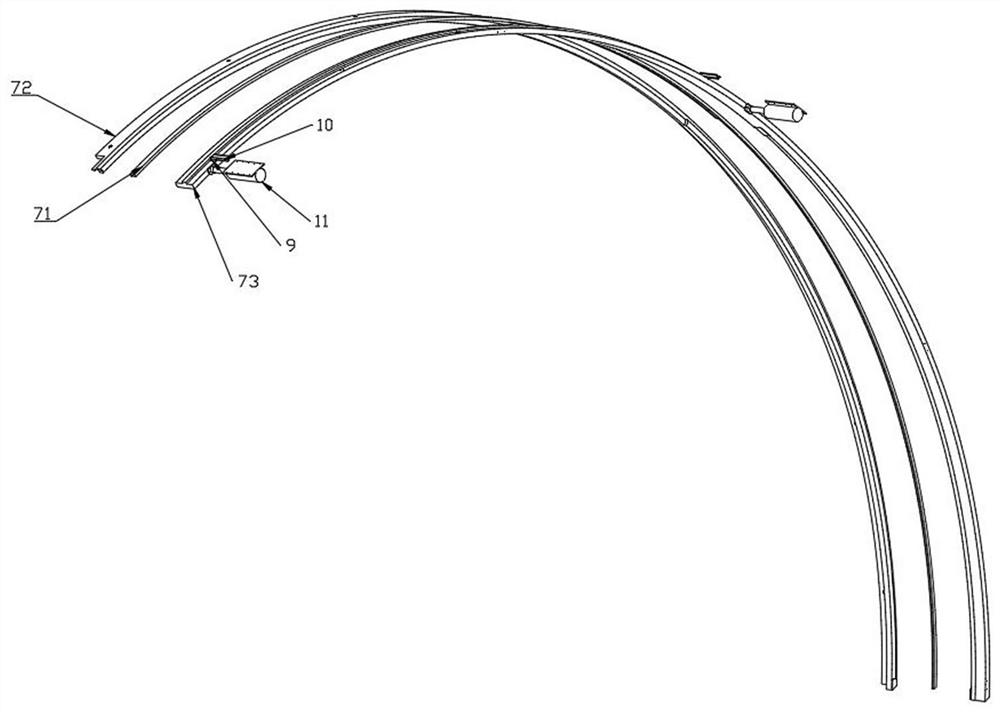

[0065] The vacuum pipeline 1 is also provided with a driving motor 3, a sealing fan 4, a swing rod 5, a first clamping sealing device 6 and a second clamping sealing device 7, and the first clamping sealing device 6 includes a fixed box 62 , the movable clamping box 63 and the support frame 61, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com