Floor drain device

A floor drain and knob technology, applied in water supply devices, waterway systems, buildings, etc., can solve the problems of not considering the anti-blocking or anti-blocking effect of water pipes, not having the ability to control water flow/break, and drainage pipe blockage, etc., to achieve simple connection methods , wide application range, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

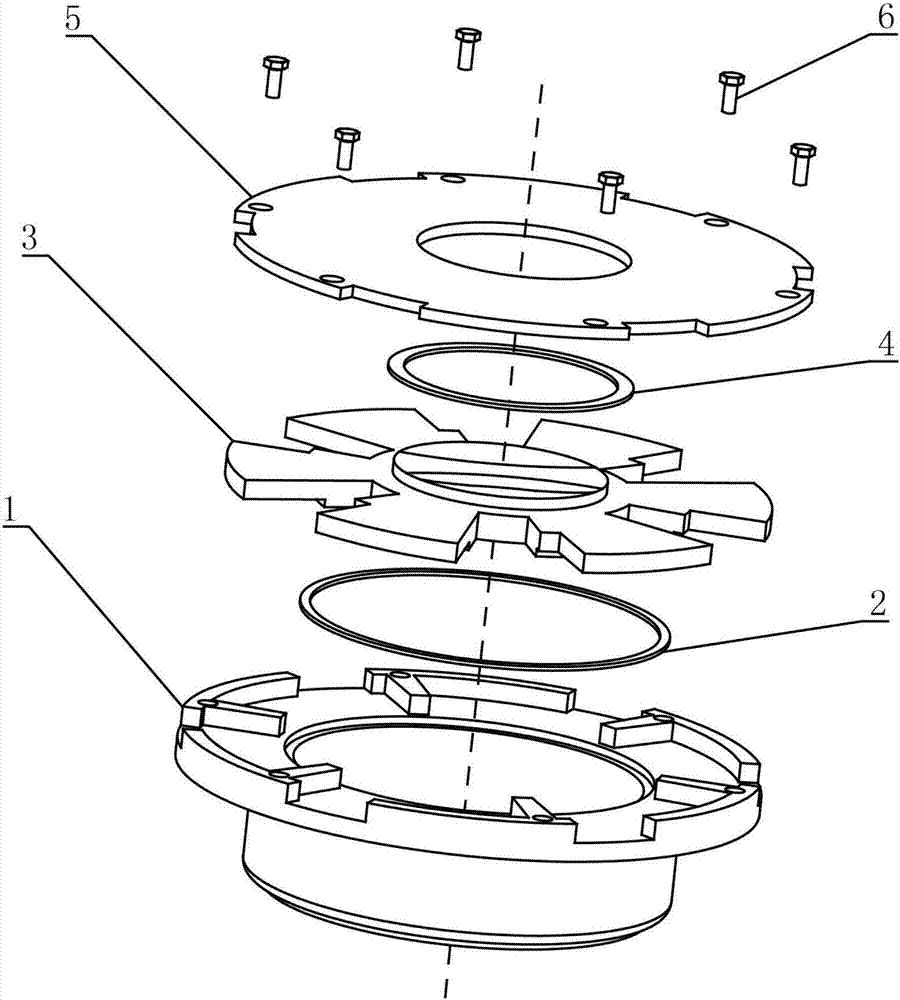

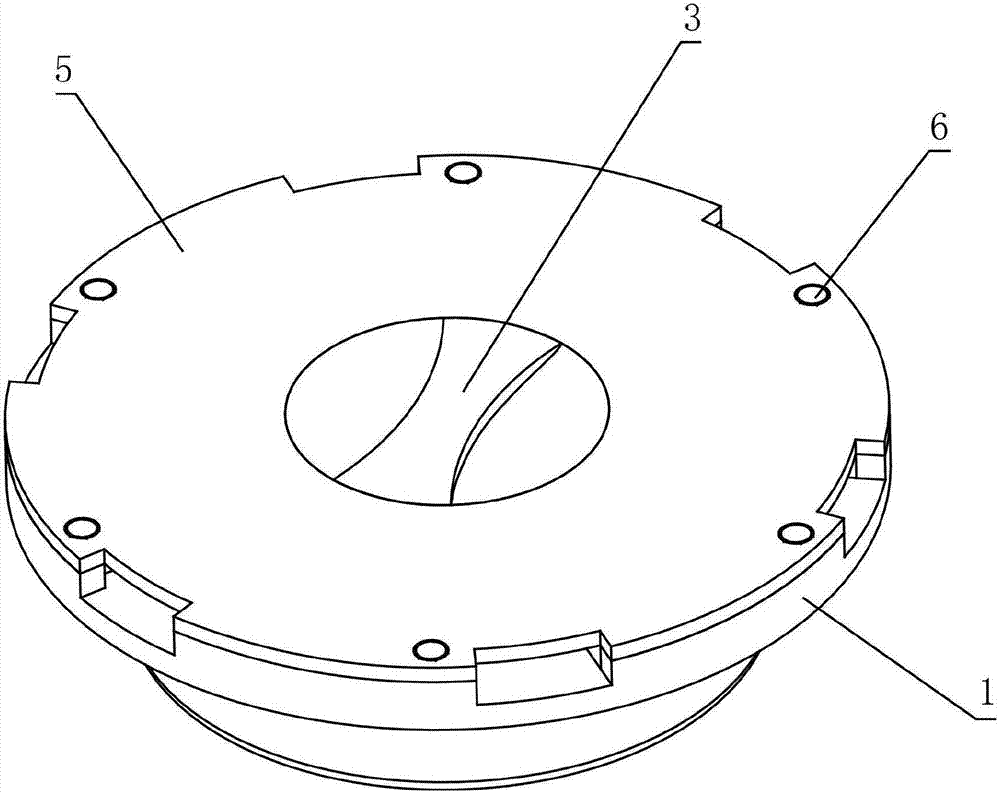

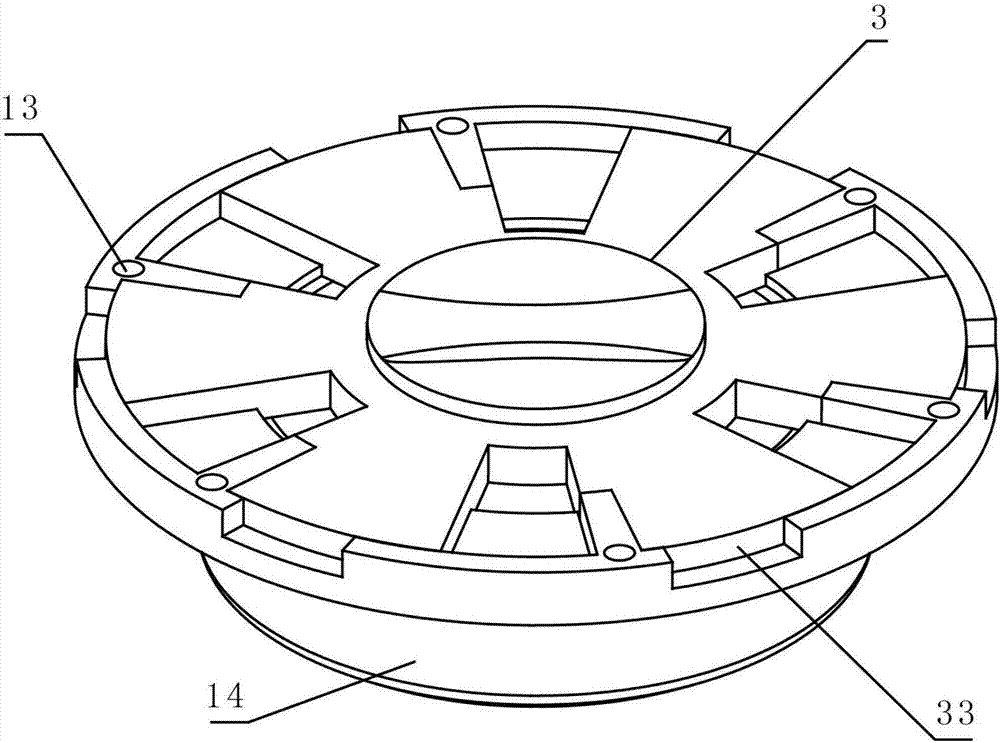

[0039] see figure 1 , figure 2 , image 3 , a floor drain device is provided in this embodiment, which includes a base 1, a knob 3, a top cover 5, and a bolt 6. The inner wall of the base 1 is provided with a first step 11, and one surface perpendicular to the axis A number of baffles 12 are provided, and threaded holes 13 are provided on the baffle 12, and a flange 14 is provided on the other surface. The specific structure of the base 1 is as follows: Figure 5 shown;

[0040] One surface of the knob 3 is provided with a handle 31, the other surface is provided with a second step 32, and several blades 33 are provided along the circumferential direction of the axis of the knob 3. The specific structure is as follows: Figure 6 , Figure 7 As shown, the number of the blades 33 is the same as the number of the baffles 12; the first step 11 is matched with the second step 32 to realize the connection between the knob 3 and the base 1, any of the blades 33 can rotate back ...

Embodiment 2

[0046] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that this embodiment also includes a slag trap 7, such as Figure 9 As shown, the slag trap 7 is cylindrical, the side and / or bottom surface of the slag trap 7 is provided with a number of holes 71, and the inner surface of one end of the flange 14 is provided with an internal thread for connecting the The slag separator 7, which can filter the scum or foreign matter in the water flow, further improves the anti-blocking effect of the floor drain device, and can avoid the blockage of the pipeline as much as possible.

[0047] Preferably, in this embodiment, the hole 71 opened on the slag separator 7 is a circular hole, which is convenient for processing and forming, and at the same time facilitates the circulation of water flow.

Embodiment 3

[0049] The main difference between this embodiment 3 and the above-mentioned embodiment 2 is that in this embodiment, the floor drain device is installed on the pipeline with grooves, such as Figure 10 , Figure 11 , Figure 12 as well as Figure 13 shown, where Figure 10 , the knob 3 of the floor drain device is in a closed state, and the water flow on the ground cannot enter the pipeline 8 through the floor drain device, and in Figure 12 Among them, the knob 3 of the floor drain device is in a fully open state, and the water flow on the ground can enter the pipeline 8 through the floor drain device, and the path and direction of the water flow are as follows: Figure 13 As shown by the curve with the arrow in the middle, the water flow entering the floor drain device flows into the pipeline after being further filtered by the slag separator 7, and the filter residue effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com