Double rotational flow premix type metallurgical nozzle

A flow pre-mixing and pre-mixing technology, which is applied in the direction of lighting and heating equipment, furnaces, furnace components, etc., can solve the problem that it is difficult to fully mix the gas with the mineral material, and achieve good fluidity and separation effect, low wear and tear. The effect of improving the thermal efficiency of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

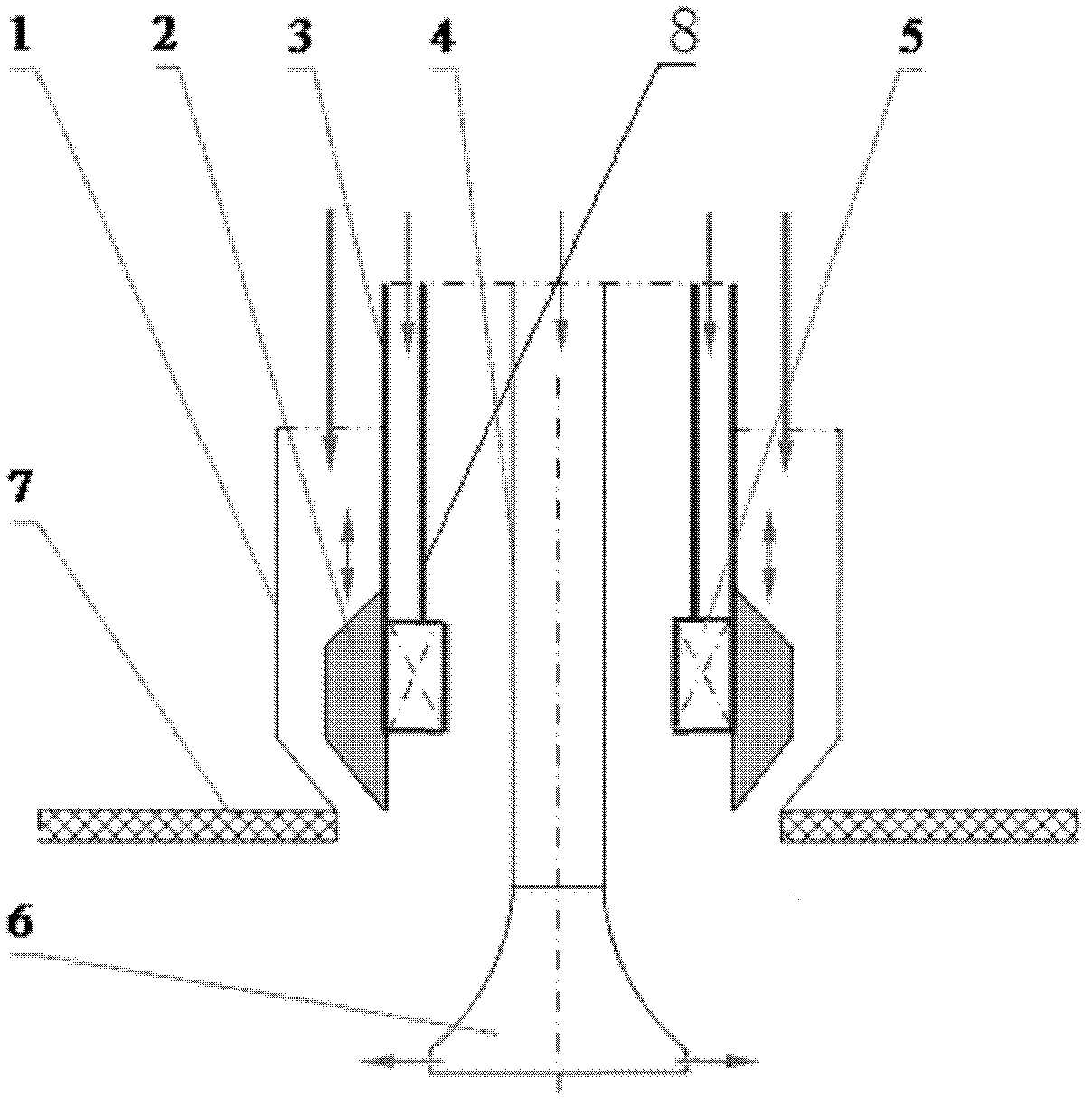

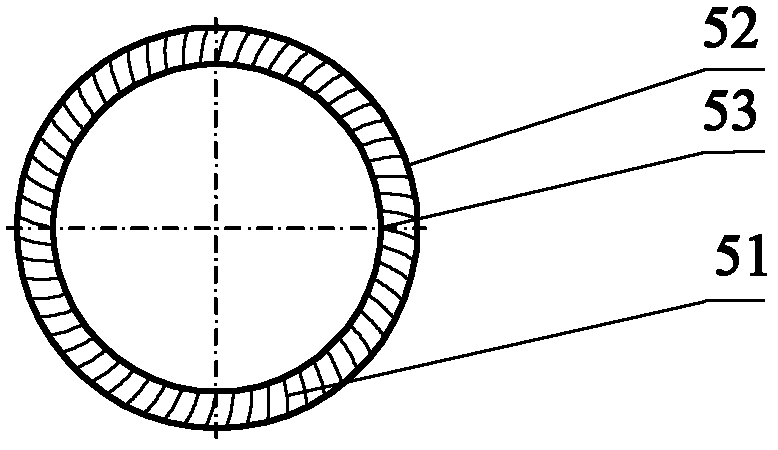

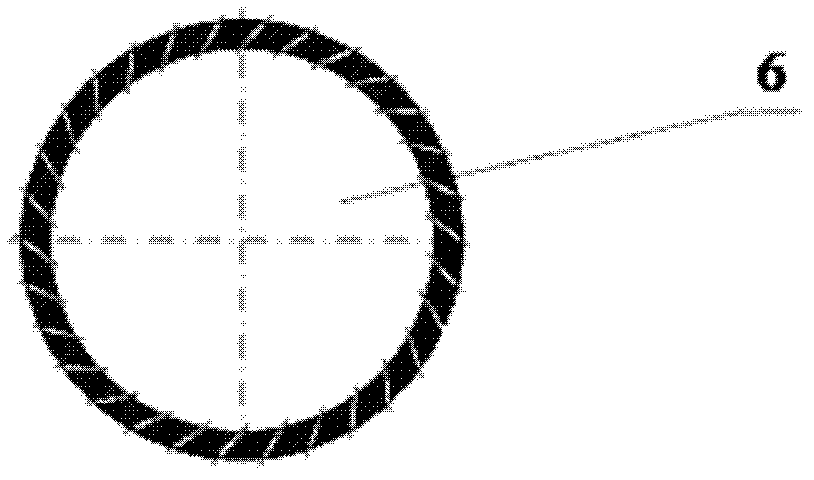

[0017] Such as figure 1 As shown, the double-swirl premixed metallurgical nozzle includes a feed pipe 8 and a central cylinder 4 located in the center of the feed pipe 8 for air intake. The end of the central cylinder 4 is connected with a swirl injector 6 , the gas enters from the central cylinder 4 and is discharged from the end air outlet of the swirl injector 6. The swirl injector 6 is as image 3 shown. The outside of the feed pipe 8 is successively fitted with a partition pipe 3 with an increased diameter and an air cavity pipe 1, the partition pipe 3 is an annular channel, and the front end of the feed pipe 8 is provided with a swirl mixer 5, such as figure 2 As shown, the swirl mixer 5 is provided with several deflectors 51 arranged circumferentially between the two concentric rings 52, 53, so that the air flow between the feed pipe 8 and the dividing pipe 3 is discharged in a swirling flow, and the swirling The deflector 51 of the flow mixer 5 is inclined along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com