Micro oil pulverized coal burner

A pulverized coal burner and micro-oil technology, which is applied to burners, burners burning powder fuel, combustion types, etc., can solve the problem of inability to control the distribution of pulverized coal concentration, prevent the flame from scouring the wall surface and overheat, and is conducive to The effect of ignition and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

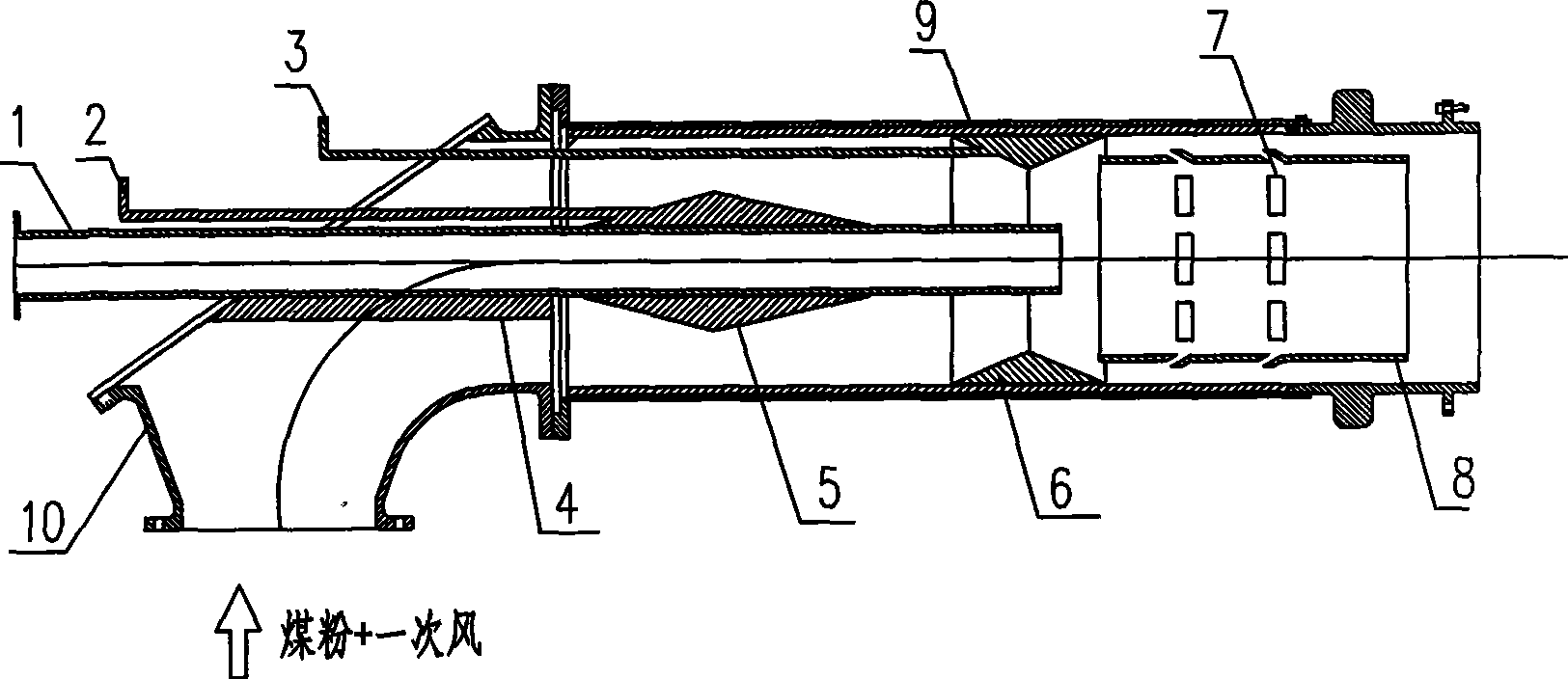

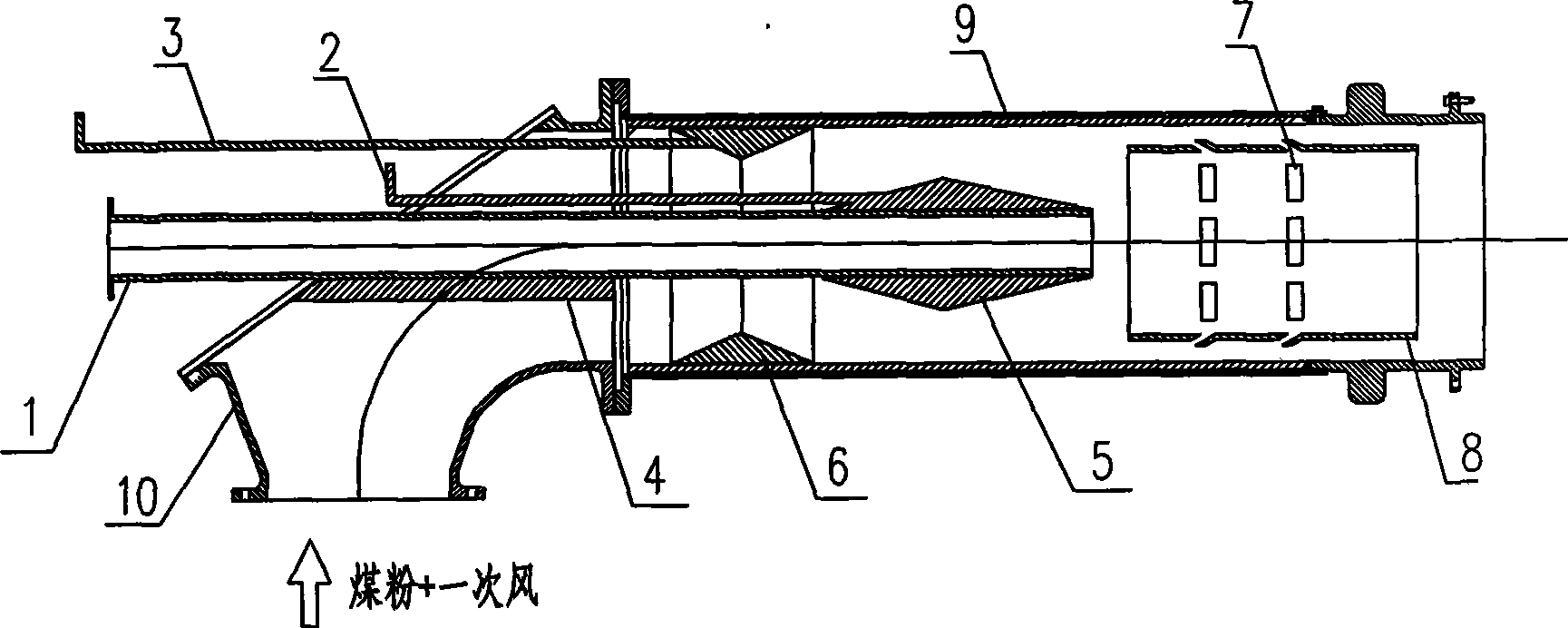

[0015] Example 1, as figure 1 , 2 As shown, a micro-oil pulverized coal burner includes an elbow 10 with a coal powder inlet and a primary air duct 9 connected thereto. At least one telescopically movable concentrator 5 is arranged on the outer wall of the micro oil gun 1 , and at least one telescopically movable guide ring 6 is arranged on the inner wall of the primary air duct 9 .

[0016] The structure of the telescopically movable concentrate 5 is such that the concentrate is connected to the inner pull rod 2, which can be pushed or pulled out manually or automatically by an actuator. The deflector ring 6 that can move telescopically is constructed such that the deflector ring is connected to the outer pull rod 3, and is pushed or pulled out manually or automatically by an actuator.

[0017] The cross-sectional shapes of the concentrated body 5 and the guide ring 6 are triangular, trapezoidal or streamline.

Embodiment 2

[0018] Embodiment 2, a kind of micro-oil pulverized coal burner, in order to ensure that the air-powder mixture outside the center cylinder 9 can enter the center cylinder, and the inner wall is cooled, the wall surface of the center cylinder is protected, and the phenomenon of high temperature burning loss is prevented from occurring. An air film tuyere 7 is also opened on the top. The rest are the same as in Example 1.

Embodiment 3

[0019] Embodiment 3, a micro-oil pulverized coal burner, in order to reduce the erosion and erosion of the micro-oil oil gun by the coal powder, a wear-resistant plate is also provided at the lower part of the micro-oil oil gun in the elbow.

[0020] The working principle of the present invention: as figure 1 As shown, when in the light oil ignition mode, manual or actuator action pushes the pull rod connecting the deflector ring, so that the deflector ring is located at the front end of the primary air duct. Manual or actuator action pulls the rod connecting the concentrate, so that the concentrate retreats to the rear of the oil barrel. The concentrated pulverized coal is led into the central guide cylinder and gathered around the outlet of the oil gun combustion cylinder, so that the high-concentration air-powder mixture is conducive to being ignited by the oil gun flame. When used as the main burner, that is, under normal operation of the boiler, such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com