Improved plasma ignition nozzle of coal dust gasifier and mode

A plasma ignition and gasification furnace technology, applied in the direction of combustion ignition, incandescent ignition, combustion methods, etc., can solve the problems of insufficient fuel combustion, high production, use and maintenance costs, pollution, etc., to save fuel and gas costs, fuel Convenient storage and management, the effect of overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the composition and implementation of the present invention clear to your examiner, the description is as follows in conjunction with the drawings:

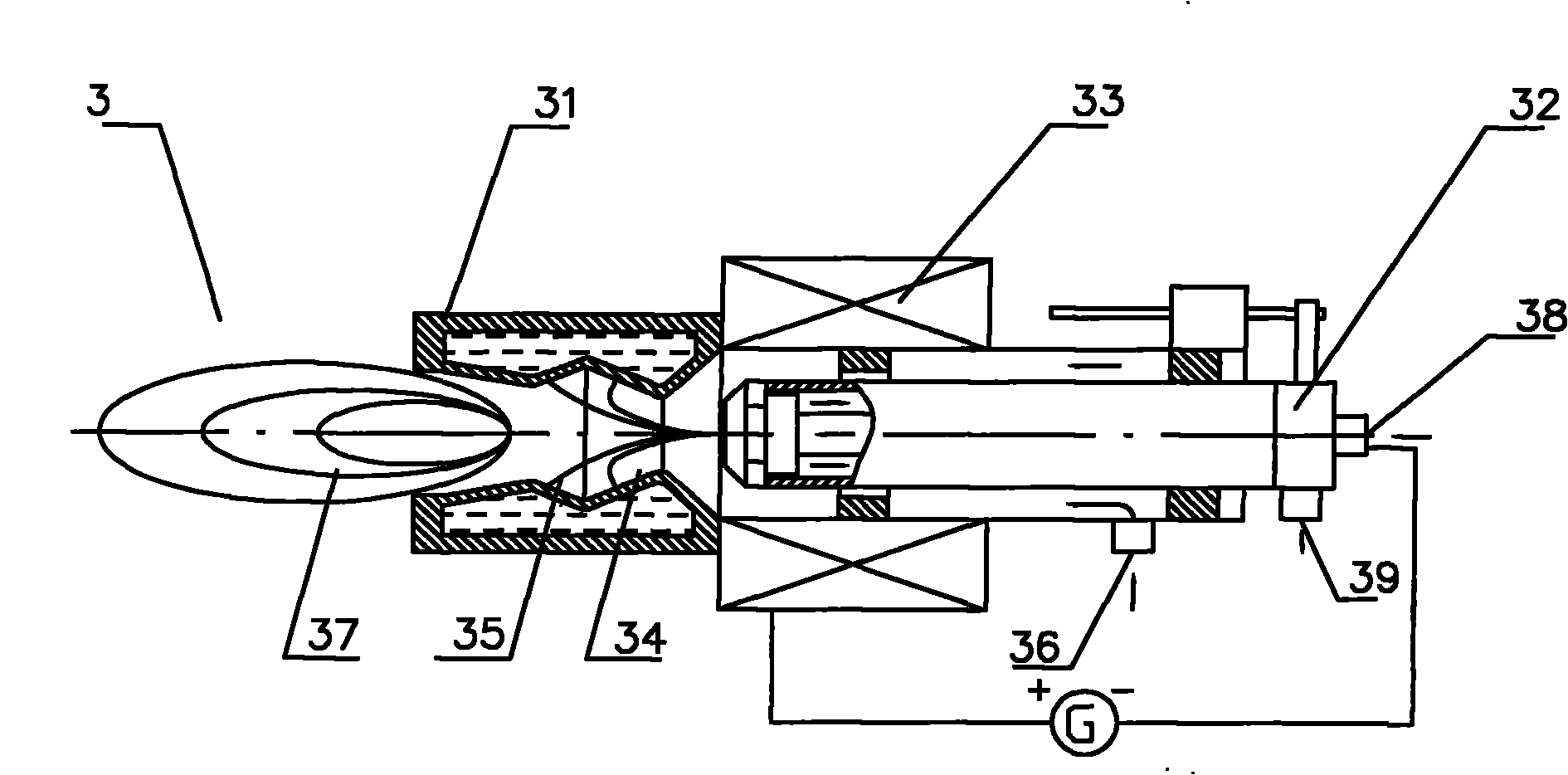

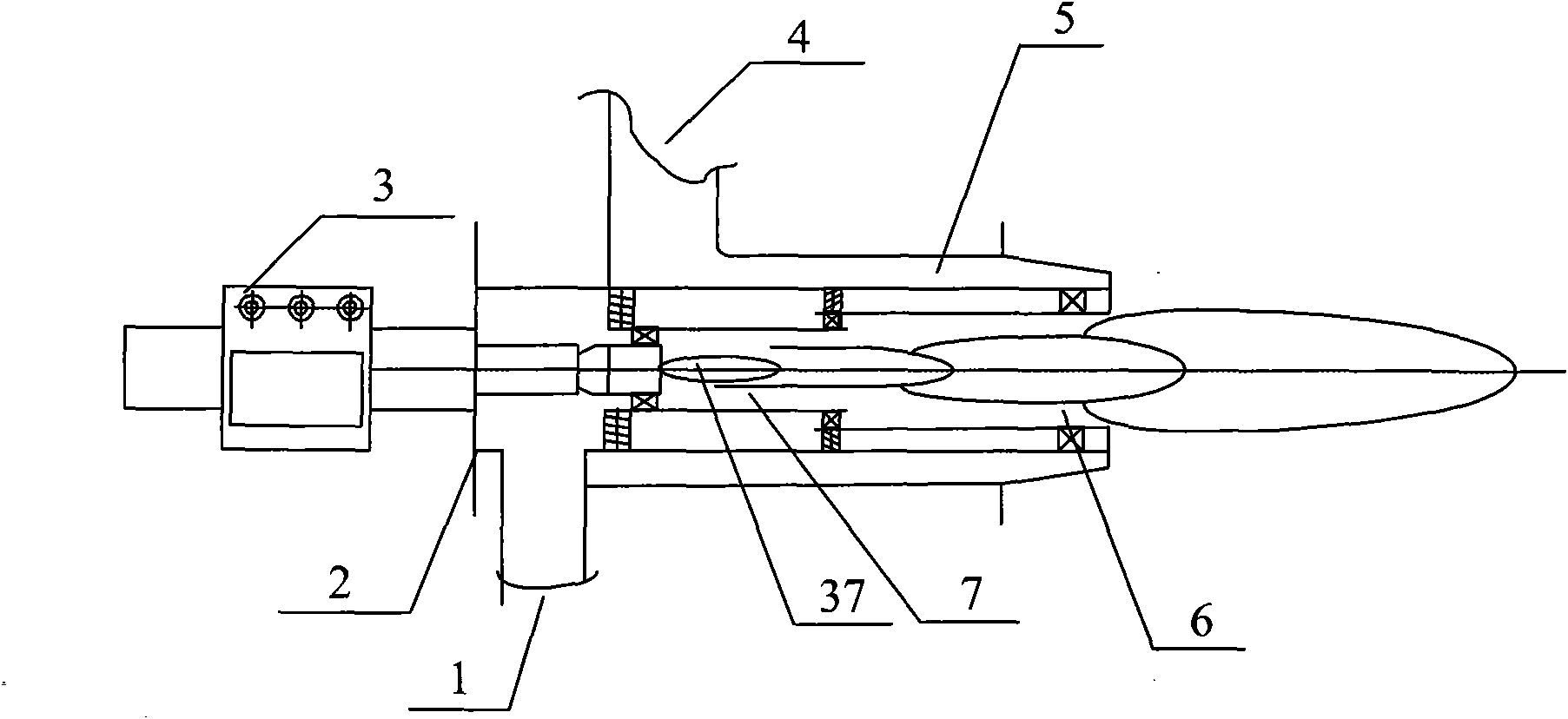

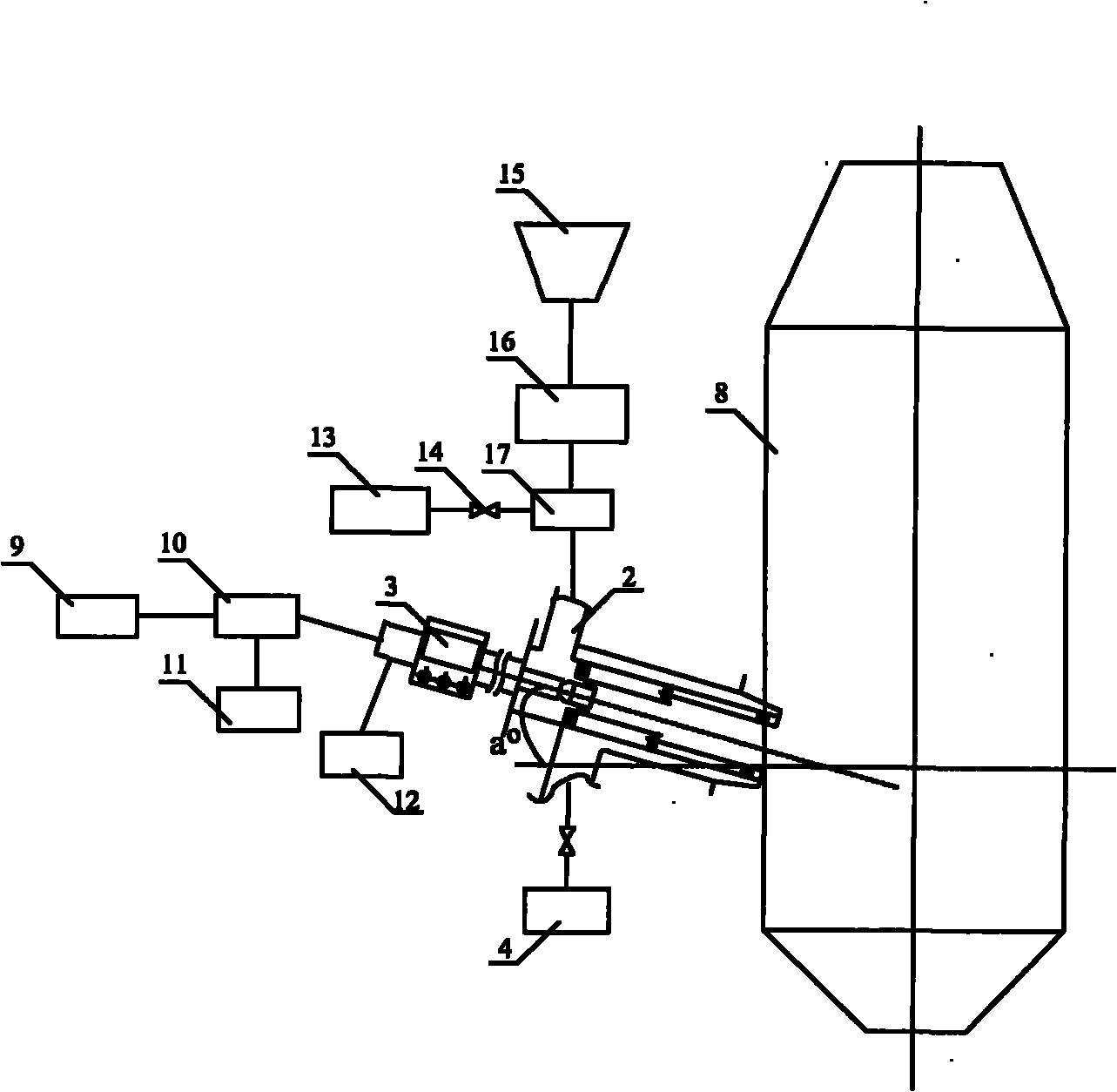

[0025] At low furnace temperature, because the powder-containing jet cannot be heated and ignited by the hot flue gas in the entrainment furnace, it must rely on its own flame propagation to make the jet all ignite. Therefore, in order to use the plasma ignition technology, the original starting nozzle of the gasifier needs to be Transformation, the structure of the modified plasma ignition nozzle is as follows figure 2 As shown, the characteristics are: the geometrical dimensions of the original start-up nozzle of the gasifier are the same; the momentum moment of the airflow at the outlet of the original start-up nozzle remains similar; and the principle of multi-stage amplification is applied, and the plasma ignition device consists of plasma generator 3 The plasma ignition nozzle 2, the outer sleeve 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com