Self-cleaning, continuously operating filter apparatus for fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

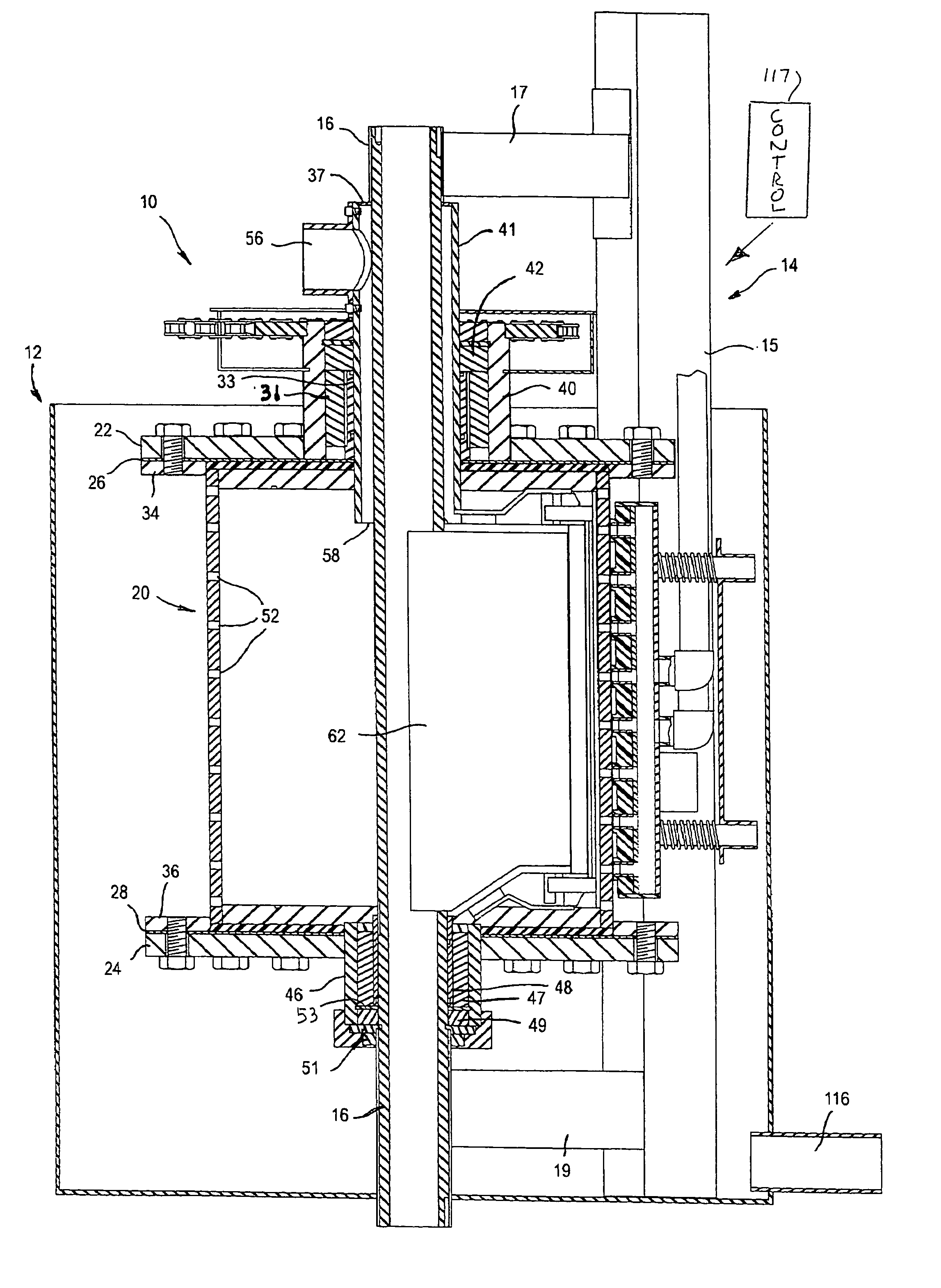

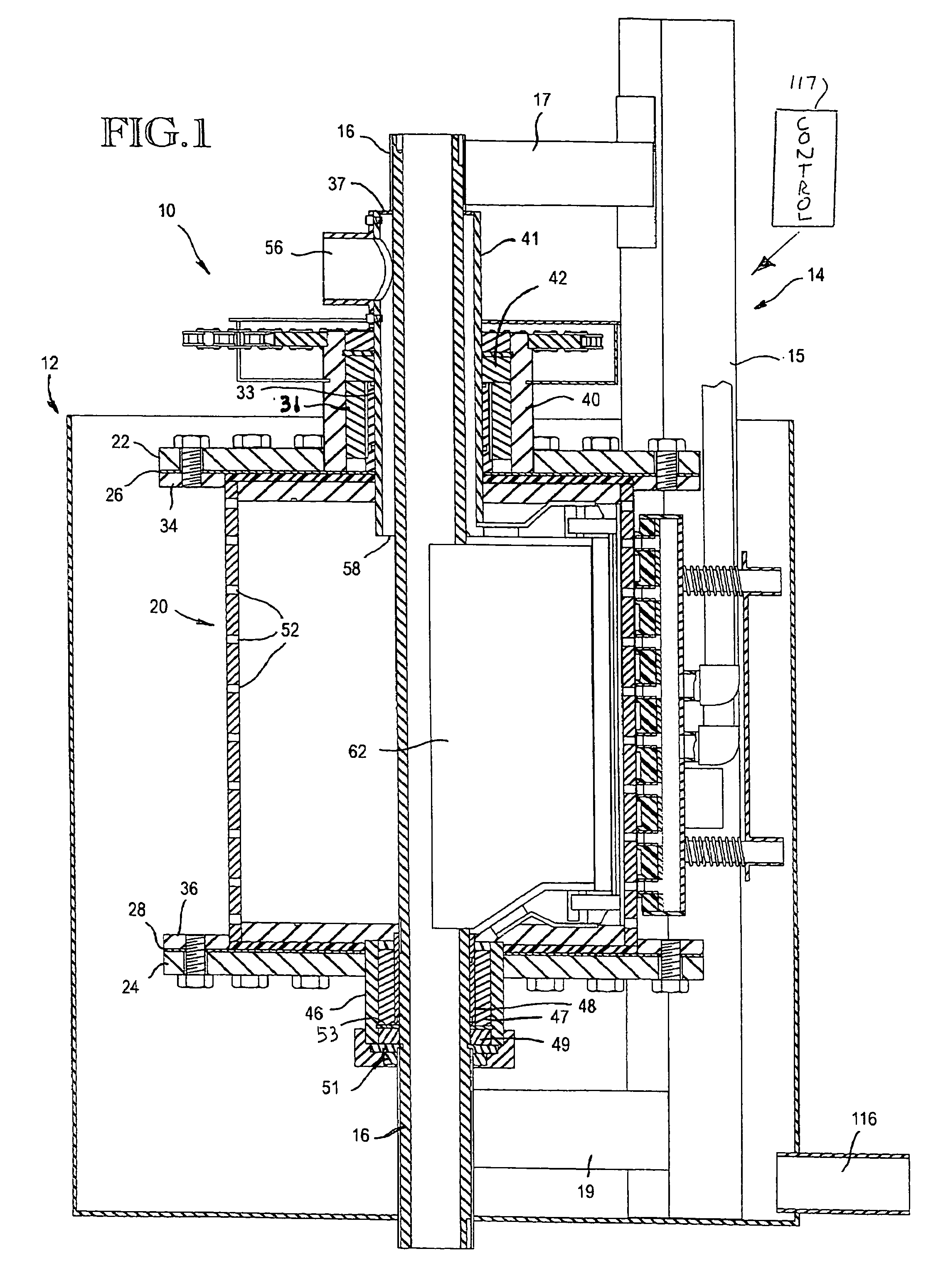

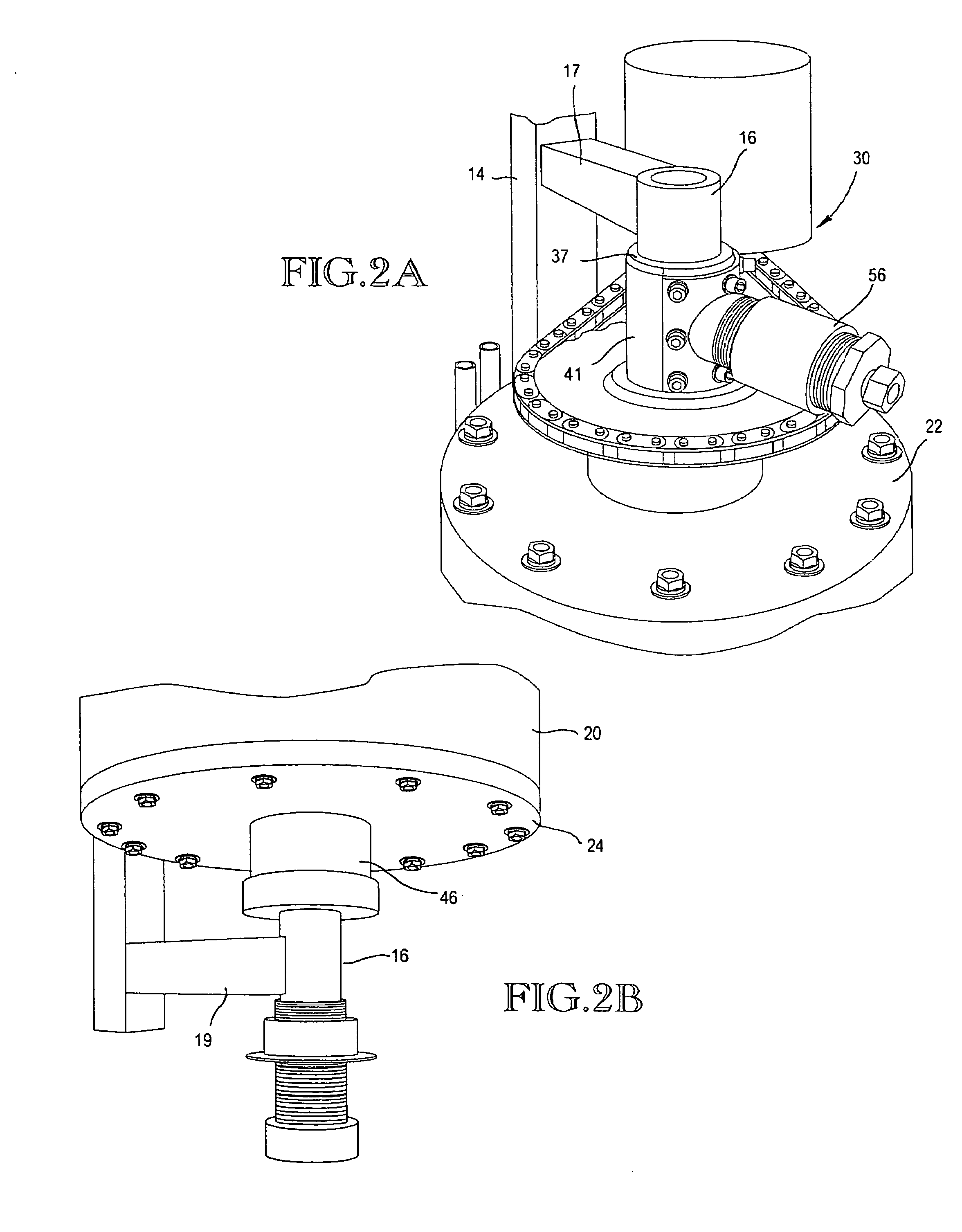

[0014]FIG. 1 shows an overall environmental view of the filter apparatus 10 disclosed herein. The apparatus 10 is used to separate selected elements from an incoming untreated liquid or other fluid. The description herein will focus on a liquid application. In some cases, the separated elements (the retentate) are retained and the treated liquid (permeate) disposed of, while in other cases, the retentate is disposed of and the liquid is retained, typically for re-use. The present apparatus can be used in a variety of industries and applications; however, the description herein, which should not be considered limiting, is directed toward a laundry application, in which a particular retentate, lint, is filtered (removed) efficiently from laundry waste water, permitting re-use of the waste water, following additional conventional steps to remove other elements / pollutants which would otherwise prevent re-use.

[0015]The apparatus 10 shown and described includes a housing, generally identi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com