Insulated wire stripper

A wire stripper and insulated wire technology, which is applied in the direction of line/collector parts, cable installation devices, electrical components, etc., can solve the inconvenience of operation, the inability to complete the circular cutting of cables, and the inability to accurately judge whether the insulation layer is completely cut through and other problems, to achieve the effect of controllable cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

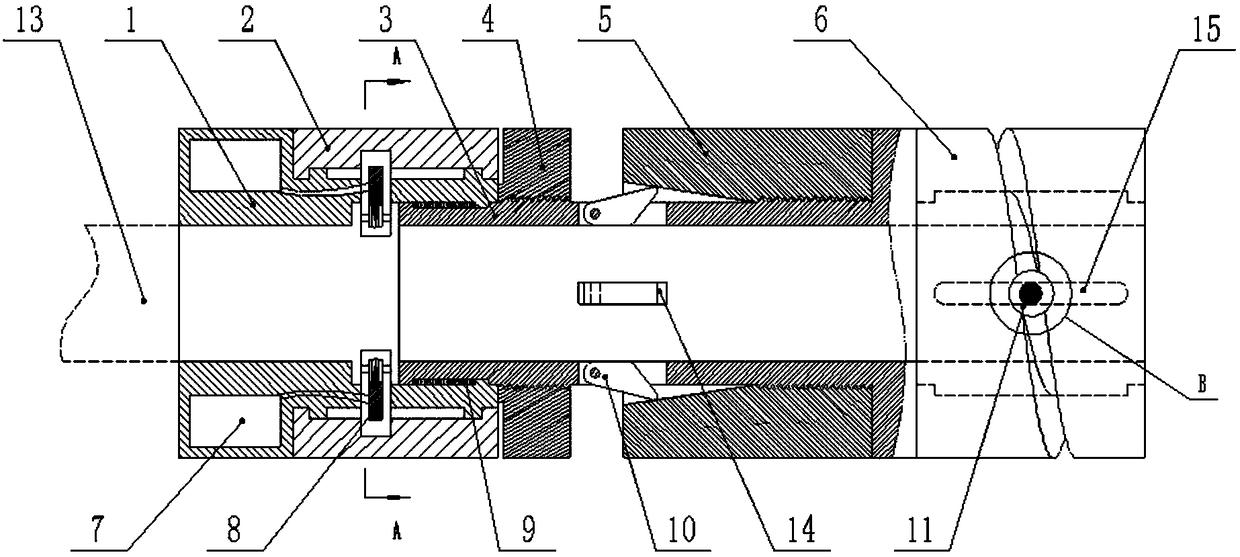

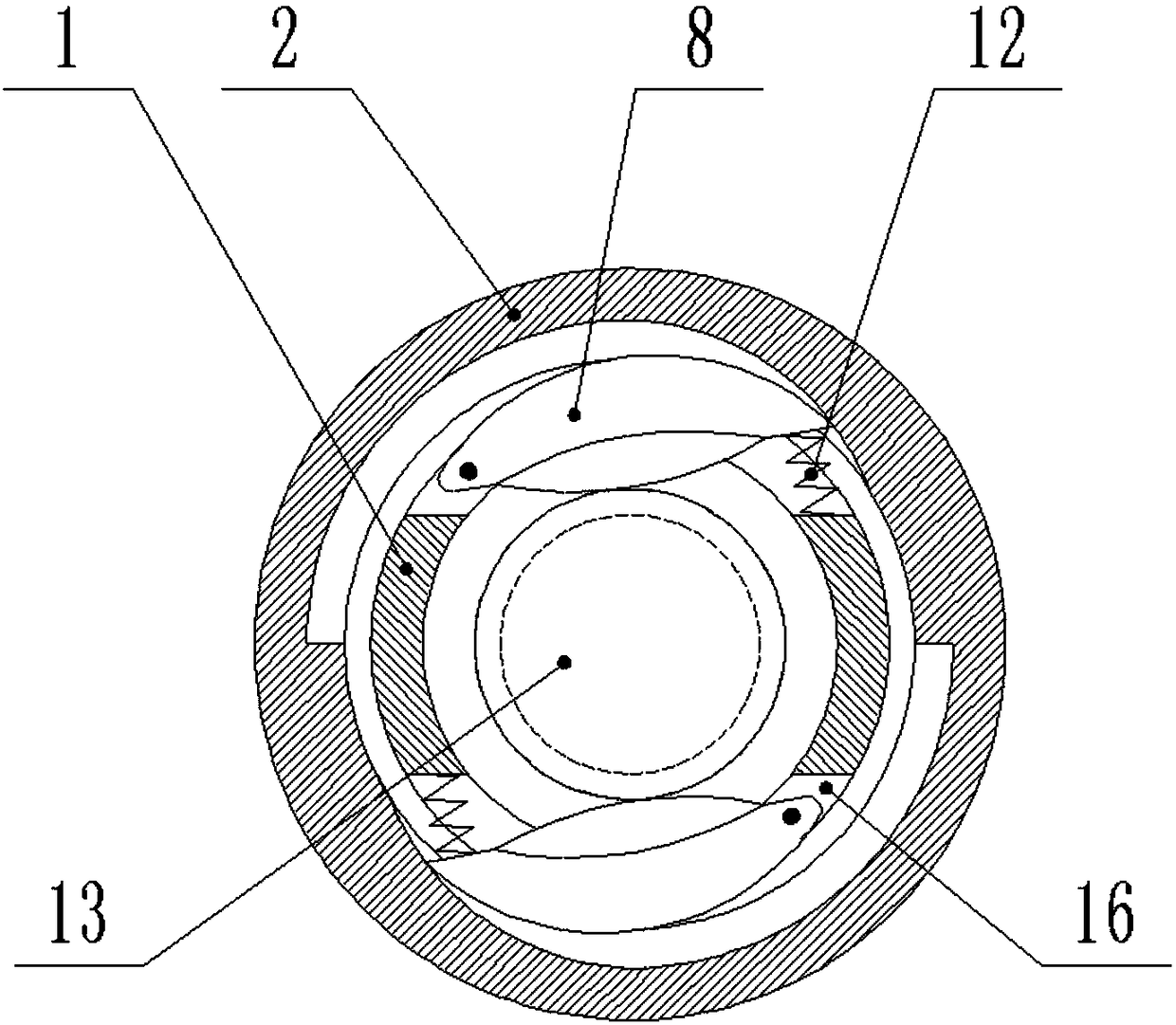

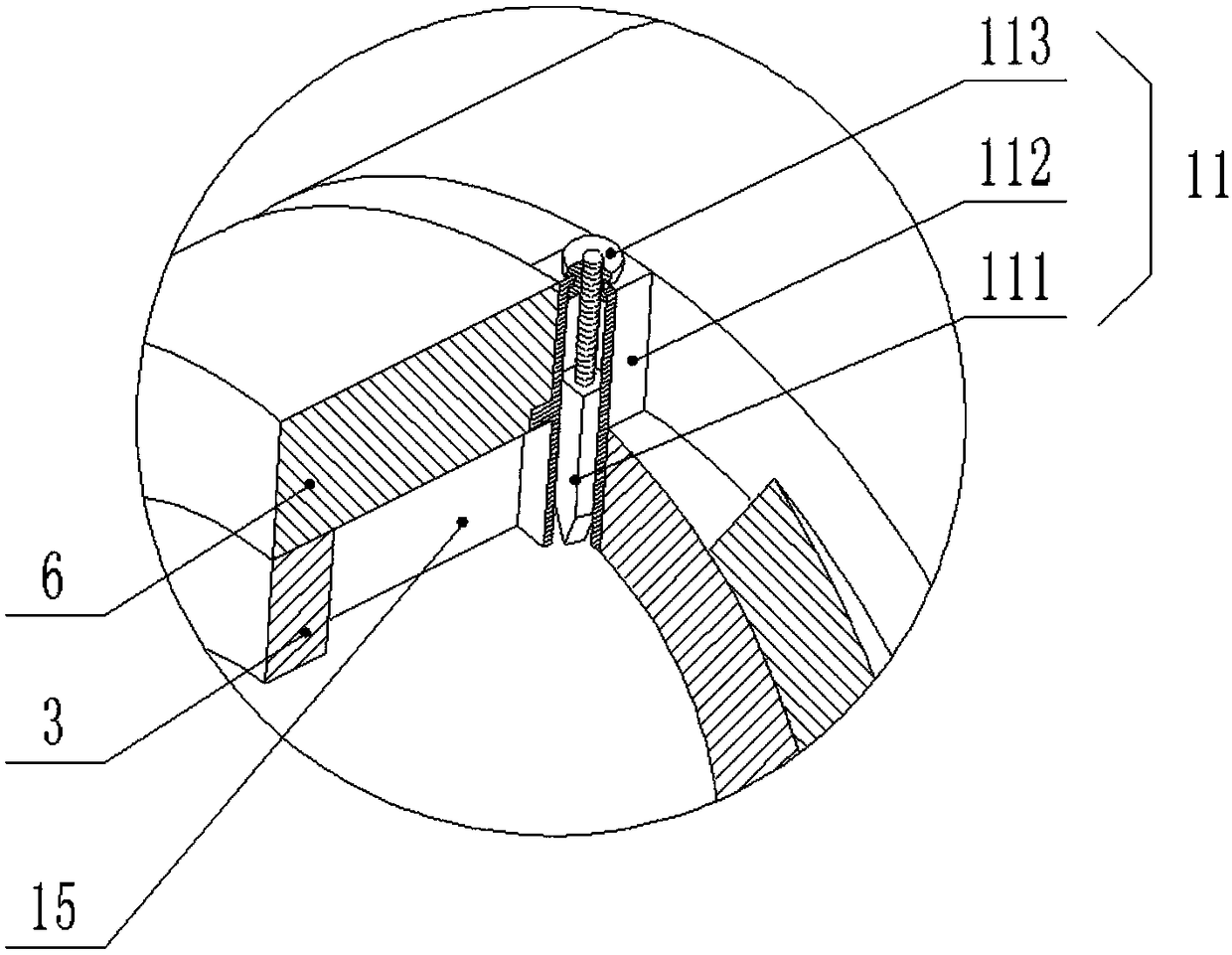

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] An insulated wire stripper, including an inner cylinder 3, the outer ring of the inner cylinder 3 is sequentially fitted with a middle sleeve 1, an ejection sleeve 4, a clamping sleeve 5, and a slitting sleeve 6 , the middle sleeve 1 can rotate along the circumference of the inner cylinder 3 and can also slide along its axial direction. An annular cavity is provided at the joint between the middle sleeve 1 and the inner cylinder 3, and a top is set in the annular cavity. The ejection spring 9, the ejection spring 9 is in a compressed state, the two ends of the ejection spring 9 are respectively abutted against the ring boss at the end of the middle sleeve 1 and the inner cylinder 3, and the ejection sleeve 4 is rotated counterclockwise The ejection sleeve 4 will move to the left, so that the middle sleeve 1 will overcome the elastic force of the ejecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com