Experimental apparatus and experimental method for simulating gas-well annulus pressure carrying and air cutting processes

A technology with annular pressure and experimental methods, which is applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as unclear pressure change law, induced well kick, gas kick, etc., and achieve strong popularization and application The effect of value, reliable performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

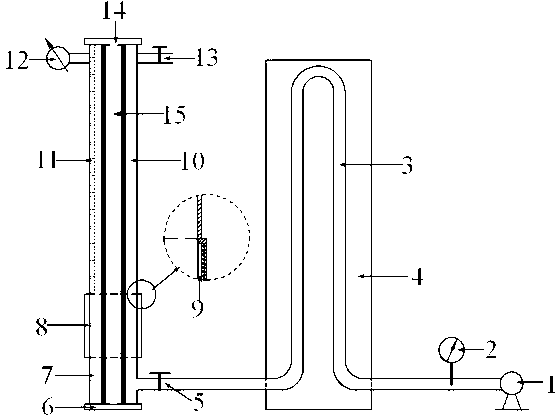

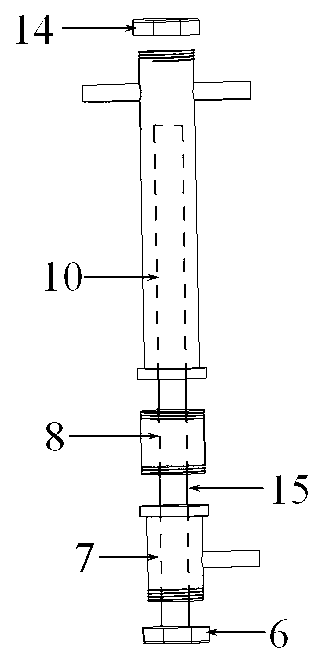

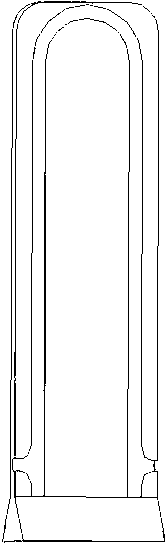

[0022] Example 1: When simulating the process of gas well annulus under pressure, first install the central cylinder, connect the lower sealing cover 6 with the lower air intake cylinder 7, and the lower sealing cover 6 and the central column 15 form an integral structure, and the upper end of the lower air intake cylinder 7 It is connected with the core holding cylinder 8, and the rubber sleeve 9 is placed on the inner wall of the core holding cylinder 8. The thickness of the rubber sleeve 9 is just the difference between the inner diameter of the core holding cylinder 8 and the inner diameter of the upper pressure measuring cylinder 10, so that the pad The inner diameter of the core holding cylinder 8 with the rubber sleeve 9 is the same as the inner diameter of the upper pressure measuring cylinder 10 and the lower air inlet cylinder 7, and then the polished annular core is placed outside the center column 15 and placed in the core holding cylinder 8 Fixed, the other end of ...

Embodiment 2

[0023]Example 2: When simulating the gas invasion process, first install the central cylinder, connect the lower sealing cover 6 with the lower air intake cylinder 7, and the lower sealing cover 6 and the central column 15 form an integral structure, and the upper end of the lower air intake cylinder 7 is connected to the core clamp The holding cylinder 8 is connected, and the rubber sleeve 9 is placed on the inner wall of the core holding cylinder 8. The thickness of the rubber sleeve 9 is just the difference between the inner diameter of the core holding cylinder 8 and the inner diameter of the upper pressure measuring cylinder 10, so that the rubber sleeve is cushioned. The inner diameter of the core holding cylinder 8 of 9 is the same as the inner diameter of the upper end pressure measuring cylinder 10 and the lower end air inlet cylinder 7, the other end of the rock core holding cylinder 8 is connected with the upper end pressure measuring cylinder 10, and the upper end pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com